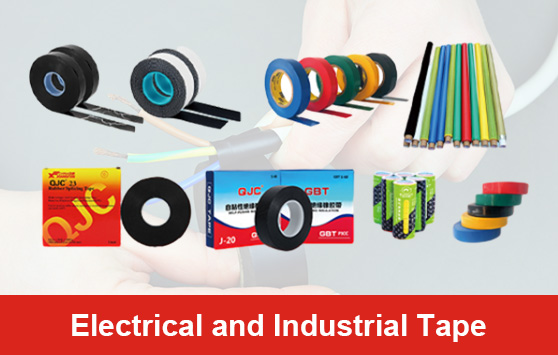

When setting up your cables and electronics, chances are you use different cable management tools to help manage it all. Electrical insulation tape is a common material used by folks overseeing cable organization to cover and insulate wires using electricity. Manufacturers have developed different types of electrical tapes ranging in thickness, widths, and lengths for varying technical purposes. Before setting up your network and organizing your cables, get familiar with everything you need to know about electrical tape.

What Is Electrical Tape

If you’re unfamiliar with reasons why people use electrical tape over other more basic tapes, there are a few factors that make it stand out among the rest:

- It is an effective insulator against electricity, protecting circuitry and users by not transmitting currents.

- It is heat-resistant and fireproof, improving the fire safety of any facility that uses it with their electrical devices.

- It is flexible and user-friendly, making cable connection and insulation a breeze.

The Different Types of Electrical Insulation Tape and Their Uses

What is electrical taped used for? Electrical tape has many uses and is categorized into four different varieties. Read on to discover what differentiates rubber, vinyl, mastic, and varnished cambric.

RUBBER

Rubber tape usually does not have an adhesive side but sticks to itself. This means it has to be stretched entirely around a cable to effectively adhere to itself using elastic tension against the backing.

The rubber is water-resistant, a highly appreciated perk to those working in humid environments. Rubber tape is usually used for splicing and terminating wires or cables up to 69 kilovolts.

VINYL

The most common type of electrical insulation tape used in the home, vinyl tape is used for insulation, protection from moisture, and repairing minor nicks and cuts.

It has an abrasion-resistant backing that lasts long and has flexibility, which makes it a prime option for insulating electrical connections during electrical tapping.

MASTIC

Mastic tape is the portion that composes the spongey center between the backing and the adhesive. If you need versatility with your projects, mastic tape is the way to go. You can find mastic that has vinyl backing, rubber backing, or no backing.

Since it’s an affable tape, it’s popular amongst electricians. It adheres easily and can get manipulated to fit in tight spaces and around oddly shaped materials. Mastic tape is a highly revered choice for outdoor wiring needs, as it has excellent moisture and UV resistant capabilities.

VARNISHED CAMBRIC

Varnish cambric electrical insulation tape is made of straight-cut woven cotton fabric. Its fabric is primed with oil and coated in an electrical insulating finish. The varnish ensures that the tape remains intact as currents pass through the wire.

Varnished cambric tape is often employed to cover bolts, corners, and rough edges that could cut through less durable tape. It’s the ideal candidate for mechanical protection and puncture resistance around your home, vehicle, or office.

What the Different Colors of Electrical Insulation Tape Mean

When you think of types of electrical tape, you probably imagine it in black. However, manufacturers produce electrical insulation tape in almost every color of the rainbow. The varying colors indicate voltage protection and insulation. It’s vital to use the right colored tape—an incorrect tape color puts technicians at risk of insufficient voltage shielding:

- Black: Many technicians default to black insulation tape for insulation of cable connections. Black tape often gets marked with color-coded phasing tape. A ring of colored tape gets wrapped near each termination end to clearly indicate the purpose of each wire.

- White: White electrical tape is often used to signify “low voltage, neutral.”

- Blue: Internationally, blue tape indicates “low voltage, neutral sheath, 230V”

- Green: In the US, green tape means “earth ground.” It’s common for green and yellow tape to be used together to imply “isolated ground.”

- Brown: Brown tape signifies “high voltage, phase A.”

- Yellow: Yellow symbolizes “high voltage, phase C.”

- Red: Typically, red tape means “low voltage, phase B.”

- Grey: The standard implication of grey tape is “low voltage, phase C.”

What To Consider When Choosing Your Tape

In understanding everything you need to know about electrical tape, you should learn a thing or two about tape selection. So, what should you reflect on when choosing which type of electrical tape to use for your network? CableWholesale looks at other elements of electrical tape to consider when investing.

TAPE GRADE

Backing construction, thickness, and dielectric strength are factors of a tape’s grade. The grade is highly indicative of its performance quality. Tape backings are either monomeric or polymeric, polymeric being the more durable of the two.

Choosing high-grade tapes can increase cable longevity because they are highly durable, tightly sealed, and prevent corrosion. Reflect on your network’s environment to determine which grade will be necessary.

COLOR

As mentioned, different colors indicate different types of electrical tape features. Many standard electrical tapes are sold in black, but you can find them in nearly every color. Choose the color of tape based on the application you will be using it for and its voltage, phase, and other electric-relevant information.

TAPE STRETCH

Many technicians opt for tape that can stretch without losing original form. This is helpful in wrapping wires because technicians must often stretch the tape around the cable, which needs to then return to its original form to provide a tight wrap. Lack of elongation can result in broken tape and uncovered cables.

EASE OF USE

Organizing cables can be a cumbersome task. Avoid exacerbating your frustration by choosing an easy-to-use electrical tape. The tape should be easy to handle. Check to see that the tape can be torn by hand and easily wrapped around wires. Its adhesive should be strong enough to withstand the conditions of where it will be located.

CODE COMPLIANCE

Familiarize yourself with your area’s building codes. Select tapes that have been meticulously tested for reliability to ensure you’re getting tools that are worthy of your investment. It’s a good idea to opt for these tapes, too, as they are most likely to comply with building code.

FOR YOUR CABLE MANAGEMENT CONSIDERATION

In addition to using electrical tape, CableWholesale offers cable wraps, runners, straps, and ties to keep your reliable 1000ft Cat5e cable bundles organized. We have all the digital accessories your network needs to function effectively and, most importantly, safely. Check out our inventory today to learn which supplies can enhance your connection setup.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsZprávyJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsZprávyJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsZprávyJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeZprávyJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesZprávyJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationZprávyJun.24,2025