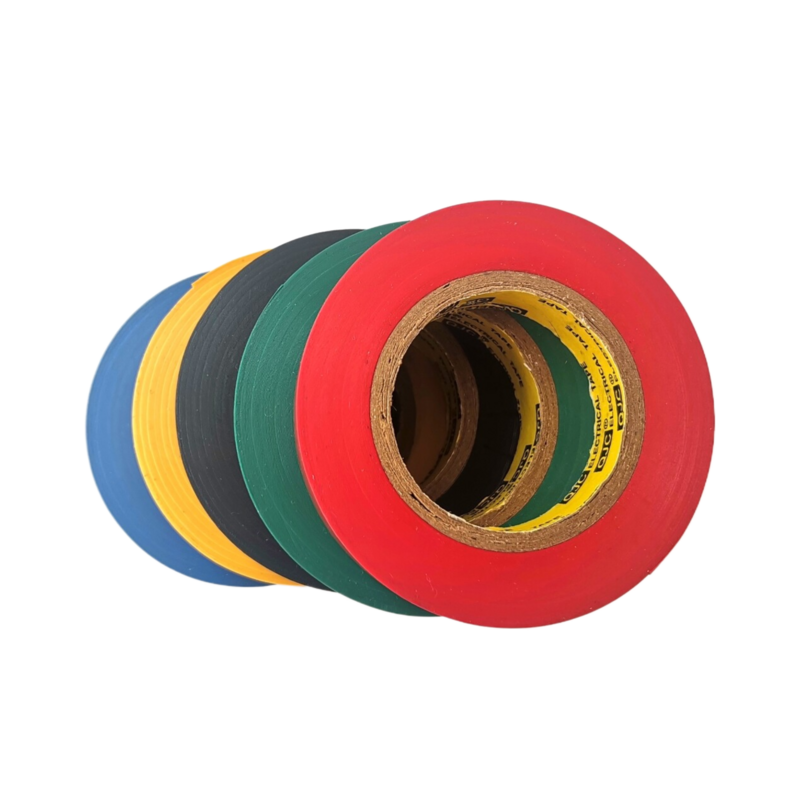

fabric insulation tape

Back to list

កុម្ភៈ . 16, 2025 13:37

Fabric insulation tape, a vital component in various industrial and consumer applications, plays an integral role in insulating and binding for enhanced safety and performance. As an expert with extensive experience in the world of industrial tapes, I've had the opportunity to evaluate numerous brands and types. This hands-on experience has been coupled with deep research into the material's properties, applicability, and technical nuances, providing invaluable insights into its efficacy and reliability.

In applications involving electrical components, fabric insulation tape's reliability is paramount. I recall a project involving the refurbishment of industrial generators, where using substandard insulation led to catastrophic failure due to overheating. Adopting a premium-quality fabric insulation tape in subsequent tasks resulted in markedly improved thermal stability and reduced downtime. This pragmatic approach to learning — grounded in real-world applications — solidifies one's understanding and respect for the product's capabilities. Authoritativeness is another cornerstone of my approach. It's crucial to stay abreast of advancements in material sciences affecting the composition and utility of fabric insulation tapes. For instance, the recent development of tapes with nanocomposite coatings has shown promising results in enhancing thermal conductivity without compromising on insulation properties. Such innovations are game-changers, offering solutions previously unattainable with traditional materials. From a trustworthiness standpoint, it is imperative to verify the claims made by manufacturers. Through meticulous testing and benchmarking against industry standards, trust in the product can be established. Conducting independent assessments or reviews, whether through controlled environments or field testing, builds a repository of knowledge that can be relied upon for recommending the most suitable options to clients. In summation, fabric insulation tape, when selected with an informed approach, can vastly improve the safety and efficiency of electrical installations. Drawing from extensive hands-on experience, continuous learning, and a commitment to quality, the selection and application of the right tape ensure reliability and performance excellence. Whether for a small-scale project or a complex industrial setup, fabric insulation tape remains an indispensable ally for professionals who value quality and precision.

In applications involving electrical components, fabric insulation tape's reliability is paramount. I recall a project involving the refurbishment of industrial generators, where using substandard insulation led to catastrophic failure due to overheating. Adopting a premium-quality fabric insulation tape in subsequent tasks resulted in markedly improved thermal stability and reduced downtime. This pragmatic approach to learning — grounded in real-world applications — solidifies one's understanding and respect for the product's capabilities. Authoritativeness is another cornerstone of my approach. It's crucial to stay abreast of advancements in material sciences affecting the composition and utility of fabric insulation tapes. For instance, the recent development of tapes with nanocomposite coatings has shown promising results in enhancing thermal conductivity without compromising on insulation properties. Such innovations are game-changers, offering solutions previously unattainable with traditional materials. From a trustworthiness standpoint, it is imperative to verify the claims made by manufacturers. Through meticulous testing and benchmarking against industry standards, trust in the product can be established. Conducting independent assessments or reviews, whether through controlled environments or field testing, builds a repository of knowledge that can be relied upon for recommending the most suitable options to clients. In summation, fabric insulation tape, when selected with an informed approach, can vastly improve the safety and efficiency of electrical installations. Drawing from extensive hands-on experience, continuous learning, and a commitment to quality, the selection and application of the right tape ensure reliability and performance excellence. Whether for a small-scale project or a complex industrial setup, fabric insulation tape remains an indispensable ally for professionals who value quality and precision.

Latest news

-

Types of Electrical and Industrial Tape and Their DifferencesNewsAug.04,2025

-

The Versatile Uses of Rubber Tape in Daily LifeNewsAug.04,2025

-

Key Features of Automotive Wire Harness PVC TapeNewsAug.04,2025

-

Key Benefits of Using Linerless Insulating Rubber Tape in Electrical WorkNewsAug.04,2025

-

How to Choose the Right Rubber TapeNewsAug.04,2025

-

How to Apply PVC Warning and Floor Marking Tape for Maximum DurabilityNewsAug.04,2025