The Versatility and Utility of Plastic Electrical Tape

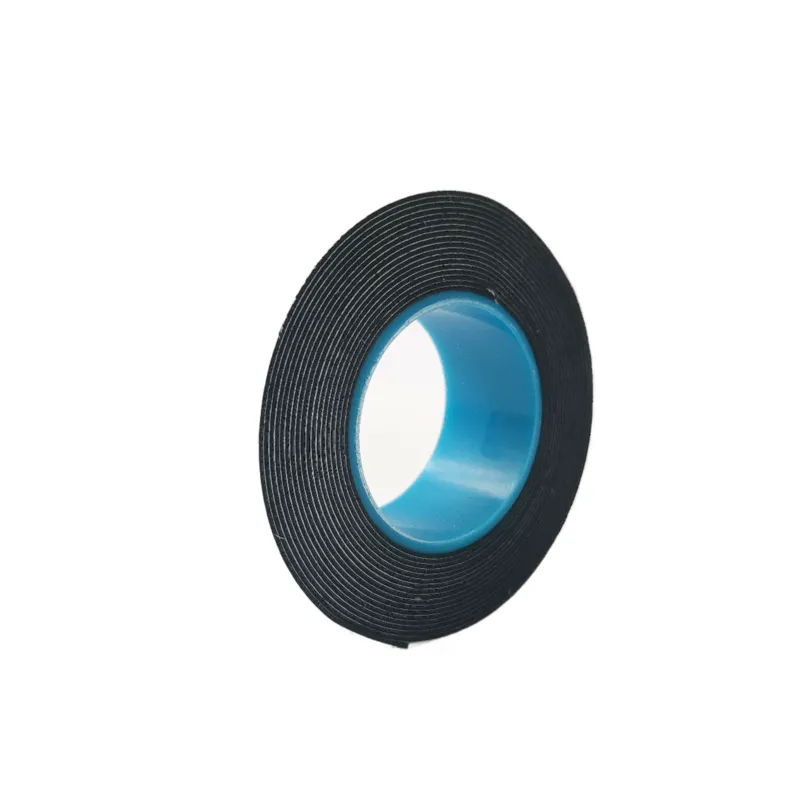

Plastic electrical tape is a staple in the toolbox of electricians, DIY enthusiasts, and anyone involved in electrical wiring and repair. This versatile adhesive tape, often made from PVC (polyvinyl chloride), offers a range of features that make it indispensable for various electrical applications. From insulation to color coding wires, its applications are vast and varied.

Key Features of Plastic Electrical Tape

One of the most significant attributes of plastic electrical tape is its excellent insulating properties. The material is designed to withstand high voltage, which is crucial in preventing electrical shocks and short circuits. Unlike traditional cloth or paper tapes, plastic electrical tape provides a more reliable barrier against electrical current, ensuring safety in electrical installations.

Additionally, plastic electrical tape is resistant to environmental factors such as moisture, oil, and UV light. This makes it suitable for both indoor and outdoor use. Whether it’s for repairing cords in your home or securing electrical connections in outdoor fixtures, this tape can withstand the elements and maintain its performance over time.

Another feature worth mentioning is its flexibility. The tape can conform to various shapes and surfaces, allowing for easy application even in tight spaces. This flexibility is especially beneficial when dealing with irregularly shaped objects or when needing to wrap around corners and edges.

Applications of Plastic Electrical Tape

Plastic electrical tape is extensively used in electrical insulation. When wrapping wires, the tape acts as a protective layer, preventing accidental contact with other conductive materials. This is crucial for ensuring that devices operate safely and efficiently, particularly in complex wiring systems found in homes or commercial buildings.

plastic electrical tape

Moreover, one of the fascinating uses of plastic electrical tape is color coding

. Different colors of tape can indicate specific functions or types of wires, making it easier to identify connections during repairs or installations. For instance, black tape might signify a hot wire, while green tape could indicate a ground wire. This system of color coding enhances safety and expedites the troubleshooting process.Plastic electrical tape is also utilized in the field of auto repair. Mechanics often use it for insulating electrical connections in vehicles, ensuring that sensitive parts remain protected from corrosion and damage. Additionally, it can serve as a temporary fix for frayed wires or damaged insulation until a more permanent solution can be applied.

Best Practices for Using Plastic Electrical Tape

When using plastic electrical tape, it is important to follow a few best practices to ensure maximum effectiveness. First, always clean the surface before applying the tape. Dirt or grease can hinder adhesion, reducing the tape's insulating properties.

Second, it's advisable to apply the tape with a slight overlap. Wrapping it around the wire or the object you are protecting ensures that there are no exposed areas, which could lead to electrical leakage.

Finally, avoid stretching the tape too much as you apply it. While the tape is designed to be flexible, pulling it too tight can compromise its insulating properties and lead to premature wear and tear.

Conclusion

Plastic electrical tape is an essential tool in the arsenal of anyone working with electricity. Its insulating properties, resistance to environmental conditions, and flexibility make it perfect for a wide range of applications from insulation to repair. Understanding how to use it effectively can enhance safety and efficiency in various projects, making it a must-have in every toolkit. Whether you are a seasoned professional or a weekend warrior tackling home improvement projects, plastic electrical tape is an investment in safety and reliability that you won't want to go without.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025