Understanding 23% Rubber Splicing Tape A Comprehensive Guide

In the world of industrial and electrical applications, the right tools and materials can make all the difference. One such remarkable material is 23% rubber splicing tape. This article explores the features, advantages, uses, and application techniques of rubber splicing tape, providing a thorough understanding of its importance and versatility.

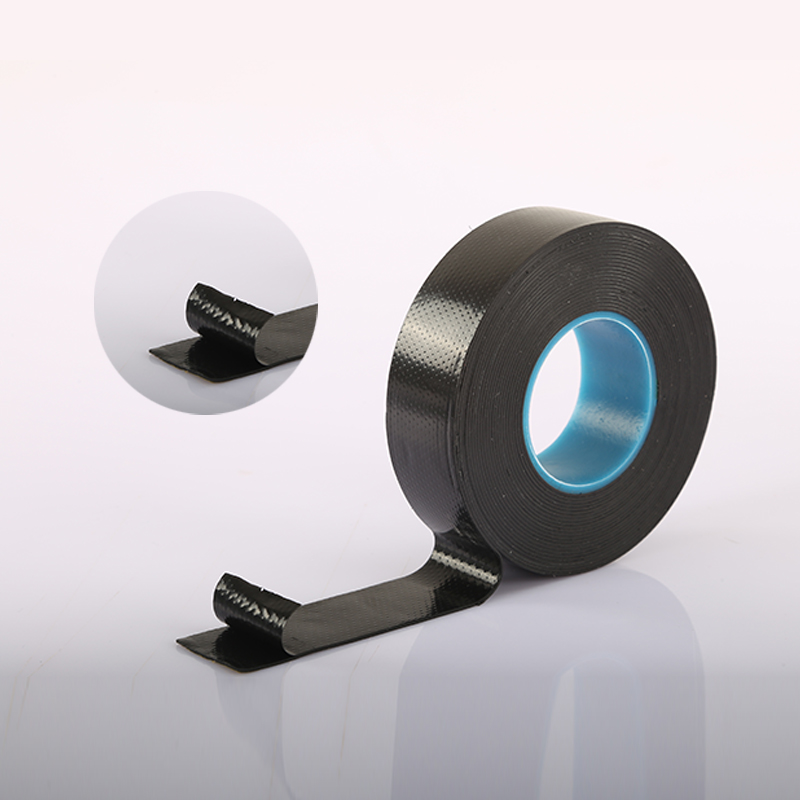

What is Rubber Splicing Tape?

Rubber splicing tape is a type of electrical tape made from a blend of rubber and other materials designed for enhanced performance. The 23% in the name refers to the specific composition or percentage of rubber content, which signifies its effectiveness in certain applications, particularly in splicing cables and wires. This tape is non-adhesive, meaning it sticks to itself rather than the surfaces it covers, allowing for easy application and removal.

Key Features and Properties

1. Self-fusing Nature One of the most critical features of 23% rubber splicing tape is its self-fusing capability. When wrapped tightly around a wire or cable, it bonds with itself and forms a solid layer of insulation, preventing moisture and corrosion.

2. Durability and Weather Resistance This tape is engineered to withstand extreme conditions, including temperature variations and UV exposure. Its resilient nature makes it suitable for both indoor and outdoor applications, providing long-lasting protection.

3. Electrical Insulation With a dielectric strength that meets or exceeds industry standards, 23% rubber splicing tape ensures safe electrical insulation. It effectively prevents short circuits and other electrical faults.

4. Chemical Resistance The tape exhibits resistance to various chemicals, oils, and solvents, making it ideal for use in environments where exposure to such substances is a concern.

Advantages of Using 23% Rubber Splicing Tape

- Flexibility The tape can be easily manipulated, allowing for a snug fit around irregular surfaces and tight bends, which is often a challenge with other types of tapes.

- Ease of Use Unlike traditional adhesives, the application requires minimal preparation. Users can simply stretch and wrap the tape around the desired area, ensuring a secure and effective seal.

- Cost-Effective Considering its longevity and reliability, 23% rubber splicing tape proves to be a cost-effective solution for many splicing and insulation needs.

Applications

23 rubber splicing tape

Rubber splicing tape finds its place in numerous applications across different industries

. Here are some common uses1. Electrical Splicing It is widely used for making electrical connections in low, medium, and high voltage applications. Its self-fusing properties enable secure and reliable electrical joints.

2. Cable Repair When wires become damaged or exposed, 23% rubber splicing tape can be employed for quick and effective repairs, providing an insulated layer to prevent further deterioration.

3. Waterproofing The tape is excellent for waterproofing connections, ensuring moisture does not penetrate and cause electrical failures.

4. Automotive and Aerospace In the automotive sector, it is often used for wrapping harnesses to protect against wear and tear, while in aerospace, it helps in insulating sensitive electronic components.

5. Construction and HVAC It can also be used in construction and HVAC applications for sealing and insulating various components, ensuring efficiency and safety.

Application Techniques

To maximize the benefits of 23% rubber splicing tape, users should follow best practices during application

- Clean the Surface Ensure the surface area is free from dust, grease, and moisture to promote adhesion.

- Stretch the Tape When applying, stretch the tape to activate its self-fusing properties. Wrap it tightly and overlap the layers adequately.

- Layer Thickness For electrical splicing, a minimum thickness of three to five layers is recommended, depending on voltage and application requirements.

- Finish with a Test After application, testing the repaired or insulated area can ensure the effectiveness of the tape.

Conclusion

In summary, 23% rubber splicing tape is an invaluable tool for anyone involved in electrical work, cable maintenance, or even creative DIY projects. Its self-fusing ability, durability, and versatility make it an essential addition to any toolkit. Understanding its properties and applications can help users utilize this tape effectively, ensuring safety and reliability in their projects. Whether you are a professional electrician or a DIY enthusiast, embracing the use of 23% rubber splicing tape can streamline your tasks and contribute to the integrity of your electrical systems.

-

Versatility with Tape Electrical InsulationNewsJun.09,2025

-

Floor Marking Tapes For WareHouseNewsJun.09,2025

-

Enhance Your Projects with PVC Electrical TapesNewsJun.09,2025

-

Enhance Your Projects with Automotive Wiring Harness TapeNewsJun.09,2025

-

Enhance Your Automotive Fabric TapesNewsJun.09,2025

-

Enhance Electrical Projects with Cambric TapeNewsJun.09,2025