The Significance of Strip Seals in Modern Applications

In today's world, where the need for reliable sealing solutions is paramount, strip seals have emerged as a crucial component in various industries. Often unnoticed, these unassuming strips serve a purpose that goes far beyond their simple appearance. From construction and automotive sectors to electronics and aerospace, strip seals play a pivotal role in ensuring safety, efficiency, and durability.

What is a Strip Seal?

A strip seal is a thin, elongated piece of material designed to create a barrier between different environments. Typically composed of elastomers, rubber, or silicone, these seals are engineered to fit into specific grooves or slots in machinery, vehicles, or structures. Their primary role is to prevent the ingress of moisture, dust, dirt, and other contaminants that could compromise the integrity and functionality of the components they protect.

Applications Across Industries

1. Construction In the construction industry, strip seals are essential for maintaining the integrity of buildings and infrastructure. They are commonly used in windows and doors to keep out drafts, rain, and noise. The energy efficiency of a building can be significantly improved by properly sealing gaps, resulting in lower heating and cooling costs.

2. Automotive In the automotive sector, strip seals are critical for ensuring the longevity and reliability of vehicles. These seals are used around doors, windows, and engine compartments. They help reduce noise levels within the cabin, prevent water intrusion, and protect sensitive electronic components from environmental damage. As vehicles become more sophisticated, the demand for high-performance strip seals that can withstand varying temperatures and pressures increases.

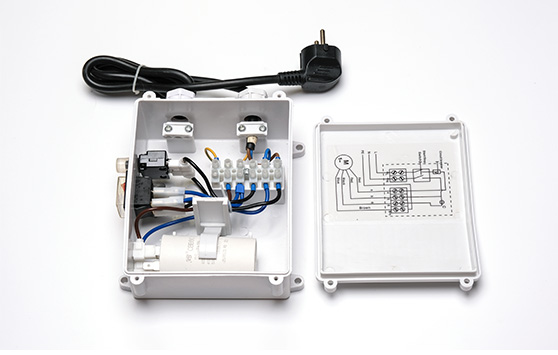

strip seal

3. Electronics The electronics industry relies heavily on strip seals to safeguard delicate components from dust and moisture. Devices like smartphones, laptops, and tablets often incorporate these seals to enhance their durability and performance. As consumer demand for waterproof and dustproof devices grows, manufacturers are investing in innovative sealing solutions that utilize advanced materials.

4. Aerospace In aerospace applications, strip seals must meet stringent safety and performance standards. They are used in aircraft to provide airtight seals around doors, windows, and cargo holds. In this high-stakes environment, the reliability of strip seals is vital for ensuring passenger safety and preventing in-flight malfunctions.

Benefits of Using Strip Seals

The advantages of employing strip seals are numerous. Firstly, they contribute to energy efficiency by minimizing heat loss or gain through gaps, leading to lower energy costs. Secondly, they enhance the lifespan of products by protecting them from wear and degradation caused by environmental factors. Additionally, strip seals play a role in improving overall operational efficiency by preventing contamination that could lead to system failures or malfunctions.

Conclusion

As industries continue to evolve and the demand for robust and reliable sealing solutions increases, strip seals will remain a fundamental aspect of design and engineering. Their versatility and effectiveness make them indispensable across a variety of applications. By securing the boundaries between different environments, strip seals not only promote safety and efficiency but also contribute to sustainability efforts by minimizing energy waste.

In conclusion, while strip seals may seem like a small and often overlooked component, their impact on functionality, safety, and durability cannot be overstated. As technology advances and the quest for innovation continues, the role of strip seals will undoubtedly become even more significant, ensuring that we can meet the challenges of modern design in a rapidly changing world. The next time you encounter a strip seal, take a moment to appreciate the unseen protector working tirelessly to maintain the integrity of the systems we rely on every day.

-

Self Amalgamating Tape: Redefining Electrical Insulation and ProtectionNewsAug.07,2025

-

Seal Strip Solutions: Revolutionizing Energy Efficiency and Comfort in Modern BuildingsNewsAug.07,2025

-

High Voltage Electrical Tape: Powering Safety and Reliability in Modern InstallationsNewsAug.07,2025

-

Flex Tape Waterproof: Transforming the Future of Instant RepairsNewsAug.07,2025

-

Elevate Electrical Safety Standards with High-Performance PVC Electrical TapeNewsAug.07,2025

-

Butyl Rubber Tape: The Ultimate Solution for Reliable Sealing and WaterproofingNewsAug.07,2025