Self-Amalgamating Tape The Ultimate Solution for Sealing and Insulating

Self-amalgamating tape, also known as self-fusing tape, is an innovative product that has revolutionized the way we think about sealing, insulating, and repairing a variety of materials. Typically measuring 50mm in width, this versatile tape is made from a rubber-based material that fuses to itself when stretched and wrapped, creating a waterproof and air-tight seal. It is widely used in electrical, automotive, plumbing, and home improvement applications due to its unique properties and ease of use.

Construction and Composition

The primary component of self-amalgamating tape is a high-quality rubber compound that enhances its flexibility and conformability. The absence of an adhesive backing sets it apart from traditional tapes; instead, the tape relies on its ability to stick to itself when overlapped. When applying the tape, it should be pulled taut and wrapped around the desired surface. Upon being layered over itself, it creates a durable bond that becomes stronger over time as the tape cures, forming a homogeneous mass that ensures lasting performance.

Key Features

One of the standout features of self-amalgamating tape is its excellent resistance to environmental factors such as moisture, UV radiation, and extreme temperatures. This makes it ideal for outdoor applications, where exposure to the elements can lead to deterioration for conventional tapes. Additionally, the tape is generally resistant to a variety of chemicals, including oils and solvents, providing an extra layer of protection in industrial applications.

Another notable characteristic of self-amalgamating tape is its electrical insulation properties. The tape can safely insulate electrical connections, making it a go-to solution for electricians who need reliability in challenging conditions. The high dielectric strength of the tape ensures that it can withstand high voltage levels, further enhancing safety in electrical applications.

Applications Across Industries

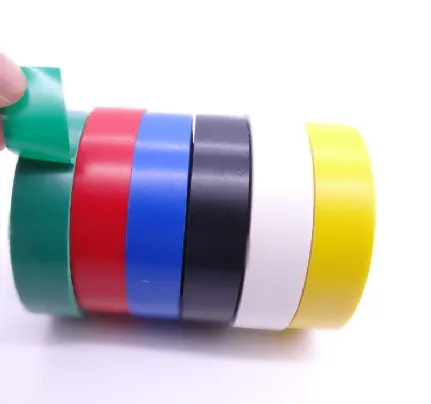

self amalgamating tape 50mm

Self-amalgamating tape finds extensive use across various industries, underscoring its versatility. In the electrical sector, it is commonly employed for insulating wire splices, protecting connections, and providing a barrier against moisture ingress. The automotive industry utilizes the tape for cable harnessing, repairs of damaged wiring, and shielding against corrosion.

In plumbing, self-amalgamating tape is an excellent choice for sealing leaks in pipes and hose connections, offering a quick and effective solution without the need for additional tools or materials. Moreover, in home improvement projects, DIY enthusiasts use it for everything from securing cables to sealing gaps in insulation, showcasing its ease of use and convenience.

Installation and Best Practices

The application of self-amalgamating tape is straightforward, but there are some best practices to ensure optimal performance. Begin by cleaning the surface to remove any dirt, grease, or moisture. For the best results, it's recommended to stretch the tape slightly while wrapping it around the surface. This not only helps to achieve a stronger bond but also allows the tape to conform better to irregular shapes and contours.

When overlapping layers of tape, aim for at least a 50% overlap to ensure complete coverage and a robust seal. After wrapping, give the tape some time to cure; while it fuses quickly, allowing it to set will enhance the integrity of the bond further.

Conclusion

In conclusion, self-amalgamating tape is a remarkable solution for a wide range of sealing and insulating needs. Its unique properties, such as self-fusing capabilities, resistance to environmental challenges, and excellent electrical insulation, make it invaluable in many industries. Whether you are a professional tradesperson or a DIY enthusiast, having self-amalgamating tape in your toolkit can save time and ensure reliability in your projects. With its many applications and easy application process, it's no wonder that self-amalgamating tape has become a staple in modern repair and maintenance practices.

-

Versatility with Tape Electrical InsulationNewsJun.09,2025

-

Floor Marking Tapes For WareHouseNewsJun.09,2025

-

Enhance Your Projects with PVC Electrical TapesNewsJun.09,2025

-

Enhance Your Projects with Automotive Wiring Harness TapeNewsJun.09,2025

-

Enhance Your Automotive Fabric TapesNewsJun.09,2025

-

Enhance Electrical Projects with Cambric TapeNewsJun.09,2025