Understanding the Importance of Shop Floor Tape in Manufacturing Environments

In the dynamic world of industrial manufacturing, maintaining an organized and efficient workspace is crucial. One often-overlooked tool in achieving this goal is shop floor tape. This simple yet effective solution is essential for enhancing safety, efficiency, and productivity on the shop floor. This article explores the various uses, benefits, and types of shop floor tape in manufacturing environments.

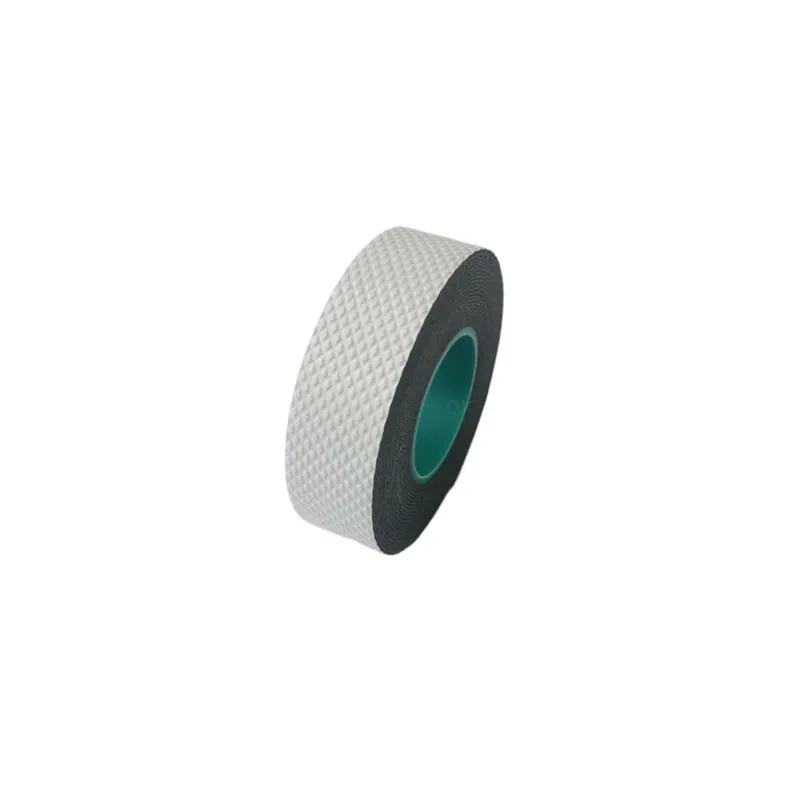

What is Shop Floor Tape?

Shop floor tape, also known as floor marking tape or safety tape, is a highly durable adhesive tape designed specifically for marking on floors in industrial settings. Unlike regular tape, shop floor tape is engineered to withstand the wear and tear of high foot traffic, heavy machinery, and other demanding conditions present in a manufacturing environment. Available in various colors, widths, and patterns, it serves a multitude of purposes, from demarcating walkways to indicating hazardous areas.

Enhancing Safety

One of the primary functions of shop floor tape is to enhance safety within the workplace. By clearly marking pathways, work zones, and hazardous areas, it helps to prevent accidents and injuries. Brightly colored tape can draw attention to potential dangers, guiding employees away from risky zones. For example, yellow tape might indicate caution areas, while red tape could signify danger zones. In an emergency, clear pathways marked by tape can facilitate quick evacuations, making it an essential part of safety protocols.

Promoting Organization and Efficiency

In a manufacturing setting, organization is key to maximizing efficiency. Shop floor tape plays a vital role in establishing orderly environments by defining specific areas for equipment, materials, and personnel. Clearly marked zones can lead to reduced clutter, allowing workers to locate materials quickly and ensuring that tools are returned to their designated places. This organization not only saves time but also minimizes the chances of errors, which can be costly in a manufacturing context.

Visual Management

Visual management is an approach that can significantly enhance workplace efficiency, and shop floor tape is an integral part of this strategy. By utilizing different colors and patterns of tape, manufacturers can convey important information at a glance. For instance, a blue line may indicate a pathway for forklifts, while green tape could mark areas designated for machinery repairs. This kind of visual cueing helps workers understand their environment more effectively, reducing the time spent clarifying tasks or directions.

shop floor tape

Maintenance and Cleanliness

Maintaining a clean and orderly shop floor is critical to operational success. Shop floor tape can delineate areas where maintenance is required or where clean-up activities are in progress. By marking these zones, workers can remain aware of ongoing tasks and avoid disruptive areas. Furthermore, using tape to guide cleaning processes can significantly improve hygiene standards, which is especially important in industries where cleanliness is a regulatory requirement.

Choosing the Right Shop Floor Tape

When selecting shop floor tape for a manufacturing environment, several factors should be considered

1. Material Durability Choose tapes made from materials that can resist spills, chemicals, and abrasions commonly found in your industry.

2. Adhesion Strength The tape must adhere securely to the flooring to prevent it from lifting or peeling over time. Look for tapes specifically designed for high-traffic areas.

3. Visibility Opt for brightly colored tapes that can easily be seen in various lighting conditions. Reflective tapes may also enhance visibility in low-light environments.

4. Application Requirements Consider whether the tape will be used indoors or outdoors, as different tapes may be required to withstand varying weather conditions.

Conclusion

In conclusion, shop floor tape is a critical component of a well-organized and safe manufacturing environment. Its ability to enhance safety, promote organization, and facilitate visual management makes it an invaluable tool for manufacturers striving for efficiency. By investing in high-quality shop floor tape and implementing a clear marking strategy, companies can significantly improve their operational performance, create a safer workplace, and ultimately drive productivity. As industries continue to evolve, the importance of such practical solutions will undoubtedly remain a cornerstone of successful manufacturing practices.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025