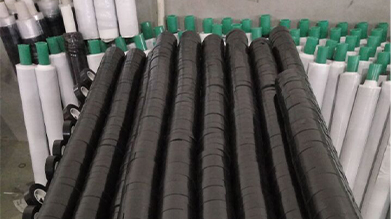

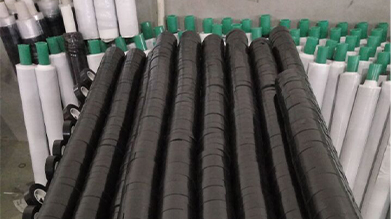

130C linerless rubber splicing tape for high temperature applications and electrical insulation

Back to list

Jul . 10, 2024 20:46

Rubber splicing tape is a crucial tool in the field of industrial maintenance and repair. One popular type of splicing tape is the 130c% linerless rubber splicing tape, which offers numerous benefits and advantages for those who utilize it.

This type of splicing tape is designed to provide a strong and reliable bond between two pieces of rubber or other materials. It is able to withstand high temperatures up to 130 degrees Celsius, making it ideal for use in a variety of industrial applications where heat may be a factor.

One of the key advantages of 130c% linerless rubber splicing tape is its ease of use. Unlike traditional splicing tapes that require a liner to be removed before application, this tape can be applied directly without the need for any additional steps. This saves time and increases efficiency, making it a popular choice among maintenance professionals.

Additionally, the strong adhesive properties of this tape ensure a secure bond that will hold up under even the most demanding conditions

130c linerless rubber splicing tape. Whether used for electrical insulation, sealing, or bonding, the 130c% linerless rubber splicing tape provides a reliable and long-lasting solution. Another key benefit of this type of splicing tape is its versatility. It can be used on a wide range of materials, including rubber, plastic, and metal, making it a versatile tool for a variety of maintenance and repair tasks. Additionally, it is resistant to water, oil, and chemicals, ensuring that it will hold up well in harsh industrial environments. Overall, 130c% linerless rubber splicing tape is an essential tool for maintenance professionals who work with rubber and other materials on a regular basis. Its high temperature resistance, ease of use, strong adhesive properties, and versatility make it a valuable asset in any industrial setting. Whether used for electrical insulation, sealing, or bonding, this tape delivers reliable results that stand the test of time.

130c linerless rubber splicing tape. Whether used for electrical insulation, sealing, or bonding, the 130c% linerless rubber splicing tape provides a reliable and long-lasting solution. Another key benefit of this type of splicing tape is its versatility. It can be used on a wide range of materials, including rubber, plastic, and metal, making it a versatile tool for a variety of maintenance and repair tasks. Additionally, it is resistant to water, oil, and chemicals, ensuring that it will hold up well in harsh industrial environments. Overall, 130c% linerless rubber splicing tape is an essential tool for maintenance professionals who work with rubber and other materials on a regular basis. Its high temperature resistance, ease of use, strong adhesive properties, and versatility make it a valuable asset in any industrial setting. Whether used for electrical insulation, sealing, or bonding, this tape delivers reliable results that stand the test of time.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025