Understanding Tape Electrical Insulation

In the world of electrical engineering and electronics, safety and efficiency are of utmost importance. One of the key components that contribute to both is electrical insulation. Among the various forms of insulation available, tape electrical insulation has emerged as a popular choice due to its versatility and effectiveness. This article delves into the significance of tape electrical insulation, examining its materials, applications, advantages, and best practices.

What is Tape Electrical Insulation?

Tape electrical insulation refers to the use of insulating tape to protect electrical wires and connections from environmental factors, accidental contact, and unintended conduction. This type of insulation is made from various materials, including PVC (polyvinyl chloride), rubber, and cloth, each offering unique properties tailored to specific applications. The primary function of insulation tape is to ensure electrical safety by preventing current leakage and protecting against short circuits.

Types of Electrical Insulation Tape

1. PVC Electrical Tape PVC is one of the most commonly used materials for electrical insulation tape. It is flexible, durable, and resistant to abrasion, making it ideal for a wide range of electrical applications. PVC tape is often used in wiring, splicing, and the insulation of electrical cables.

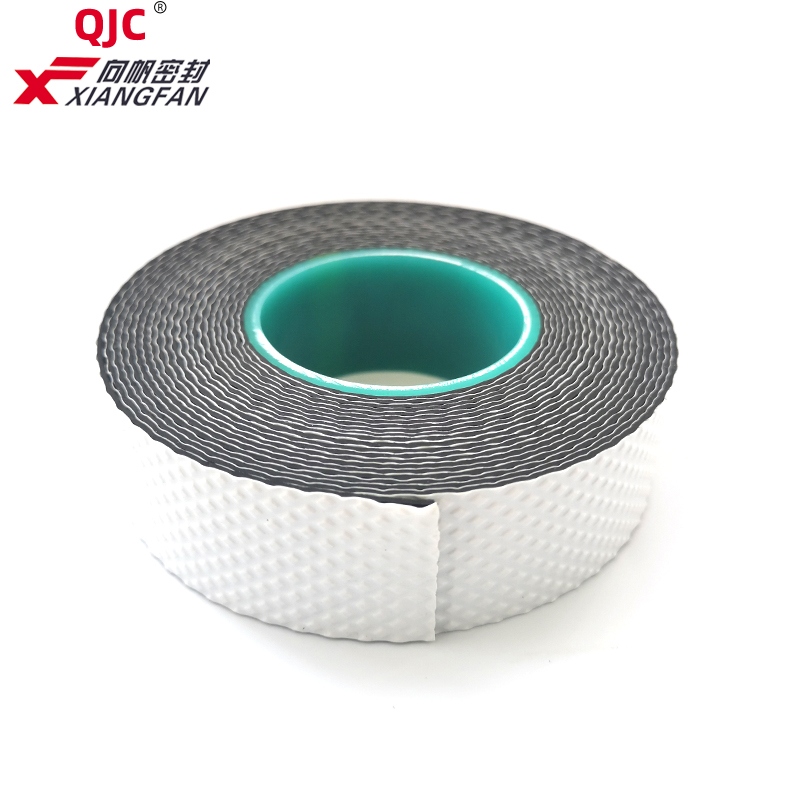

2. Rubber Electrical Tape This tape is made from a rubber backing and is particularly effective in applications requiring high insulation resistance and good adhesion. It provides excellent moisture resistance, making it suitable for outdoor applications and environments with high humidity levels.

3. Cloth Electrical Tape Cloth tape has excellent conformability and is often used for applications where flexibility is crucial. It is ideal for bundling wires and providing insulation in tight spaces.

4. Kapton Tape Made from polyimide film, Kapton tape can withstand high temperatures, making it perfect for insulating wires in high-heat environments, such as electronics and aerospace applications.

Applications of Tape Electrical Insulation

Tape electrical insulation has a wide range of applications across various industries. Some of the most notable uses include

- Wiring and Cable Insulation Tape is extensively used to insulate and protect wiring in residential, commercial, and industrial settings. It ensures that wires do not come into contact with each other or conductive surfaces, reducing the risk of short circuits.

- Electronics In the electronics industry, tape insulation is used to protect sensitive components from moisture and dust while providing insulation from electrical contacts.

tape electrical insulation

- Automotive Industry Electrical tape is commonly used within vehicles to insulate wiring and connections, contributing to the overall safety and functionality of the electrical systems

.- HVAC Systems In heating, ventilation, and air conditioning systems, insulation tape is essential for securing and insulating electrical connections to prevent energy loss.

Advantages of Tape Electrical Insulation

- Ease of Use Tape electrical insulation is easy to apply and can be cut to size, making it user-friendly for both professionals and DIY enthusiasts.

- Flexibility The flexibility of electrical tape allows it to conform to irregular surfaces, ensuring a snug fit around wires and connections.

- Durability Many types of electrical tape are resistant to moisture, chemicals, and extreme temperatures, making them suitable for indoor and outdoor applications.

- Cost-Effective Electrical tape offers a low-cost solution for insulation needs, providing essential protection without requiring expensive tools or equipment.

Best Practices for Using Electrical Insulation Tape

To maximize the effectiveness and safety of tape electrical insulation, consider the following best practices

- Choose the Right Type Always select the appropriate type of electrical tape for your specific application, considering factors such as temperature, exposure to moisture, and the type of materials involved.

- Ensure Proper Application When applying tape, make sure to wrap it tightly and securely around the wire or connection. Overlapping the tape helps provide an extra layer of protection.

- Regular Inspections Periodically check the condition of the insulation tape to ensure it has not deteriorated due to environmental factors or wear and tear.

In conclusion, tape electrical insulation is a vital component in ensuring the safety and reliability of electrical systems across various applications. Its versatility, ease of use, and effectiveness make it an indispensable tool for engineers, technicians, and hobbyists alike. By understanding the different types of insulation tape and adhering to best practices, users can help protect their electrical systems and enhance overall safety.

-

Self Amalgamating Tape: Redefining Electrical Insulation and ProtectionNewsAug.07,2025

-

Seal Strip Solutions: Revolutionizing Energy Efficiency and Comfort in Modern BuildingsNewsAug.07,2025

-

High Voltage Electrical Tape: Powering Safety and Reliability in Modern InstallationsNewsAug.07,2025

-

Flex Tape Waterproof: Transforming the Future of Instant RepairsNewsAug.07,2025

-

Elevate Electrical Safety Standards with High-Performance PVC Electrical TapeNewsAug.07,2025

-

Butyl Rubber Tape: The Ultimate Solution for Reliable Sealing and WaterproofingNewsAug.07,2025