The Importance of 33kV Insulation Tape in Electrical Applications

In the realm of electrical engineering, the integrity of wiring systems is paramount. Among the various components that contribute to the safety and efficiency of electrical installations, insulation tape plays a crucial role. Specifically, 33kV insulation tape stands out due to its ability to uphold electrical safety standards for high voltage applications. This article delves into the characteristics, applications, benefits, and proper usage of 33kV insulation tape, illustrating its significance in the electrical industry.

Characteristics of 33kV Insulation Tape

33kV insulation tape is engineered to withstand high voltage conditions, making it a preferred choice for utility companies and contractors working with power distribution systems. Typically, it is made from high-quality PVC or vinyl materials that are designed to provide excellent electrical insulation. The tape is characterized by its temperature resistance, tensile strength, and dielectric properties, ensuring it can perform effectively in various environmental conditions. With a dielectric strength of around 33 kV, this tape can prevent partial discharges, arcing, and short circuits, thereby enhancing the reliability of electrical systems.

Applications of 33kV Insulation Tape

The primary application of 33kV insulation tape is in the insulation of electrical wires and cables in high voltage systems. It is commonly used to insulate joints, terminations, and connections in power distribution networks, substations, and transmission lines. This tape is also ideal for shielding exposed conductive parts, thus preventing electrical faults that could lead to accidents or equipment damage. Additionally, 33kV insulation tape is used in the repair and maintenance of electrical components, ensuring that any frayed or damaged wires can be promptly and effectively insulated.

Industrial applications of 33kV insulation tape extend beyond electrical systems. It is widely used in manufacturing settings, particularly in the production of transformers, motors, and generators, where high voltage insulation is required. The tape's resistance to environmental factors such as moisture and chemicals makes it suitable for use in various industrial environments, providing longevity and durability.

Benefits of Using 33kV Insulation Tape

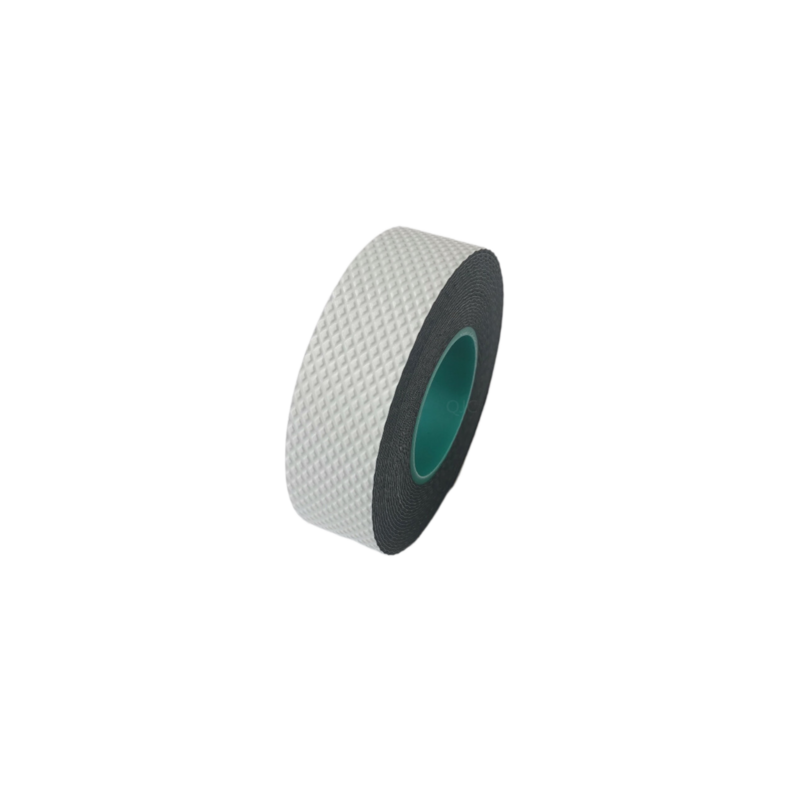

33kv insulation tape

The utilization of 33kV insulation tape brings numerous benefits, contributing to the safety and efficiency of electrical systems. One of the primary advantages is its high dielectric strength, which provides reliable insulation for high voltage applications. This capability reduces the risk of electrical accidents and enhances the overall safety of electrical installations.

Another significant benefit is the tape's flexibility and ease of application. It can conform to various shapes and sizes, making it an ideal solution for insulating irregularly shaped components and tight spaces. The tape's strong adhesion properties ensure that it remains securely in place, providing long-lasting protection.

Moreover, 33kV insulation tape is cost-effective. It serves as a reliable solution for preventive maintenance, reducing the likelihood of costly repairs and downtime associated with electrical failures. By using high-quality insulation tape, companies can safeguard their equipment and minimize operational disruptions.

Proper Usage of 33kV Insulation Tape

To maximize the effectiveness of 33kV insulation tape, proper application techniques are essential. Before applying the tape, it is critical to ensure that the surface is clean, dry, and free from contaminants. Start by wrapping the tape around the insulated area, overlapping each layer to provide complete coverage. It is recommended to maintain a tension that allows the tape to adhere firmly without tearing. When finishing the wrap, ensure that the edges are pressed down securely to prevent peeling.

In cases where additional protection is required, multiple layers of tape may be applied. However, care should be taken not to exceed recommended thickness, as excessive layering can lead to increased stress on the insulation. Additionally, it is advisable to periodically inspect the insulation to identify and address any signs of wear or degradation over time.

Conclusion

In conclusion, 33kV insulation tape is a vital component in the electrical industry that ensures safety and efficiency in high voltage applications. Its unique properties, broad range of applications, and cost-effective benefits make it an indispensable tool for electrical engineers and technicians alike. By adopting proper usage techniques and conducting regular maintenance, users can enhance the longevity and reliability of their electrical systems, ultimately contributing to safer and more efficient power distribution networks.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025