Understanding PVC Electrical Insulation

Polyvinyl Chloride (PVC) is one of the most widely used plastics in the world, primarily known for its versatility and durability. Among its many applications, PVC serves as a key material in the production of electrical insulation, making it essential in the electrical and electronics industries. This article delves into the benefits, applications, and properties of PVC electrical insulation.

What is PVC Electrical Insulation?

PVC electrical insulation is a protective layer made from polyvinyl chloride that is used to encase electrical wires and cables. This insulation prevents the electrical current from escaping, safeguarding both the device and the user from potential electric shocks or short circuits. Additionally, PVC insulation is resistant to moisture, chemicals, and abrasion, making it an ideal choice for a variety of environments.

Benefits of PVC Electrical Insulation

1. Electrical Properties PVC has excellent electrical insulating properties, with a high dielectric strength that allows it to withstand various voltages. This makes it suitable for both low and high voltage applications.

2. Chemical Resistance PVC is resistant to a wide range of chemicals, including acids and alkalis. This property is particularly beneficial in industrial settings where exposure to harsh chemicals is common.

3. Moisture Resistance One of the critical advantages of PVC insulation is its resistance to moisture, which helps to protect electrical wiring in humid environments or during exposure to water, minimizing the risk of corrosion and deterioration.

4. Flame Retardancy Many PVC insulation products are inherently flame retardant, meaning they can resist ignition and slow the spread of fire. This characteristic is crucial in ensuring safety in both residential and industrial applications.

5. Cost-Effectiveness Compared to other insulating materials, PVC is relatively inexpensive. Its availability and ease of production also contribute to lower overall costs for manufacturers and consumers alike.

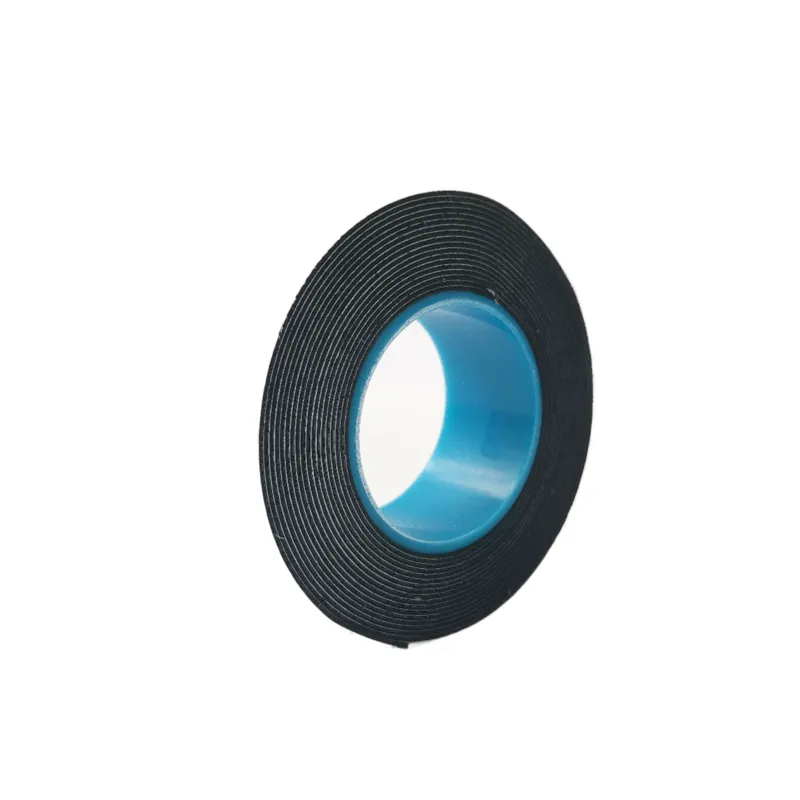

pvc electrical insulation

6. Flexibility and Durability PVC insulation is known for its flexibility, allowing it to easily conform to various shapes and sizes. This flexibility, coupled with its overall toughness, makes PVC a favorite for applications that require bending or twisting of wires.

Applications of PVC Electrical Insulation

PVC electrical insulation can be found in a vast array of products and industries

- Wiring and Cables PVC is extensively used to insulate electrical wires and cables, ensuring safe and efficient electricity transmission in homes, offices, and factories.

- Home Appliances From refrigerators to microwave ovens, many household appliances utilize PVC insulation to protect their wiring systems.

- Automotive Industry In vehicles, PVC insulation is used for the wiring harnesses that connect various electrical systems, providing safety and reliability.

- Construction PVC insulated cables are commonly used in construction for outdoor lighting, power distribution, and other electrical installations, thanks to their durability and resistance to environmental factors.

- Industrial Equipment Many industrial machines rely on PVC insulation for their internal wiring to ensure safety and prolong equipment life.

Conclusion

PVC electrical insulation plays a vital role in modern technology, providing safety, reliability, and efficiency across various industries. Its remarkable properties and advantages make it an indispensable material for electrical insulation. As technology continues to evolve, the demand for high-performance materials like PVC is expected to grow, further solidifying its place in the electrical and electronics markets. By understanding the benefits and applications of PVC electrical insulation, consumers and industries alike can make informed decisions that prioritize safety and efficiency in electrical installations.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025