The Benefits of 3M Linerless Rubber Splicing Tape

In the world of industrial adhesives and tapes, 3M has long been recognized as a leader, thanks to its commitment to innovation and quality. One of its standout products is the 3M Linerless Rubber Splicing Tape, a versatile and highly effective solution for electrical and mechanical applications. This tape is designed to provide superior insulation and protection for various splicing and wrapping tasks, making it an invaluable asset in both commercial and residential settings.

What is Linerless Rubber Splicing Tape?

3M Linerless Rubber Splicing Tape is a type of self-fusing tape made from a high-quality rubber backing. Unlike traditional tapes that come with a protective liner, this linerless design allows for easy application without the hassle of removing a backing. The tape adheres to itself when wrapped tightly around a surface, creating a durable and seamless bond. This unique feature not only simplifies the application process but also reduces waste associated with discarded liners.

Key Features

1. Self-Fusing Technology The self-fusing capabilities of this tape mean that it creates a permanent bond without the need for adhesives. This is particularly beneficial in environments where conventional tapes might fail due to exposure to heat, moisture, or chemicals.

2. High-Temperature Resistance 3M Linerless Rubber Splicing Tape can withstand high temperatures, making it suitable for applications that involve heat exposure. With a thermal resistance that can handle temperatures up to 180°F (82°C), it is often used in electrical installations near engines or other heat-generating equipment.

3. Electrical Insulation This tape provides excellent electrical insulation, with a dielectric strength that ensures effective protection against electrical hazards. It is ideal for splicing wires, as it prevents electrical shorts and ultimately enhances safety.

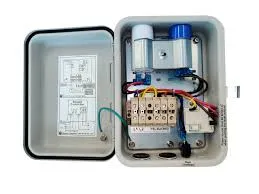

3m linerless rubber splicing tape

4. Weather Resistance Designed to resist moisture and UV radiation, this tape is suitable for both indoor and outdoor applications. Its durability ensures that it won't degrade when exposed to the elements, making it perfect for outdoor electrical repairs.

5. Ease of Use The linerless design eliminates the need for tedious backing removal, allowing users to apply the tape easily and efficiently. This feature saves time and effort, which can be particularly valuable in large-scale projects or maintenance tasks.

Applications

3M Linerless Rubber Splicing Tape is used across a wide range of industries. In electrical applications, it is commonly employed for insulating, protecting, and splicing wires and cables. In automotive settings, it serves to wrap and protect automotive wiring to prevent shorts and damage from heat or chemicals. Additionally, it can be used in HVAC systems, outdoor lighting, and even for plumbing repairs.

Environmental Considerations

As businesses and consumers become increasingly aware of their environmental impact, the importance of choosing sustainable materials is paramount. 3M's commitment to sustainability includes designing products that minimize waste and enhance efficiency. The linerless design not only conserves material but also reduces the volume of waste generated during application.

Conclusion

In summary, the 3M Linerless Rubber Splicing Tape is an exemplary product that offers a host of benefits across various applications. Its self-fusing technology, high-temperature resistance, and excellent electrical insulation make it a go-to choice for professionals and DIY enthusiasts alike. By opting for this innovative tape, users enhance both the effectiveness and efficiency of their projects while also adhering to environmentally conscious practices. Whether you are in construction, automotive, or simply tackling a home improvement project, 3M Linerless Rubber Splicing Tape stands out as a reliable solution that deserves a place in your toolkit.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025