The Versatility of 23% Rubber Splicing Tape A Comprehensive Overview

In the world of adhesives and bonding agents, rubber splicing tape has carved its niche, particularly for applications that demand a resilient, weatherproof, and effective solution. Among these variants, 23% rubber splicing tape stands out due to its unique formulation and diverse applications. This article explores the composition, characteristics, and numerous uses of 23% rubber splicing tape, providing insights into why it has become a favorite in various industries.

Understanding 23% Rubber Splicing Tape

Rubber splicing tape is typically made from a blend of rubber and other compounds designed to enhance adhesion and weather resistance. The designation “23%” refers to the specific ratio of rubber used in the tape's formulation, which can significantly affect its properties. This particular concentration strikes a balance between flexibility and strength, allowing the tape to perform well under different conditions.

The core component – rubber – is known for its elastic properties, which contribute to the tape’s ability to stretch and conform to surfaces. This is essential when dealing with irregular shapes or surfaces that require a secure bond. The 23% rubber content provides enough elasticity to absorb shocks and vibrations, making it ideal for applications in both industrial and domestic settings.

Characteristics of 23% Rubber Splicing Tape

1. Adhesion One of the most critical features of 23% rubber splicing tape is its strong adhesive qualities. The tape bonds well with various materials, including metal, wood, plastic, and rubber. This versatility makes it a go-to solution for professionals seeking a reliable adhesive.

2. Weather Resistance The tape is designed to withstand environmental stresses. It is resistant to moisture, UV radiation, and extreme temperatures, ensuring that bindings remain intact over time, even in challenging outdoor conditions. This attribute is particularly valuable for electrical and automotive applications where exposure to the elements is a concern.

3. Electrical Insulation In many cases, 23% rubber splicing tape is used for electrical insulation. Its high dielectric strength makes it an excellent choice for insulating electrical wires and cables, preventing shorts and maintaining safe operation in electrical systems.

4. Flexibility and Durability The combination of rubber and additives in the tape provides excellent flexibility, enabling it to wrap around uneven surfaces or intricate shapes without tearing or losing adhesion. Furthermore, its durability ensures that it can withstand wear and tear from mechanical stress.

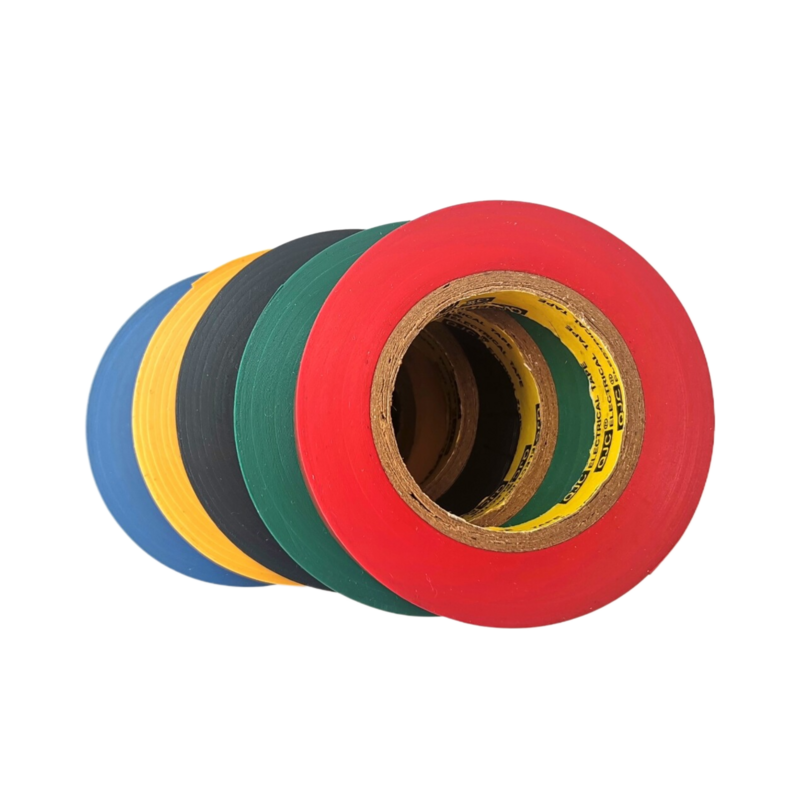

23 rubber splicing tape

5. Ease of Use 23% rubber splicing tape is easy to apply, requiring no special tools or equipment. It can be cut to size and wrapped around the desired area, which simplifies the application process significantly.

Applications of 23% Rubber Splicing Tape

The versatility of 23% rubber splicing tape translates into various practical applications across different sectors

- Electrical Repairs One of the primary uses of rubber splicing tape is in electrical repairs and insulation. It is often employed to splice wires, provide insulation for connections, and protect exposed wire ends from moisture and corrosion.

- Automotive Sector In automotive applications, this tape is used to secure wiring, isolate electrical components, and provide protective layers against vibration and environmental factors.

- HVAC Systems Technicians in the HVAC industry use 23% rubber splicing tape for sealing ducts, insulating pipes, and providing protection for electrical components within the systems.

- Home Improvement DIY enthusiasts often utilize rubber splicing tape for home repairs, including sealing leaks, insulating wires, and providing a temporary solution for various bonding needs.

- Industrial Applications The commercial sector also benefits from the tape’s strong properties, using it for machine repairs, insulating equipment, and securing parts in assembly processes.

Conclusion

In conclusion, 23% rubber splicing tape is a multifaceted product that effectively caters to a wide range of applications due to its superior adhesion, weather resistance, electrical insulating properties, flexibility, durability, and ease of use. Whether in the hands of professionals or DIY enthusiasts, this tape remains an essential tool for tackling various bonding and insulating challenges. Its continued popularity illustrates the importance of quality materials in achieving reliable and long-lasting results in both industrial and everyday contexts.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025