Understanding the Benefits of Advancing with PVC Tape at 7%

In today’s fast-paced world, the demand for efficient and reliable materials in various industries is ever-increasing. Among these critical materials, PVC (Polyvinyl Chloride) tape has carved out a significant niche, especially with an advance rate of 7%. This article explores the attributes, applications, and advantages of PVC tape, underlining why its advancement is noteworthy.

What is PVC Tape?

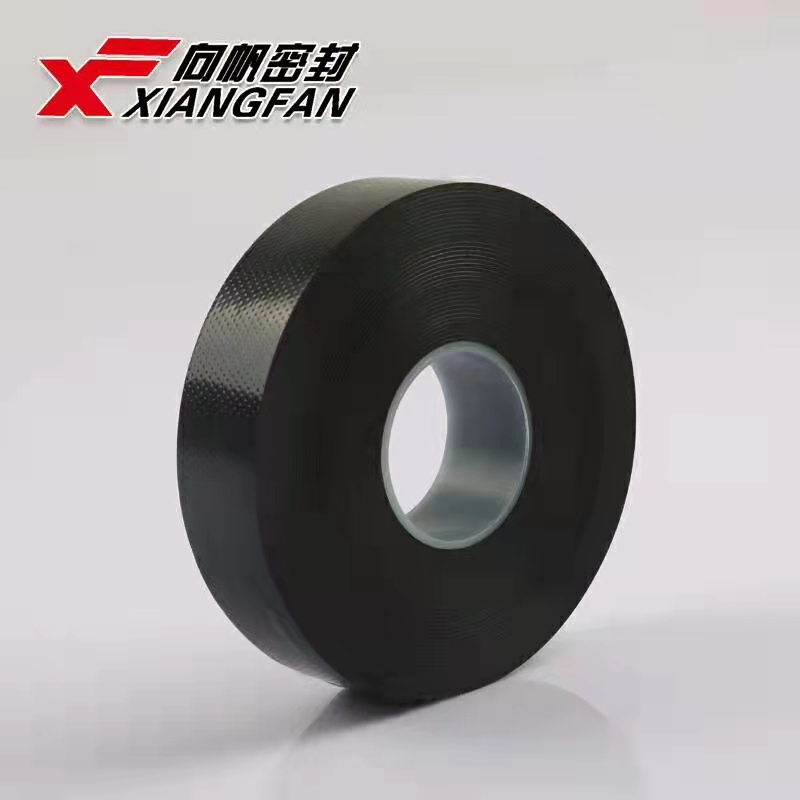

PVC tape is a type of adhesive tape made from polyvinyl chloride, a plastic material known for its durability, flexibility, and resistance to environmental factors. The tape is often coated with a pressure-sensitive adhesive that allows it to stick securely to a variety of surfaces. It is available in various colors, thicknesses, and sizes, making it a versatile option for numerous applications.

Advantages of PVC Tape

One of the main advantages of PVC tape is its excellent insulation properties. It is widely used in the electrical industry for insulating wires and cables. The tape’s ability to withstand high voltages without compromising its integrity makes it an ideal choice for electricians and electronic manufacturers. Furthermore, its flexibility allows for easy application around corners and irregular shapes, enhancing its effectiveness in a range of electrical setups.

Another benefit of PVC tape is its durability. It is resistant to abrasion, moisture, and UV light, making it suitable for both indoor and outdoor applications. This resiliency extends the lifespan of the materials it protects, reducing the need for frequent maintenance or replacement. In environments that expose materials to harsh conditions, PVC tape provides a reliable barrier, ensuring that operations continue smoothly without interruptions.

Applications Across Industries

advance at7 pvc tape

PVC tape is not limited to electrical applications; its versatility spans several industries including construction, automotive, and packaging. In construction, it plays a crucial role in sealing joints, bundling materials, and providing a waterproof barrier. The packaging industry also relies on PVC tape to secure boxes and pallets, protecting products during transit.

Moreover, in the automotive sector, PVC tape is often employed for decorative purposes as well as for insulation and wiring applications. It can be used to color-code wires, mark boundaries, or add grip to surfaces, showcasing its multifunctional nature.

Environmental Considerations

As industries continue to evolve, the environmental impact of materials used becomes ever more critical. PVC tape, while immensely beneficial, has faced scrutiny due to its plastic composition. However, many manufacturers are steadily transitioning towards more eco-friendly production processes and recyclable materials. Innovations in PVC tape technology aim to reduce its ecological footprint while maintaining its advantageous properties.

The Future of PVC Tape

With an advance rate of 7%, the demand for PVC tape is projected to grow alongside advancements in technology and material science. New formulations promise enhanced performance features such as improved adhesive strength, greater temperature resistance, and even biodegradable options. As industries seek innovative solutions to meet their operational needs, PVC tape is poised to remain a key player.

Conclusion

In conclusion, PVC tape stands out as a valuable resource across various industries, offering remarkable benefits through its durability, flexibility, and insulation capabilities. With its advancements continuing at a robust rate, it is clear that PVC tape not only meets existing demands but is also evolving to address future challenges. Whether in electrical applications, construction, automotive, or packaging, PVC tape is indispensable, contributing to more efficient and effective operations. As industries embrace sustainable practices and innovative technologies, the journey of PVC tape will undoubtedly lead to even greater advancements in the years to come.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025