How to Use Amalgamating Tape A Comprehensive Guide

Amalgamating tape, often referred to as insulating tape or self-fusing tape, is a versatile product widely used in electrical and plumbing applications. Unlike traditional adhesive tapes, this type of tape fuses to itself when wrapped tightly, creating a strong, waterproof seal. Below is a guide on how to properly use amalgamating tape for optimal results.

Step 1 Prepare the Surface

Before applying amalgamating tape, it’s essential to prepare the surface properly. Ensure that the surface is clean, dry, and free of any dust, grease, or moisture. For electrical applications, turn off the power supply to the area. If working on pipes, make sure they are dry and clean to guarantee a proper seal.

Step 2 Start Wrapping

Begin by taking the end of the amalgamating tape and anchoring it to the surface you intend to cover. It is crucial to stretch the tape slightly as you wrap it around the object. This stretching activates the self-fusing properties of the tape, ensuring a stronger bond. Aim to overlap each layer by about half the width of the tape to enhance the sealing effect.

Step 3 Apply Multiple Layers

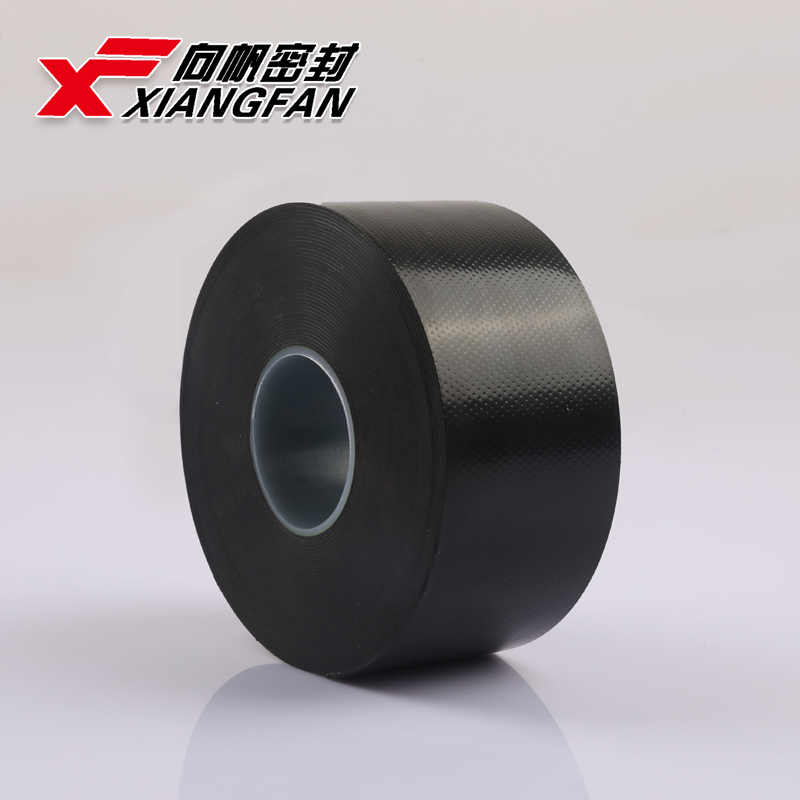

amalgamating tape how to use

For optimal insulation and protection, especially in electrical applications, apply multiple layers of amalgamating tape. Generally, two to three layers should suffice, but this can vary depending on the specific application and environmental conditions. Be sure to maintain tension while wrapping to prevent any gaps.

Step 4 Finish and Secure

Once you have reached the end of the area you want to cover, cut the tape and press the end firmly against the wrapped section. The self-fusing properties will ensure that it adheres well without needing additional adhesives. Allow the tape to cure for at least an hour for the best results.

Step 5 Inspect the Application

After the tape has cured, inspect your work to ensure that the seal is firm and there are no weak spots. This step is particularly important in electrical applications, where even minor imperfections can lead to hazards.

In summary, amalgamating tape is an effective solution for a variety of applications, especially in ensuring safety and moisture resistance. By following these steps, you can achieve a reliable and long-lasting seal. Always remember to prioritize safety when working with electrical components or plumbing systems to avoid any accidents.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025