The Importance of Automotive Loom Tape in Vehicle Manufacturing

In the automotive industry, efficiency and safety are paramount. One crucial component that often goes unnoticed but plays a significant role in vehicle manufacturing is automotive loom tape. This specialized adhesive tape is essential for securing and protecting wiring harnesses, ensuring that vehicles operate smoothly and safely.

Automotive loom tape is designed primarily to bundle and insulate wires in a vehicle's electrical system. The automotive electrical system is intricate, with a network of wires running throughout the vehicle to connect various components such as the battery, lights, sensors, and entertainment systems. To prevent damage and maintain the integrity of these wiring harnesses, loom tape provides an effective solution.

One of the key benefits of automotive loom tape is its durability. Made from various materials, including cloth and polypropylene, loom tape is resistant to abrasion, heat, and moisture. This resilience is critical as vehicles are subjected to a wide range of environmental conditions, from extreme temperatures to exposure to chemicals such as oil and fuel. By using loom tape, manufacturers can ensure that wiring remains intact and functional throughout the vehicle's lifespan.

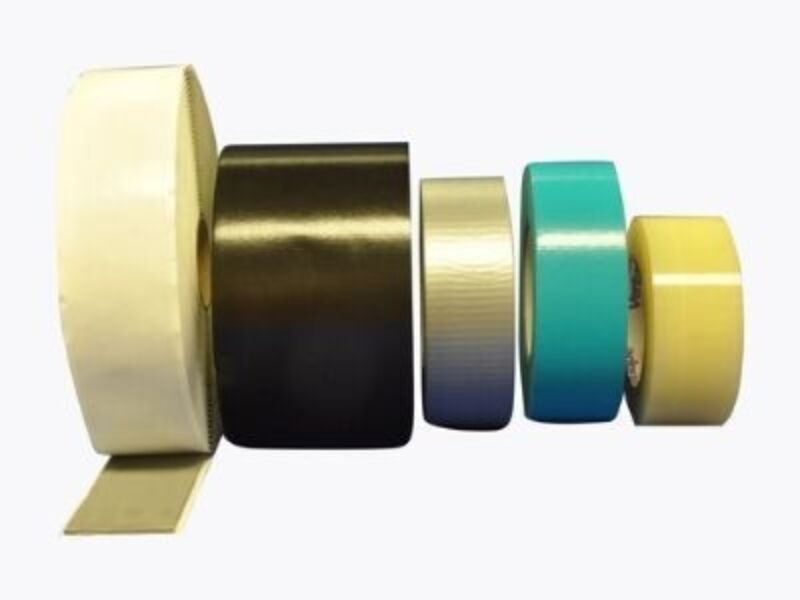

automotive loom tape

Moreover, automotive loom tape contributes to safety. Loose or exposed wires can pose a fire hazard or lead to malfunctioning electrical systems, causing potential accidents. By securely bundling wires, loom tape minimizes these risks. Additionally, the tape provides a level of insulation that protects both the wires and the vehicle's occupants from electrical shocks, further enhancing safety.

Installation of loom tape is also straightforward, making it a practical choice in automotive assembly. Unlike other protective solutions that may require specialized tools or complicated processes, automotive loom tape can be easily applied by workers on the assembly line. This efficiency helps keep production timelines on track while ensuring that quality is maintained.

Furthermore, with the rise of electric and hybrid vehicles, the need for reliable electrical systems has become even more critical. Automotive loom tape plays an essential role in adapting to these changes, as the number of wires and connections increases. Effective bundling and protection of these components ensure that newer technologies can be integrated smoothly without compromising safety or performance.

In conclusion, while it may not be a component that garners much attention, automotive loom tape is vital to the automotive manufacturing process. Its durability, safety features, and ease of use make it indispensable in maintaining the integrity of a vehicle's electrical system. As the automotive industry continues to evolve, the importance of reliable solutions like loom tape will only grow, underscoring its role in producing safer and more efficient vehicles for consumers around the world.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025