Understanding Rubber Tape The Versatility of Self-Fusing Solutions

Rubber tape, particularly self-fusing rubber tape, has gained considerable attention in recent years for its unique properties and diverse applications. Unlike traditional tapes, which rely on adhesives to stick to surfaces, self-fusing tape operates on a different principle - it bonds to itself upon contact, creating a durable, waterproof seal. This characteristic makes it an invaluable tool in various industries, from electrical work to plumbing and beyond.

What is Self-Fusing Rubber Tape?

Self-fusing rubber tape is typically made from a synthetic rubber compound that allows it to stretch, conform, and thus mold itself to irregular shapes. When two ends of the tape are pressed together, they bond without the need for adhesive, creating a seamless, strong layer. The tape's fusion process not only ensures a tight fit but also makes it resistant to moisture, chemicals, and extreme temperatures.

Key Features and Benefits

1. Waterproof and Weatherproof One of the standout features of self-fusing rubber tape is its ability to resist water ingress. It is perfect for protecting electrical connections, exposed wiring, and other sensitive installations from moisture, making it a go-to solution for outdoor applications.

2. Versatile Application This tape finds use in a wide range of areas, including automotive repair, electrical maintenance, plumbing, and even hobby projects. It's particularly useful for emergency repairs, allowing quick fixes without the need for specialized tools or materials.

3. Temperature Resistance Self-fusing rubber tape can withstand extreme temperatures, typically ranging from -40°F to over 200°F. This temperature resilience means it can be used effectively in both cold and hot environments, making it ideal for versatile applications.

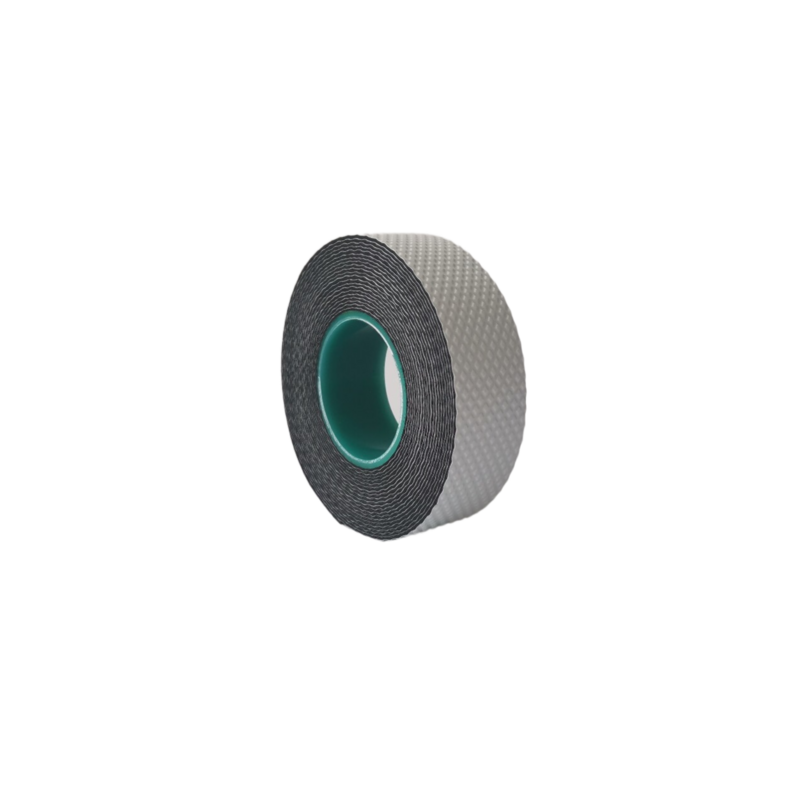

rubber tape self fusing

4. Durability Once fused, the tape forms a robust bond that can endure significant mechanical stress without peeling or tearing. This durability is crucial in industrial settings where reliability is paramount.

5. Easy to Use Applying self-fusing tape is straightforward. The user simply wraps the tape around the desired area, overlapping each layer by at least half. As the tape touches itself, it begins to bond, creating a secure seal. This ease of application makes it accessible for both professionals and DIY enthusiasts.

Common Applications

- Electrical Insulation Self-fusing rubber tape is widely used for insulating electrical wires and connections. It provides a safe barrier against water and other contaminants, ensuring that electrical systems operate effectively and safely.

- Plumbing Repairs Leaks in pipes can lead to extensive damage if not addressed promptly. Self-fusing tape can quickly seal leaks in both plastic and metal pipes, providing a temporary fix until permanent repairs can be made.

- Hose Repairs If a hose develops a crack or puncture, self-fusing tape can be applied to mend it. This application is useful in situations ranging from garden hoses to more critical systems in vehicles.

Conclusion

In conclusion, self-fusing rubber tape exemplifies the innovation and practicality needed in today's fast-paced world. Its unique characteristics not only allow for a wide range of applications but also promise reliability and durability in challenging environments. Whether you are a professional tradesperson or a DIY enthusiast, incorporating self-fusing rubber tape into your toolkit can empower you to tackle repairs and projects with confidence. As industries continue to evolve, the demand for versatile, effective solutions like self-fusing rubber tape will only increase, solidifying its place as a cornerstone material for countless applications.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025