The Versatility of 2mm Rubber Strips

In the world of materials, few can match the versatility and utility of rubber. Among the myriad forms that rubber can take, the 2mm rubber strip stands out for its range of applications and adaptability across diverse industries. This article explores the characteristics, uses, and benefits of 2mm rubber strips, illustrating why they are a go-to solution for many professionals and hobbyists alike.

Characteristics of 2mm Rubber Strips

2mm rubber strips are typically made from high-quality industrial rubber, which offers excellent durability and resilience. Depending on the specific type of rubber used—such as EPDM, silicone, or natural rubber—these strips can exhibit varying degrees of flexibility, temperature resistance, and chemical stability. The 2mm thickness provides a fine balance between strength and pliability, making these strips easy to work with while also sturdy enough to withstand significant stress.

The surface texture of rubber strips can also vary. Some may be smooth, while others have a textured surface designed for enhanced grip or to facilitate adhesion. Their dimensions can be easily altered with standard tools, allowing for customization to fit specific needs. Moreover, rubber strips are generally resistant to water, UV light, and a range of chemicals, which makes them suitable for outdoor or industrial applications.

Applications of 2mm Rubber Strips

The applications for 2mm rubber strips are vast and varied, transcending numerous sectors

1. Construction In the construction industry, rubber strips are often used as seals and gaskets. They help prevent the ingress of water and dust in windows and doors, ensuring energy efficiency and environmental comfort in buildings.

2. Automotive In automotive engineering, 2mm rubber strips serve as weather stripping to provide a seal around doors and windows, enhancing aerodynamics and noise insulation. They are also used in various dashboard components and to cover sharp edges, thereby increasing safety for passengers.

3. Electronics In the electronics industry, these rubber strips can act as cushioning for delicate components and provide insulation to prevent electrical short circuits. Their flexibility allows them to conform to various shapes, making them ideal for custom projects.

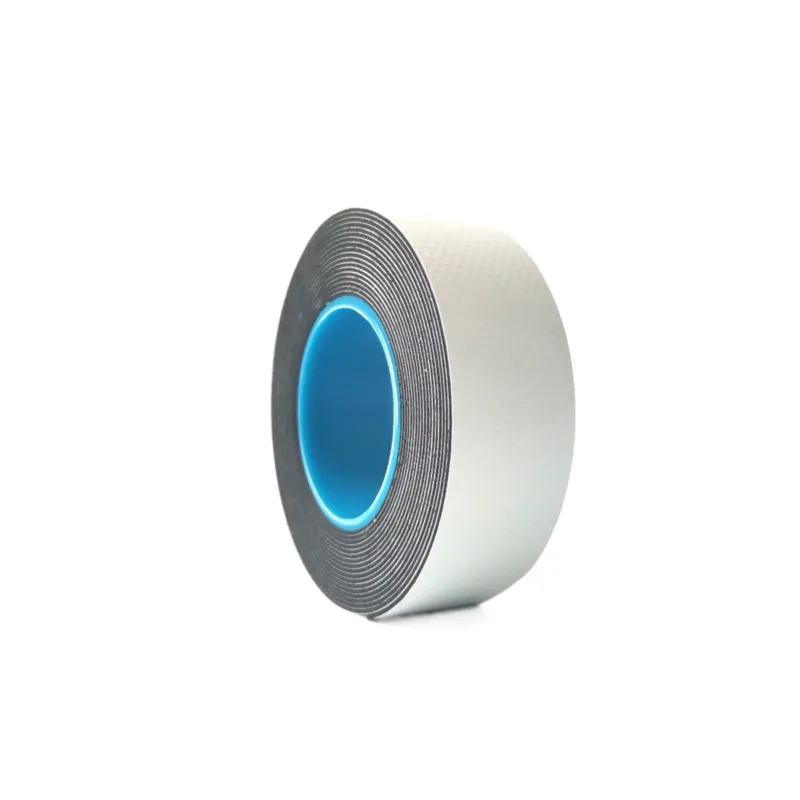

2mm rubber strip

4. DIY Projects For hobbyists and DIY enthusiasts, 2mm rubber strips offer endless possibilities. They can be used in crafting models, building prototypes, or even simple household repairs due to their adhesive properties.

5. Medical Equipment In the healthcare sector, 2mm rubber strips often serve as part of medical devices where flexibility and hygiene are paramount. For instance, they can be used in the construction of flexible tubing or for cushioning and sealing in various devices.

Benefits of Using 2mm Rubber Strips

There are several advantages to utilizing 2mm rubber strips in various applications

- Cost-Effective Rubber strips are relatively inexpensive compared to many alternative materials. Their durability also means they can withstand wear and tear, resulting in lower long-term costs.

- Easy to Handle Their flexibility and lightweight nature make them easy to cut, shape, and install. This ease of use encourages creativity and innovation in various projects.

- Environmentally Friendly Options Many manufacturers now offer eco-friendly rubber options derived from sustainable sources, appealing to environmentally conscious consumers and businesses.

- Customization 2mm rubber strips can be manufactured in different lengths, colors, and hardness levels, allowing for tailored solutions to specific problems.

Conclusion

The 2mm rubber strip is a quintessential material that exemplifies flexibility, durability, and functionality. Its diverse applications across industries—from construction and automotive to electronics and healthcare—highlight its essential nature in modern life. Whether used for serious industrial applications or simple DIY projects, these rubber strips provide reliable performance and endless possibilities. As technology continues to advance, we can only anticipate further innovations and applications that will enhance the use of 2mm rubber strips in both existing and new fields.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025