Understanding Amalgamating Tape A Versatile Solution for Electrical Insulation

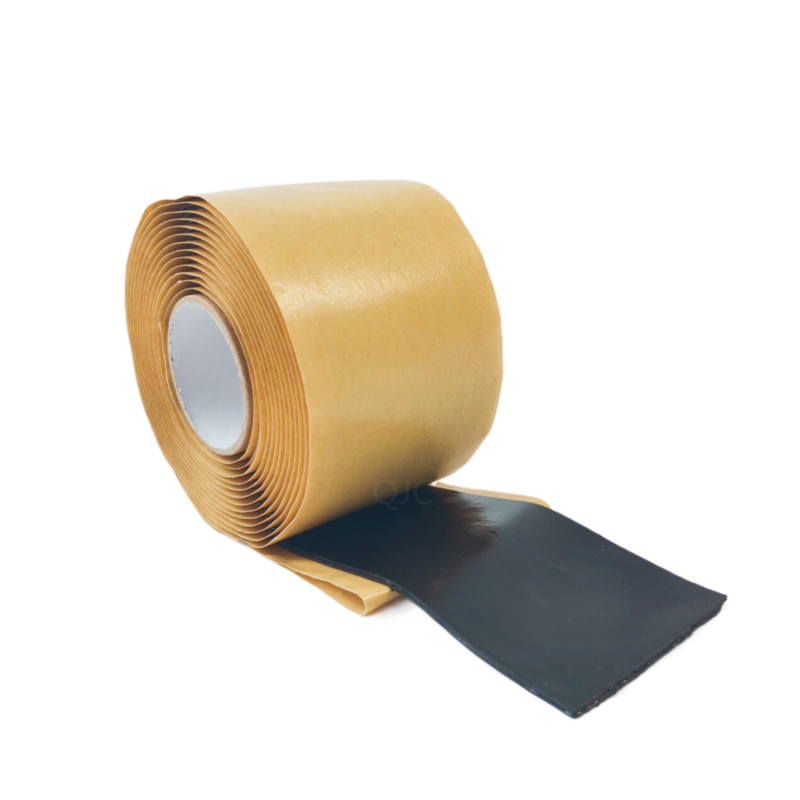

Amalgamating tape, often referred to in the electrical industry, is a specialized type of tape that plays a crucial role in electrical insulation and jointing applications. Unlike traditional adhesive tapes, amalgamating tape does not contain any adhesive properties. Instead, it relies on a unique blend of materials that allow it to bond to itself when stretched and wrapped around an object. This self-bonding characteristic makes it an invaluable tool for a variety of applications, particularly in environments that require reliable insulation, protection against moisture, and resistance to environmental elements.

One of the primary components of amalgamating tape is its rubber or polymer base, which provides excellent electrical insulation properties. This feature is especially important in electrical applications, where safeguarding against short circuits and electrical failures is essential. When applied correctly, amalgamating tape can achieve high dielectric strength, ensuring that it can withstand high voltages without breaking down. This makes it suitable for use in electrical wiring, transformers, and even high-voltage power lines.

Another advantage of amalgamating tape is its flexibility and ease of use. It can be applied to various surfaces, including irregularly shaped or rough surfaces, without the need for additional adhesives. The tape stretches as it is wrapped around the object, conforming to its shape and creating a secure, watertight seal. This feature is particularly useful when insulating wires, as it eliminates the risk of moisture ingress, which can lead to corrosion and electrical failures over time.

In addition to its electrical insulation properties, amalgamating tape also provides mechanical protection. It functions as a cushion against abrasion, impacts, and tearing. This is especially advantageous in industrial settings where equipment is subjected to harsh conditions. By applying amalgamating tape to vulnerable areas, one can extend the life of cables and wires, reducing the frequency of replacements and repairs.

amalgamating tape

Beyond electrical applications, amalgamating tape is also used in plumbing and HVAC installations. It can be utilized to seal joints in pipes and ducts, preventing leaks and improving overall efficiency. The tape’s resistance to weathering and UV exposure further enhances its applicability in outdoor and exposed environments.

Moreover, amalgamating tape is compatible with various substrates, including rubber, metal, and plastic. This versatility allows it to be used in a wide range of industries, from telecommunications to automotive manufacturing. Its non-toxic composition also ensures that it is safe for use in sensitive environments, such as hospitals and clean rooms.

When selecting amalgamating tape, it is essential to consider several factors, such as the temperature range, voltage rating, and specific application requirements. Different formulations may exist to address specific needs, ensuring that users can find a product that meets their particular demands.

In conclusion, amalgamating tape is an indispensable tool in modern electrical and mechanical applications. Its self-bonding capabilities, excellent insulation properties, and mechanical protection make it a preferred choice among professionals across various industries. As technology continues to advance, the development of amalgamating tape will likely evolve to meet the changing needs of users. Whether insulating wires, protecting against moisture, or providing mechanical cushioning, amalgamating tape remains a go-to solution for reliable and efficient insulation. With its myriad of benefits, it is no surprise that amalgamating tape is celebrated for its effectiveness and versatility in a multitude of applications.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025