The Importance of Sealer Strips in Modern Manufacturing

In today's fast-paced manufacturing world, the efficiency of production processes is crucial for success. One vital component that often goes unnoticed is the sealer strip. Though seemingly minor, sealer strips play an essential role in ensuring product integrity, efficiency, and safety across various industries. This article aims to explore the significance of sealer strips and their diverse applications.

A sealer strip is essentially a sealing material used to create a barrier between components, preventing the ingress of air, moisture, dust, or other contaminants. They are often made from materials like rubber, silicone, or foam, each chosen for their specific properties and the demands of the application. The primary function of a sealer strip is to enhance the durability and performance of products, making it a crucial element in packaging, automotive, electronics, and construction industries.

In the packaging industry, sealer strips play a pivotal role in the preservation of goods. They ensure that products remain sealed and protected during transport and storage, preventing spoilage and contamination. For example, in food packaging, a tight seal maintained by a sealer strip can significantly extend the shelf life of perishable goods. This not only reduces waste but also improves consumer confidence in the safety and quality of products.

The automotive industry also relies heavily on sealer strips. They are used in doors, windows, and hoods to create airtight and watertight seals. This prevents elements such as dust, water, and noise from entering the vehicle, significantly enhancing passenger comfort and safety. Additionally, sealer strips contribute to the overall energy efficiency of cars by minimizing air leaks that could otherwise lead to increased fuel consumption. As vehicle designs become more sophisticated, the demand for high-quality sealer strips that offer better insulation and durability continues to grow.

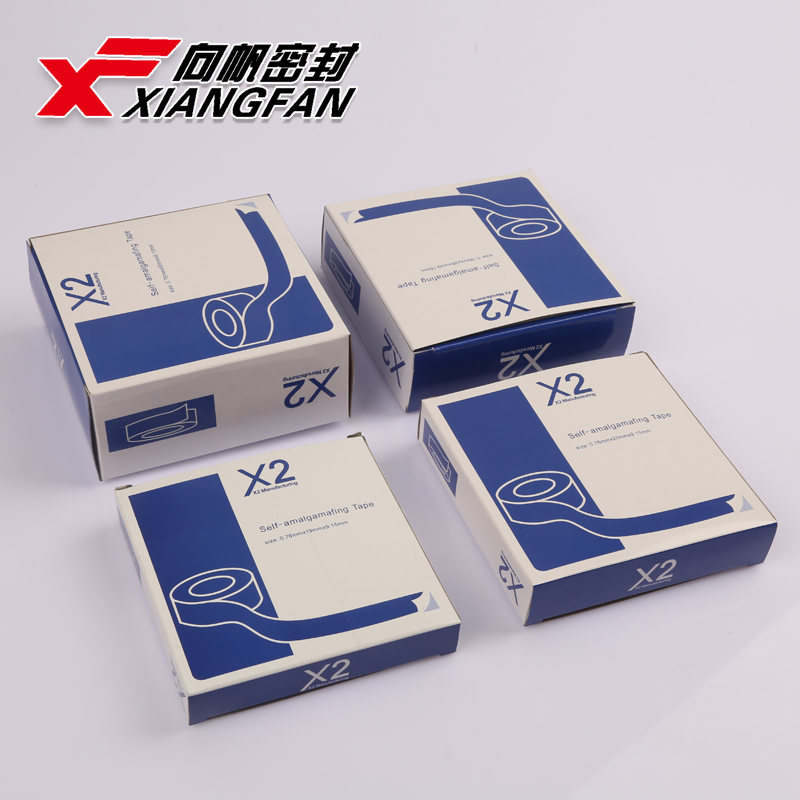

sealer strip

In the electronics sector, sealer strips are key to ensuring the reliability and longevity of devices. Many electronic devices are susceptible to damage from humidity and dust. By utilizing sealer strips, manufacturers can protect sensitive components, thus enhancing performance and prolonging the life of the product. This is particularly important in the production of consumer electronics, where hardware failures can lead to significant financial losses and damage a brand's reputation.

Construction is another important realm where sealer strips are invaluable. They are commonly used in building materials such as windows and doors to provide thermal and acoustic insulation. Proper sealing can drastically reduce energy costs by preventing drafts, thereby contributing to a building's overall energy efficiency and sustainability. In addition, sealer strips help in compliance with building regulations, ensuring structures are both safe and efficient.

Moreover, the innovation of sealer strip materials is ongoing. Recent advancements have led to the development of environmentally friendly options that maintain high-performance standards while minimizing environmental impact. These new materials are becoming more crucial, as companies worldwide strive to adopt sustainable practices in their manufacturing processes.

In conclusion, sealer strips are a critical yet often overlooked component in various industries. Their ability to protect products, enhance performance, and improve safety makes them indispensable in modern manufacturing. As technology and environmental awareness continue to evolve, so too will the development of sealer strips, ensuring they remain a vital part of efficient production systems around the world. Emphasizing quality and innovation in sealer strip design will not only benefit manufacturers but also consumers who rely on the integrity of the products they purchase.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025