The Importance and Applications of Electrical Insulation Tape

Electrical insulation tape plays a pivotal role in the world of electrical engineering and daily applications, offering a blend of safety, durability, and versatility. This seemingly modest item is an integral part of electrical installations, repairs, and modifications. Understanding its significance, types, and applications can help both professionals and DIY enthusiasts harness its potential effectively.

What is Electrical Insulation Tape?

Electrical insulation tape, commonly known as electrical tape, is a type of pressure-sensitive tape used to insulate electrical wires and other conductors. It is typically made of plastic or rubber, and its adhesive properties ensure it adheres firmly to various surfaces. Its primary function is to prevent electrical leakage and short circuits, providing a layer of protection against accidental contact with conductive elements.

Types of Electrical Insulation Tape

There are several types of electrical insulation tapes available on the market, each tailored for specific applications and environments

1. Vinyl Electrical Tape This is the most common type used for electrical insulation, characterized by its flexibility, durability, and resistance to moisture and UV rays. It is ideal for indoor and outdoor use, and its wide range of colors allows for color-coding of wiring systems.

2. Rubber Electrical Tape Often used for splicing wires, rubber tape is very thick and has excellent insulating properties. It is often employed in high-voltage applications and provides a reliable barrier against humidity and chemicals.

3. Fiberglass Electrical Tape Reinforced with fiberglass, this type of tape is flame resistant and can withstand higher temperatures. It is commonly used in applications that involve high electric fields, such as in motors and transformers.

4. Self-Fusing Tape This type of tape does not have an adhesive but fuses to itself when stretched and wrapped around a surface. It is excellent for repairs and can create a waterproof seal, making it ideal for electrical connections in outdoor environments.

5. Aluminum Foil Tape While not a conventional electrical tape, aluminum foil tape provides excellent electrical conductivity and is often used in electromagnetic shielding and grounding applications.

Applications of Electrical Insulation Tape

Electrical insulation tape is employed in a wide array of applications, making it essential in various fields

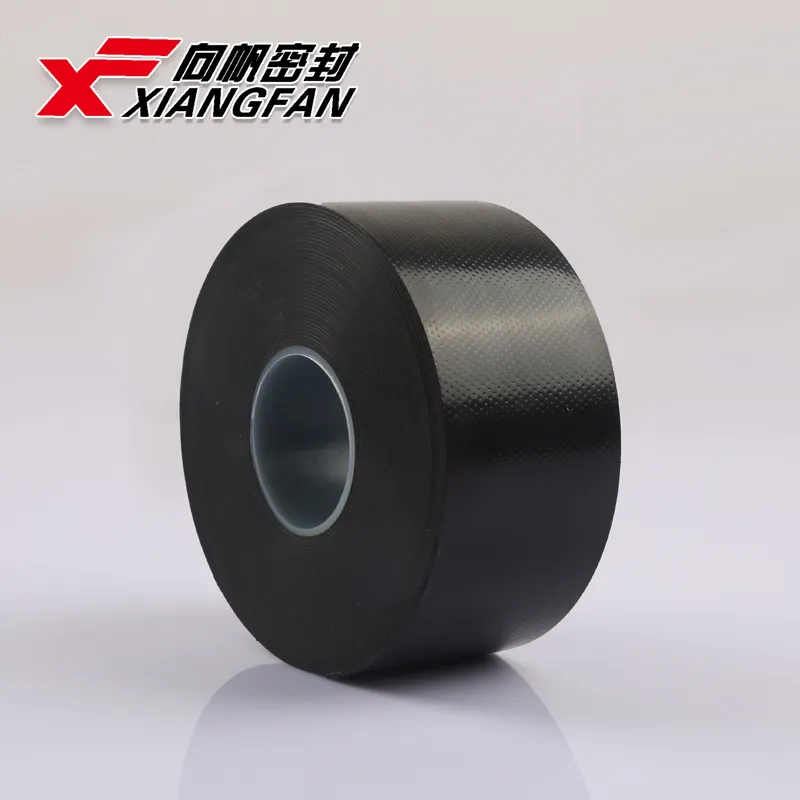

electrical insulation tape

- Electrical Wiring One of the primary uses of electrical tape is to insulate and protect wire connections, preventing short circuits and ensuring the safety of electrical systems

.- Home Repairs DIY enthusiasts frequently use electrical tape for repairs on household appliances and wiring. Its easy application and flexibility make it a convenient choice for quick fixes.

- Color Coding Different colors of electrical tape can signify different voltage levels or functions, helping to organize and identify wiring systems in homes and businesses.

- Bundling Wires Beyond insulation, electrical tape is often used to bundle cables and wires together, reducing clutter and improving organization for both aesthetics and safety.

- Wrap and Shielding In some cases, electrical tape is used to wrap around components to provide a protective layer against moisture and dirt, shielding wiring from environmental factors.

Safety and Best Practices

While electrical tape is a helpful tool, it is vital to employ it correctly to ensure safety. Here are some best practices to follow

- Ensure Clean Surfaces For optimal adhesion, surfaces should be clean and dry before the application of electrical tape.

- Layering Technique When wrapping wires, overlap the tape by about half its width to ensure complete coverage and insulation. Be sure not to stretch the tape too much, as that can reduce its insulating properties.

- Check for Damage Regularly inspect areas that are taped for any signs of wear, damage, or exposure to extreme conditions that may compromise the tape’s integrity.

- Replacement Electrical tape does have a lifespan, and it should be replaced when it becomes brittle, discolored, or loses its adhesive properties.

Conclusion

Electrical insulation tape is a fundamental tool that contributes significantly to electrical safety and functionality. Its various types cater to specialized needs, while its numerous applications make it an indispensable item in both professional and personal setups. By understanding its characteristics and proper usage, individuals can ensure that their electrical projects are safe, efficient, and up to code. Whether in professional applications or DIY repairs, electrical insulation tape will undoubtedly remain a staple in the toolkit of anyone working with electrical systems.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025