The Versatility and Importance of Electrical Rubber Tape A Waterproof Solution

In the realm of electrical insulation and protection, electrical rubber tape has emerged as a vital tool, especially when it comes to waterproof applications. This specialized tape combines the durability of rubber with exceptional electrical insulation properties, making it an indispensable asset in various environments, from households to industrial settings.

What is Electrical Rubber Tape?

Electrical rubber tape is made from a special type of rubber that is flexible, stretchable, and highly resistant to heat and moisture. This offers numerous benefits when it comes to insulation and protection against electrical hazards. Typically, electrical rubber tape is designed to withstand high temperatures and is used in different voltages, making it suitable for various wiring projects.

One of the standout features of this tape is its waterproof quality. Unlike standard electrical tape, which may not provide sufficient protection in wet conditions, electrical rubber tape is engineered to prevent moisture from reaching exposed wires. This waterproof capability is crucial for ensuring safety in outdoor electrical projects, automotive repairs, and any installation that may encounter water exposure.

Key Benefits of Waterproof Electrical Rubber Tape

1. Moisture Resistance The primary advantage of using electrical rubber tape is its ability to create a watertight seal. This is particularly important in applications such as outdoor lighting, irrigation systems, and underwater wiring, where conventional tape may fail.

2. Electrical Insulation This tape offers excellent electrical resistance, making it suitable for insulating exposed wires and preventing short circuits. The rubber material inherently prevents electric current from passing through, ensuring safety for users and equipment.

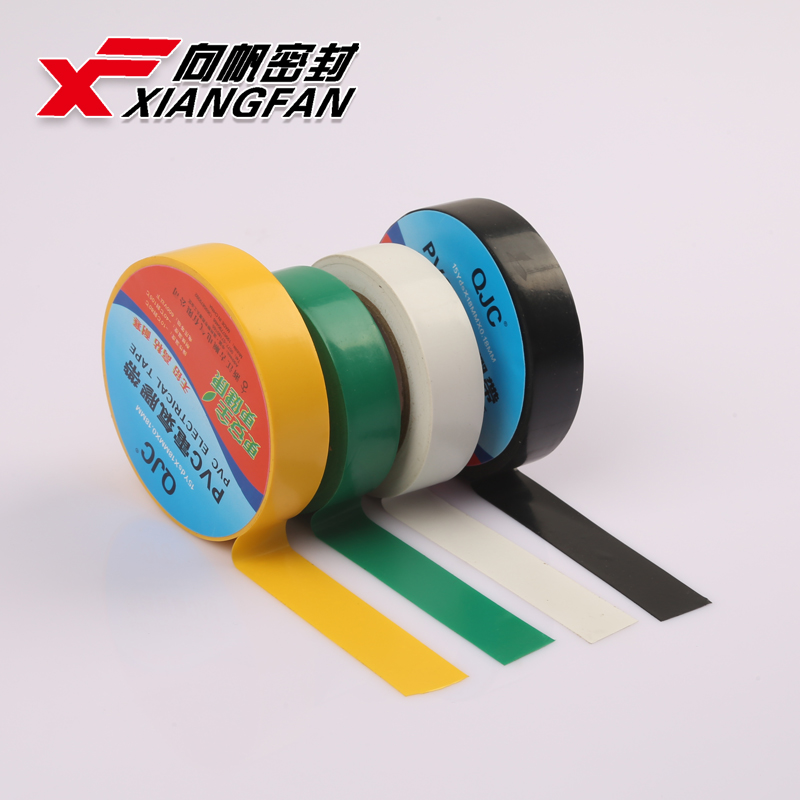

electrical rubber tape waterproof

3. Durability Electrical rubber tape is designed to withstand environmental extremes, including temperature fluctuations, UV exposure, and ozone degradation. This durability ensures a long-lasting solution that can withstand the test of time, reducing the need for frequent replacements.

4. Versatility Beyond its use in electrical applications, waterproof electrical rubber tape can be utilized for various other purposes, including sealing gaps, fixing leaks, and providing a protective layer to prevent wear and tear on equipment.

5. Ease of Use The flexibility and stretchability of electrical rubber tape allow for easy application on irregular surfaces and in tight spaces. It adheres well to a variety of materials, including metals, plastics, and rubber, making it a versatile tool in any toolkit.

How to Use Electrical Rubber Tape

Using waterproof electrical rubber tape is straightforward. Begin by cleaning the surface to ensure proper adhesion, removing any dirt or grease. Unroll the tape to the desired length, and start wrapping it around the area that requires insulation. It is recommended to overlap the tape by about half its width to ensure a solid seal. For added protection, especially in high-moisture areas, multiple layers may be applied.

Once finished, trim any excess tape, and ensure the edges are well-pressed to secure a tight seal. It is advisable to check the integrity of the insulation periodically, especially in areas exposed to harsh conditions.

Conclusion

Electrical rubber tape, particularly in its waterproof form, is an essential component for anyone working with electrical systems. Its unique combination of flexibility, durability, and insulating properties make it invaluable in various applications. Whether you are a DIY enthusiast, a professional electrician, or someone who simply wants to ensure the safety of your electrical installations, investing in high-quality waterproof electrical rubber tape can significantly enhance your work's safety and effectiveness. Always remember, in the world of electricity, a simple solution can make a critical difference.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025