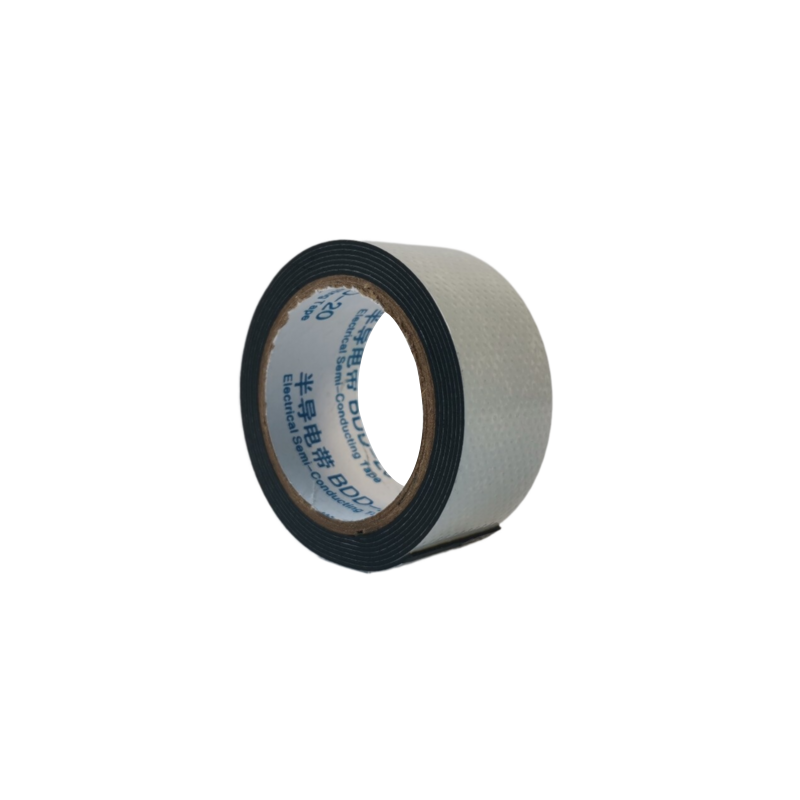

PlB self-amalgamating Tape

Back to list

Feb . 13, 2025 08:34

Amalgamating tape is an essential tool for many professionals involved in electrical, plumbing, and other technical fields. This versatile, non-adhesive tape is designed for jointing, waterproofing, and insulating a variety of materials. Understanding how to use amalgamating tape effectively can enhance the durability and safety of your projects.

For plumbing repairs, amalgamating tape provides a quick temporary fix for leaks. Start wrapping a few inches away from the leak source, working toward it and beyond, as this method increases the seal's integrity. Remember, while amalgamating tape is effective in providing temporary seals, incorporating a more permanent solution is advisable for long-term reliability. The tape is also resistant to UV, oils, solvents, and chemicals. This property is especially beneficial for automotive or outdoor uses, where exposure to harsh conditions is common. When using it to protect against environmental factors, ensure the final wrap is smooth and uniformly tight, reinforcing its protective barrier. Safety is another critical aspect of using amalgamating tape. Wearing gloves can help prevent skin oils from interfering with the tape's performance. Additionally, ensure that the tape is stored properly when not in use. Keep it in a cool, dry place and avoid prolonged exposure to direct sunlight or heat, which could degrade its quality over time. In summary, amalgamating tape is a versatile tool that enhances safety, efficiency, and reliability in numerous applications. By following a few best practices—cleaning the surface, stretching and overlapping the tape, and ensuring a tight seal—you can make the most of this indispensable tape. Whether you're an electrician, plumber, or simply tackling a DIY project, understanding how to use amalgamating tape ensures your work remains durable and effective.

For plumbing repairs, amalgamating tape provides a quick temporary fix for leaks. Start wrapping a few inches away from the leak source, working toward it and beyond, as this method increases the seal's integrity. Remember, while amalgamating tape is effective in providing temporary seals, incorporating a more permanent solution is advisable for long-term reliability. The tape is also resistant to UV, oils, solvents, and chemicals. This property is especially beneficial for automotive or outdoor uses, where exposure to harsh conditions is common. When using it to protect against environmental factors, ensure the final wrap is smooth and uniformly tight, reinforcing its protective barrier. Safety is another critical aspect of using amalgamating tape. Wearing gloves can help prevent skin oils from interfering with the tape's performance. Additionally, ensure that the tape is stored properly when not in use. Keep it in a cool, dry place and avoid prolonged exposure to direct sunlight or heat, which could degrade its quality over time. In summary, amalgamating tape is a versatile tool that enhances safety, efficiency, and reliability in numerous applications. By following a few best practices—cleaning the surface, stretching and overlapping the tape, and ensuring a tight seal—you can make the most of this indispensable tape. Whether you're an electrician, plumber, or simply tackling a DIY project, understanding how to use amalgamating tape ensures your work remains durable and effective.

Next:

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025