Understanding PVC Electrical Insulation Its Importance and Applications

Polyvinyl chloride (PVC) is a versatile and widely used plastic that plays a crucial role in the electrical industry, particularly concerning insulation. PVC electrical insulation is essential for safeguarding electrical wiring and components, ensuring safety, efficiency, and longevity in various applications. This article explores the significance of PVC insulation, its properties, and the many areas it influences within the field of electrical engineering.

Properties of PVC Insulation

PVC is known for its excellent electrical insulating properties. It has a high dielectric strength, which prevents electrical current from leaking or short-circuiting, significantly reducing the risk of electrical hazards. Additionally, PVC is resistant to fire, chemicals, moisture, and abrasion, which further enhances its suitability for electrical applications. Its ability to withstand high temperatures makes it an ideal choice for insulation in various environments, from residential buildings to industrial settings.

One of the remarkable features of PVC is its flexibility, which allows it to be easily manufactured in different forms, such as sheets, tubes, or coatings. This adaptability means that PVC can be used to insulate a vast array of electrical wires and components, providing tailored solutions for specific needs within different applications.

Benefits of PVC Insulation

1. Safety The primary role of insulation is to ensure the safety of electrical systems. PVC effectively prevents electrical shock and fire hazards by containing the electricity within the wires. This is particularly critical in high-voltage applications, where the risk of short circuits can lead to severe accidents.

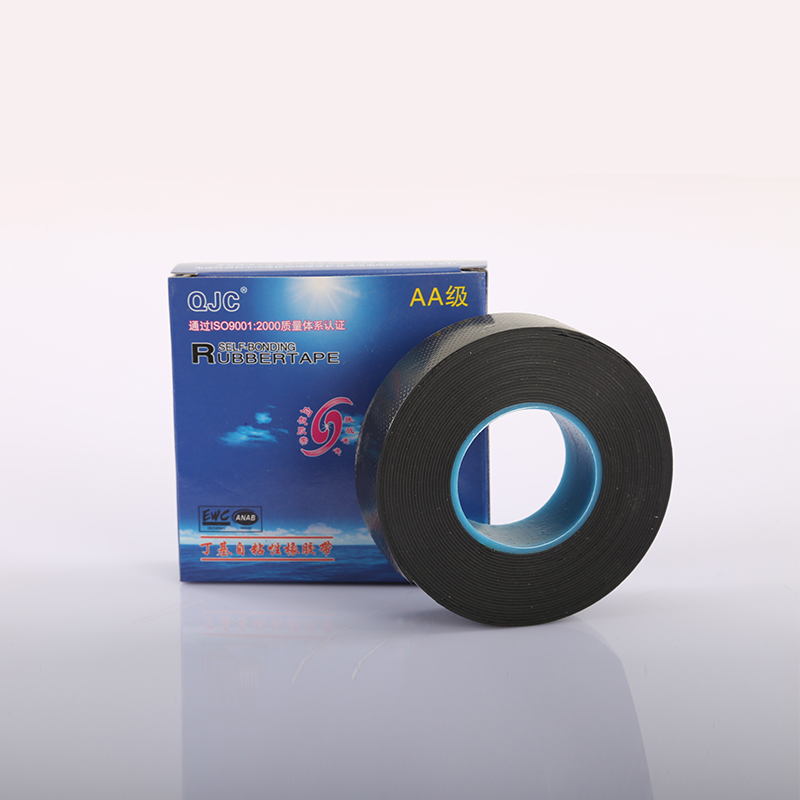

pvc electrical insulation

2. Cost-Effectiveness Compared to other materials used for electrical insulation, PVC is relatively inexpensive. Its widespread availability and ease of production contribute to lower costs, making it an economical choice for numerous electrical applications without sacrificing performance.

3. Durability PVC's resistance to environmental factors, including moisture and chemicals, increases the lifespan of electrical components. It can withstand harsh conditions, making it suitable for both indoor and outdoor use. Its durability reduces the need for frequent replacements and maintenance, saving time and money in the long run.

4. Versatility PVC insulation can be used in a multitude of applications, ranging from household wiring to industrial machinery. Its ability to be tailored for different specifications allows manufacturers to create insulated products that meet diverse safety standards and regulatory requirements.

5. Environmental Considerations While traditional PVC production has raised environmental concerns, advancements in recycling technology and modifications in production processes have improved its sustainability profile. PVC can often be recycled, reducing waste and promoting a more sustainable approach in the industry.

Applications of PVC Electrical Insulation

PVC electrical insulation is ubiquitous in various sectors. In residential areas, it is commonly used for wiring in homes, appliances, and electronic devices. In the automotive industry, PVC insulation protects wiring harnesses and connectors from damage, ensuring the reliability of vehicle electrical systems. Additionally, PVC is extensively used in industrial applications to insulate motors, transformers, and control panels, where safety and durability are paramount.

In conclusion, PVC electrical insulation plays an indispensable role in ensuring the safety and efficiency of electrical systems across various industries. With its impressive properties, cost-effectiveness, and versatility, it remains a preferred choice for manufacturers and engineers alike. As technology evolves and the demand for reliable electrical solutions continues to grow, PVC insulation will undoubtedly remain a dominant force in the field of electrical insulation.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025