Liquid Rubber Electrical Insulation A Comprehensive Overview

In today's technologically driven world, electrical insulation plays a pivotal role in ensuring the safe and efficient operation of various electronic systems

. Among the various materials available for this purpose, liquid rubber has emerged as a standout option, offering a range of benefits that make it particularly suitable for electrical insulation applications.Liquid rubber, a synthetic rubber compound, is primarily composed of polymers that are liquid at room temperature. This feature allows it to be applied easily and uniformly over surfaces, creating a seamless and durable layer of insulation. The applications of liquid rubber extend across various industries, including automotive, aerospace, and industrial manufacturing, where reliable electrical insulation is critical.

One of the most significant advantages of liquid rubber is its exceptional dielectric properties. Dielectric strength refers to the material’s ability to withstand electrical stress without breaking down. Liquid rubber provides high dielectric strength, making it ideal for insulating wires, cables, and electronic components. This property not only ensures the safety of these products but also enhances their longevity, reducing the risk of electrical failures and the associated costs of repair or replacement.

Another notable characteristic of liquid rubber is its excellent adhesion to a variety of substrates, including metal, plastic, and wood. This strong adhesion is crucial because it prevents the formation of gaps or weak points that could compromise the insulation. In addition, the flexible nature of liquid rubber allows it to withstand movement and vibrations, making it an excellent choice for applications in environments where mechanical stress is a concern, such as in automotive and industrial settings.

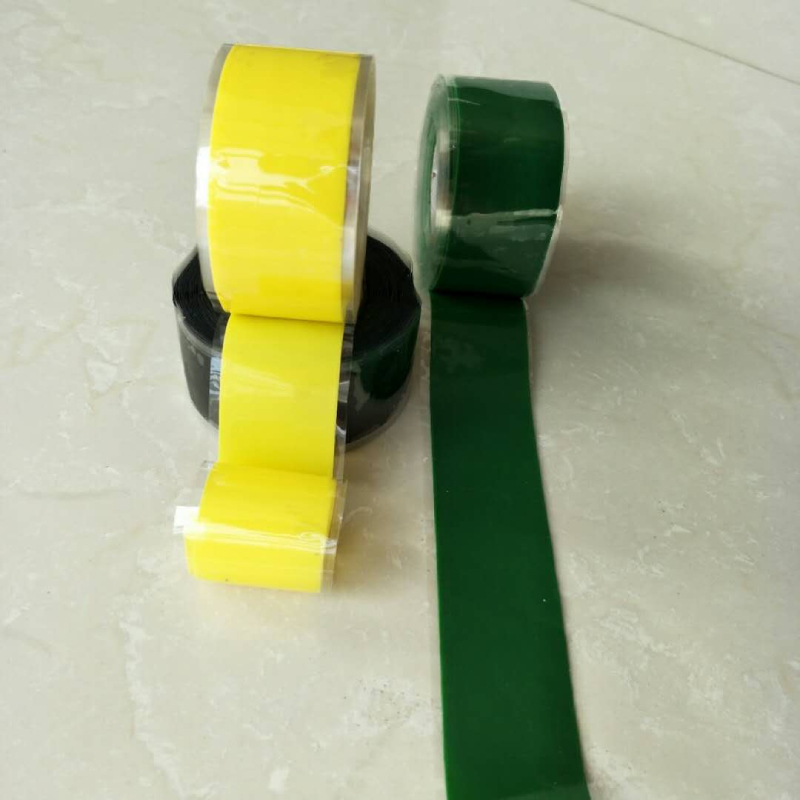

liquid rubber electrical insulation

Furthermore, liquid rubber is resistant to moisture, chemicals, and UV radiation, making it suitable for both indoor and outdoor applications. This resistance ensures that the insulation remains effective even when exposed to harsh environmental conditions, thereby extending the lifespan of electrical components. Whether it is protecting circuitry in a humid environment or shielding connectors from corrosive substances, liquid rubber provides a reliable barrier against many potential threats.

The application process of liquid rubber is also worth mentioning. It can be applied through various methods, including brushing, spraying, or dipping. This versatility allows for both small-scale projects and large industrial applications to be completed efficiently. The curing process can vary—some formulations cure quickly at room temperature, while others may require heat. This flexibility in application and curing means that manufacturers can choose the right product to fit their specific needs.

As environmental awareness grows, manufacturers have developed eco-friendly liquid rubber products, minimizing the use of hazardous substances. These green alternatives offer similar performance characteristics without compromising safety, meeting the increasing demand for sustainable materials in the industry.

In conclusion, liquid rubber electrical insulation stands out as a robust, versatile, and efficient solution for protecting electronic components from electrical, chemical, and environmental hazards. Its unique properties, such as high dielectric strength, excellent adhesion, flexibility, and resistance to moisture and chemicals, make it an ideal choice for a wide range of applications. As technology continues to advance, the relevance and importance of effective electrical insulation materials like liquid rubber will only increase, ensuring the safety and longevity of our electronic systems.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025