Exploring the Benefits of 3M Linerless Rubber Splicing Tape

In today's fast-paced industrial environments, the need for reliable, durable, and efficient solutions for splicing and insulating applications is more critical than ever. One standout product in this realm is the 3M Linerless Rubber Splicing Tape, renowned for its superior performance and versatility. As businesses increasingly recognize the importance of quality materials in their operations, understanding the features and advantages of linerless rubber splicing tape is essential.

What is Linerless Rubber Splicing Tape?

3M Linerless Rubber Splicing Tape is a self-fusing, rubber-based tape designed for insulation and splicing applications in various industries. Unlike traditional tapes, this linerless version does not have a release liner, making it easy to handle and apply. This innovative design delivers several significant benefits, particularly in electrical and mechanical environments where durability and reliability are paramount.

Key Features

1. Self-Fusing Nature One of the standout features of this tape is its self-fusing capability. When wrapped around an object, the tape adheres to itself, forming a strong, waterproof bond without the need for adhesive. This property allows it to conform tightly to irregular shapes, ensuring comprehensive coverage and insulation.

2. Temperature Resistance The 3M Linerless Rubber Splicing Tape can withstand high temperatures, making it suitable for applications in harsh environments. It can endure temperatures ranging from -10°F to 221°F (-23°C to 105°C), ensuring it remains effective in extreme conditions.

3. Durability Made from high-quality rubber, the tape exhibits excellent resistance to abrasion, moisture, and UV rays. This durability not only extends the lifespan of the splices but also reduces the need for frequent replacements, ultimately saving on maintenance costs.

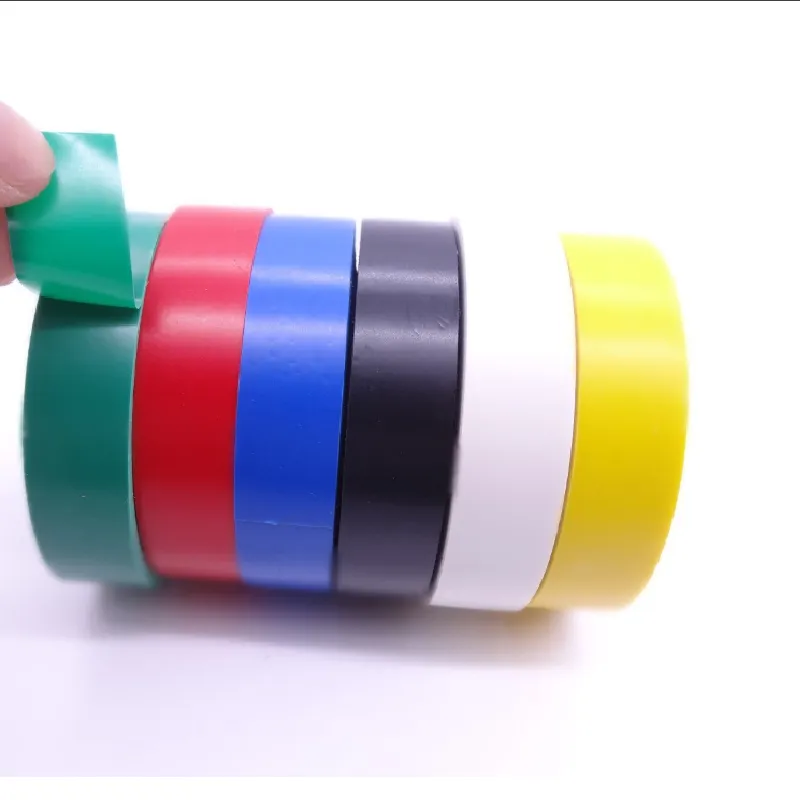

3m linerless rubber splicing tape

4. Electrical Properties This tape offers exceptional electrical insulation properties, making it suitable for use in electrical splicing tasks. It can effectively insulate electrical connections, preventing short circuits and ensuring safe operation in various applications.

5. Ease of Use Without a release liner, this tape is straightforward to apply. Users can start wrapping directly from the roll, allowing for quicker and more efficient installations compared to traditional tapes.

Applications

The versatility of 3M Linerless Rubber Splicing Tape makes it suitable for a wide range of applications. Common uses include

- Electrical Splicing Ideal for insulating and protecting electrical splices, particularly in automotive, electrical distribution, and maintenance environments. - Cable Bundling The self-fusing nature allows for tight and secure bundling of cables, reducing the risk of damage and maintaining organization in wiring systems. - Repairing and Sealing It can be used to repair damaged insulation on wires and cables, as well as for sealing joints and connections against moisture ingression.

Conclusion

In conclusion, 3M Linerless Rubber Splicing Tape presents an innovative solution for a variety of industrial applications, combining robustness, durability, and user-friendliness. Its self-fusing capabilities, resistance to temperature and moisture, and exceptional electrical insulation properties position it as a superior choice for professionals seeking reliable materials. Whether in electrical maintenance, automotive applications, or general repairs, this linerless tape proves to be an invaluable addition to any toolkit. By choosing quality materials like 3M Linerless Rubber Splicing Tape, businesses can enhance their operational efficiency and ensure long-term reliability in their projects.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025