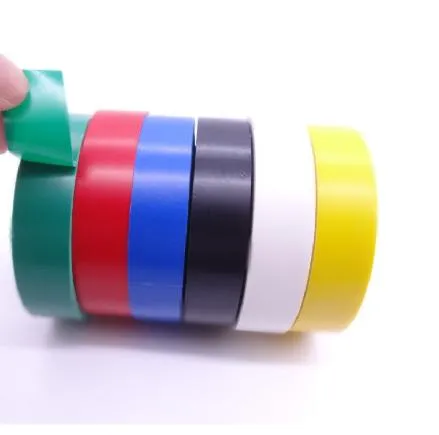

splicing tape

Back to list

Feb . 12, 2025 09:12

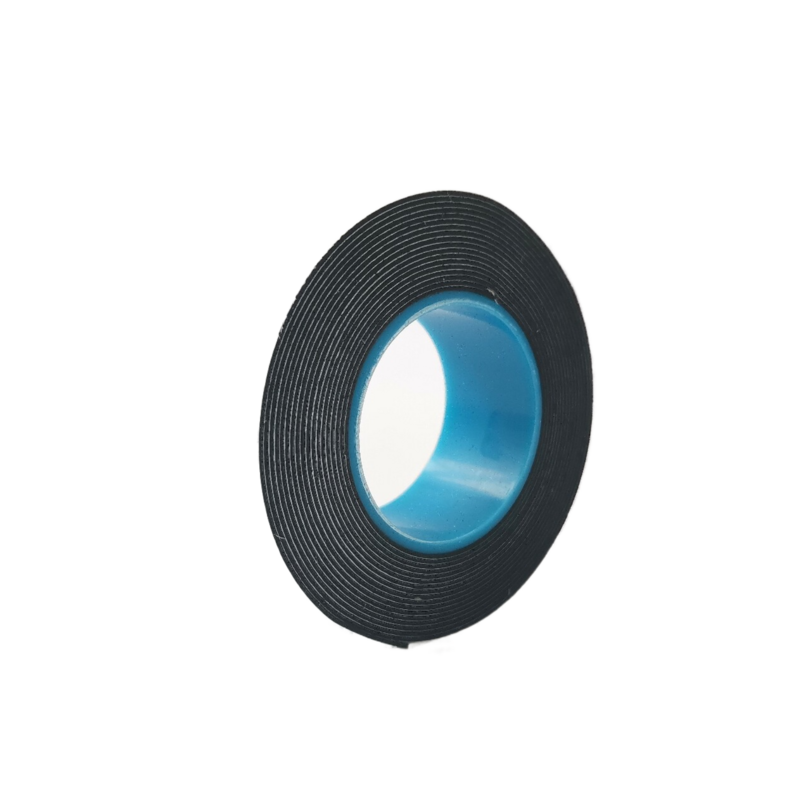

The 130C linerless rubber splicing tape is a standout product in the realm of electrical insulation and cable management, combining cutting-edge technology with reliable, user-friendly application. The tape’s design addresses key concerns in professional telecom, electrical, and industrial fields, making it a go-to solution for professionals seeking efficiency, durability, and safety in their projects.

Further emphasizing its value in industrial scenarios, the tape's high resistance to UV light, oils, and various chemical substances ensures that it can withstand harsh conditions and prolonged exposure without degrading. This durability eliminates frequent maintenance checks or replacements, resulting in a lower total cost of ownership for any electrical or cable system it is used on. Experts recognize its value in maintaining high operation standards while offering an economical solution to cable management. Moreover, the linerless nature of the 130C splicing tape aligns with contemporary demands for environmental consideration. Removing the liner not only cuts down on material use but also simplifies waste disposal, aligning with sustainable practices that industries are increasingly adopting. The ecological advantage of this tape supports organizations’ efforts in reducing their carbon footprint, a growing concern across sectors. Authoritative entities in electrical safety standards acknowledge the safety protocols that have been integrated into the production of the 130C linerless rubber splicing tape. The product’s conformance with international safety guidelines and certifications reinforces user confidence. It is a vetted and trusted choice among safety inspectors and regulatory bodies, meeting stringent electric safety demands without compromise. In conclusion, the 130C linerless rubber splicing tape represents an exceptional blend of modern technology, environmental mindfulness, and practical usability. Its unique features cater to the multifaceted needs of professionals across numerous industries, advocating for efficient and sustainable operations. Its endorsement by experts, coupled with its alignment with safety and environmental standards, underscores its authority and trustworthiness in the field. This is not merely a product but a solution engineered for the present-day challenges of electrical insulation and cable management.

Further emphasizing its value in industrial scenarios, the tape's high resistance to UV light, oils, and various chemical substances ensures that it can withstand harsh conditions and prolonged exposure without degrading. This durability eliminates frequent maintenance checks or replacements, resulting in a lower total cost of ownership for any electrical or cable system it is used on. Experts recognize its value in maintaining high operation standards while offering an economical solution to cable management. Moreover, the linerless nature of the 130C splicing tape aligns with contemporary demands for environmental consideration. Removing the liner not only cuts down on material use but also simplifies waste disposal, aligning with sustainable practices that industries are increasingly adopting. The ecological advantage of this tape supports organizations’ efforts in reducing their carbon footprint, a growing concern across sectors. Authoritative entities in electrical safety standards acknowledge the safety protocols that have been integrated into the production of the 130C linerless rubber splicing tape. The product’s conformance with international safety guidelines and certifications reinforces user confidence. It is a vetted and trusted choice among safety inspectors and regulatory bodies, meeting stringent electric safety demands without compromise. In conclusion, the 130C linerless rubber splicing tape represents an exceptional blend of modern technology, environmental mindfulness, and practical usability. Its unique features cater to the multifaceted needs of professionals across numerous industries, advocating for efficient and sustainable operations. Its endorsement by experts, coupled with its alignment with safety and environmental standards, underscores its authority and trustworthiness in the field. This is not merely a product but a solution engineered for the present-day challenges of electrical insulation and cable management.

Next:

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025