The Importance of Aisle Marking Tape in Modern Industries

In the bustling world of industrial operations, efficient organization is key to maintaining productivity and safety. One often-overlooked tool that plays a crucial role in achieving this is aisle marking tape. This simple yet effective product helps to delineate areas within a facility, guiding workers and ensuring the smooth flow of operations.

Understanding Aisle Marking Tape

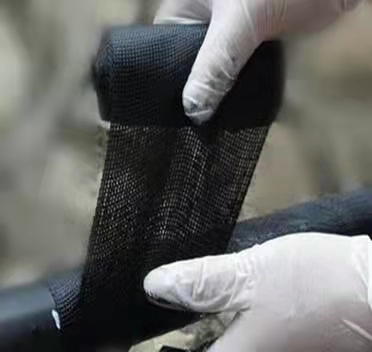

Aisle marking tape is a type of adhesive tape specifically designed for marking walkways, aisles, and other important zones within a facility. Unlike regular tape, aisle marking tape is constructed to be durable, resistant to wear and tear, and capable of withstanding the rigors of everyday industrial activities. It comes in a variety of colors and sizes, allowing businesses to customize markings according to their specific needs.

Enhancing Safety and Efficiency

One of the most significant advantages of aisle marking tape is its ability to improve workplace safety

. In warehouses and production facilities, clear pathways are necessary to prevent accidents and injuries. By marking designated walkways, loading zones, and emergency exits, businesses can reduce the risk of collisions between workers, forklifts, and other equipment.Moreover, clear aisle markings help employees navigate the space more effectively. When workers know precisely where they should walk and where equipment is operating, the likelihood of accidents diminishes significantly. This organization not only fosters a safer environment but also enhances overall operational efficiency. Workers can move quickly and confidently, minimizing downtime and improving productivity.

Visual Management Tool

aisle marking tape

Aisle marking tape is also an essential component of visual management systems. In manufacturing and logistics, visual cues facilitate better communication and understanding among team members. Different colors can be utilized to denote various sections of a facility or to indicate specific functions. For instance, yellow may be used for walkways, while red could signify hazardous zones.

By employing a color-coded system, businesses can convey critical information at a glance. Employees can immediately recognize which areas are safe for walking and which are restricted, thereby streamlining processes and reducing confusion. This visual organization is particularly beneficial in larger facilities where distances can be substantial, and clear guidance is needed.

Cost-Effective Solution

Implementing aisle marking tape is a cost-effective solution for facilities looking to improve safety and organization. Compared to more permanent solutions like paint, marking tape can be easily applied and removed without causing long-term damage to floors. This adaptability allows businesses to reconfigure their layouts as needed without incurring significant expenses.

Additionally, the installation of aisle marking tape is straightforward and can often be completed by existing staff members. This not only saves labor costs but also ensures that the implementation can be done quickly and efficiently, without the need for specialized contractors.

Conclusion

In conclusion, aisle marking tape is an invaluable asset for modern industries. Its role in enhancing safety, improving efficiency, and providing quick visual cues cannot be overstated. As businesses continue to evolve and seek methods to optimize their operational workflows, the use of aisle marking tape emerges as a simple, effective, and economical solution. By investing in this essential tool, companies can create well-organized and safer workplaces that foster productivity and employee well-being.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025