splicing tape

Back to list

កុម្ភៈ . 12, 2025 09:45

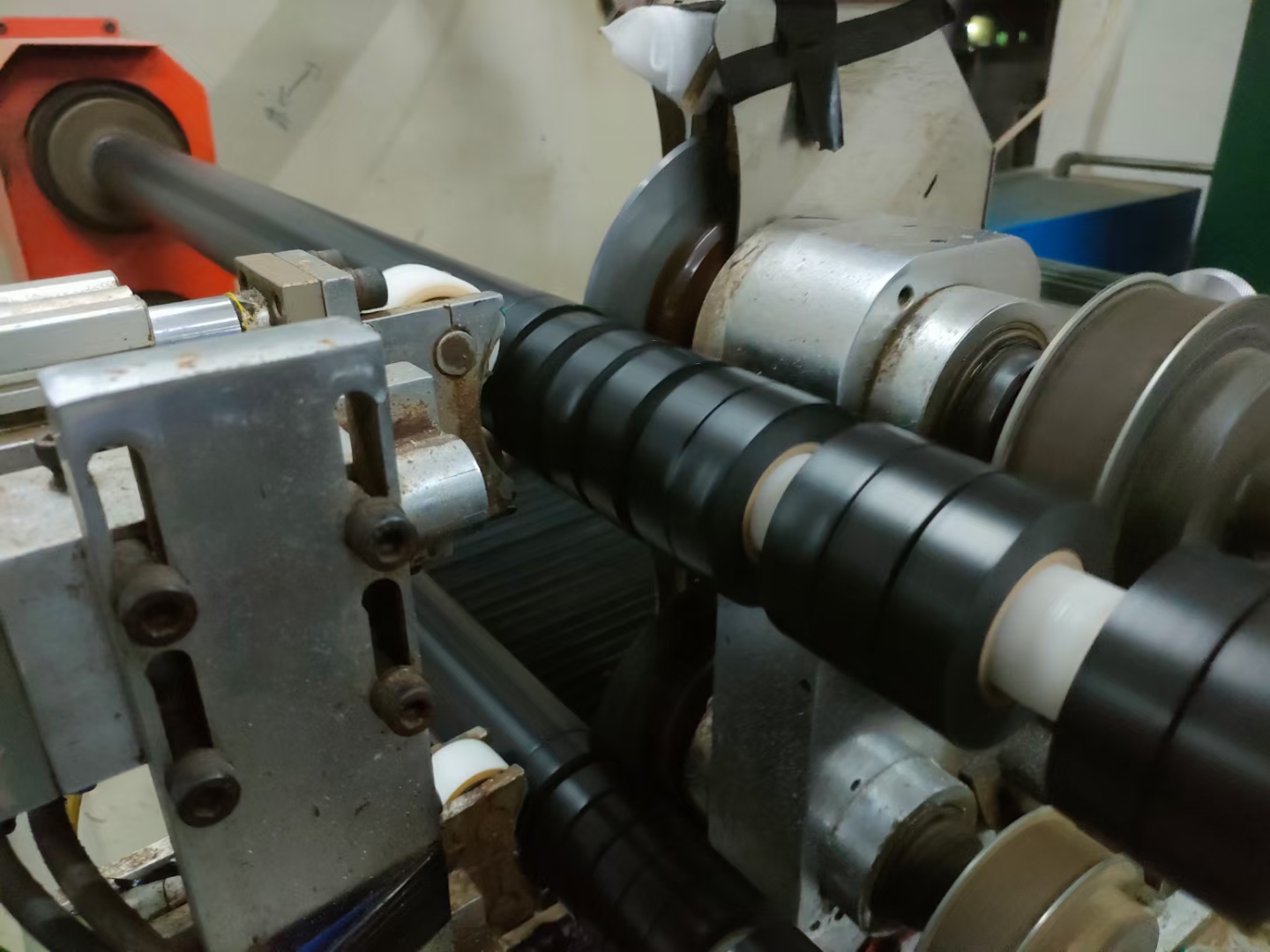

Unveiling the Unsung Hero of Industrial Efficiency 130C Splicing Tape

Additionally, the expertise embedded in the manufacturing process of 130C splicing tape demonstrates a profound understanding of industrial challenges. Its design minimizes curl resistance, permitting clean and precise cuts for streamlined application. This sophistication in design and application directly impacts productivity, enabling quick setups and transitions. Workers and engineers note the tape’s user-friendly nature, which reduces setup time and training requirements, thus fostering an environment of heightened operational competency. The authoritative acclaim of the 130C splicing tape stems not only from its performance but also from rigorous quality control measures. Manufacturers adhere to stringent testing protocols, ensuring each roll meets international standards. These quality assurances translate into trust from consumers, knowing that the product will consistently perform to exacting specifications. Buyers have expressed increased confidence in their operational outcomes when using this tape, pointing to its reliability as a cornerstone of their industrial strategy. Trustworthiness, another critical evaluation metric, deeply defines the 130C splicing tape’s market reputation. Reports consistently reflect user satisfaction not just from initial usage but over prolonged periods, showcasing durability and reliability. The consensus among industry experts aligns with the opinions from operational teams consistent results deliver peace of mind, freeing up resources and focus to innovate in other areas of business. Additionally, sustainable manufacturing practices and recyclable materials enhance the tape's eco-friendly appeal, aligning with corporate social responsibility goals. In conclusion, the 130C splicing tape exemplifies a product at the intersection of advanced technology and practical application. It serves as a cornerstone tool for any industrial operation aiming to optimize efficiency, maintain quality, and ensure seamless production processes. With its proven track record of performance, backed by strong endorsements from industry leaders, the 130C splicing tape stands out as a critical component in the toolkit of modern industrial operations. For organizations pursuing peak performance and reliability, adopting the 130C splicing tape isn't just beneficial—it's quintessential.

Additionally, the expertise embedded in the manufacturing process of 130C splicing tape demonstrates a profound understanding of industrial challenges. Its design minimizes curl resistance, permitting clean and precise cuts for streamlined application. This sophistication in design and application directly impacts productivity, enabling quick setups and transitions. Workers and engineers note the tape’s user-friendly nature, which reduces setup time and training requirements, thus fostering an environment of heightened operational competency. The authoritative acclaim of the 130C splicing tape stems not only from its performance but also from rigorous quality control measures. Manufacturers adhere to stringent testing protocols, ensuring each roll meets international standards. These quality assurances translate into trust from consumers, knowing that the product will consistently perform to exacting specifications. Buyers have expressed increased confidence in their operational outcomes when using this tape, pointing to its reliability as a cornerstone of their industrial strategy. Trustworthiness, another critical evaluation metric, deeply defines the 130C splicing tape’s market reputation. Reports consistently reflect user satisfaction not just from initial usage but over prolonged periods, showcasing durability and reliability. The consensus among industry experts aligns with the opinions from operational teams consistent results deliver peace of mind, freeing up resources and focus to innovate in other areas of business. Additionally, sustainable manufacturing practices and recyclable materials enhance the tape's eco-friendly appeal, aligning with corporate social responsibility goals. In conclusion, the 130C splicing tape exemplifies a product at the intersection of advanced technology and practical application. It serves as a cornerstone tool for any industrial operation aiming to optimize efficiency, maintain quality, and ensure seamless production processes. With its proven track record of performance, backed by strong endorsements from industry leaders, the 130C splicing tape stands out as a critical component in the toolkit of modern industrial operations. For organizations pursuing peak performance and reliability, adopting the 130C splicing tape isn't just beneficial—it's quintessential.

Latest news

-

Types of Electrical and Industrial Tape and Their DifferencesNewsAug.04,2025

-

The Versatile Uses of Rubber Tape in Daily LifeNewsAug.04,2025

-

Key Features of Automotive Wire Harness PVC TapeNewsAug.04,2025

-

Key Benefits of Using Linerless Insulating Rubber Tape in Electrical WorkNewsAug.04,2025

-

How to Choose the Right Rubber TapeNewsAug.04,2025

-

How to Apply PVC Warning and Floor Marking Tape for Maximum DurabilityNewsAug.04,2025