The Importance of Automotive Harness Tape in Vehicle Manufacturing

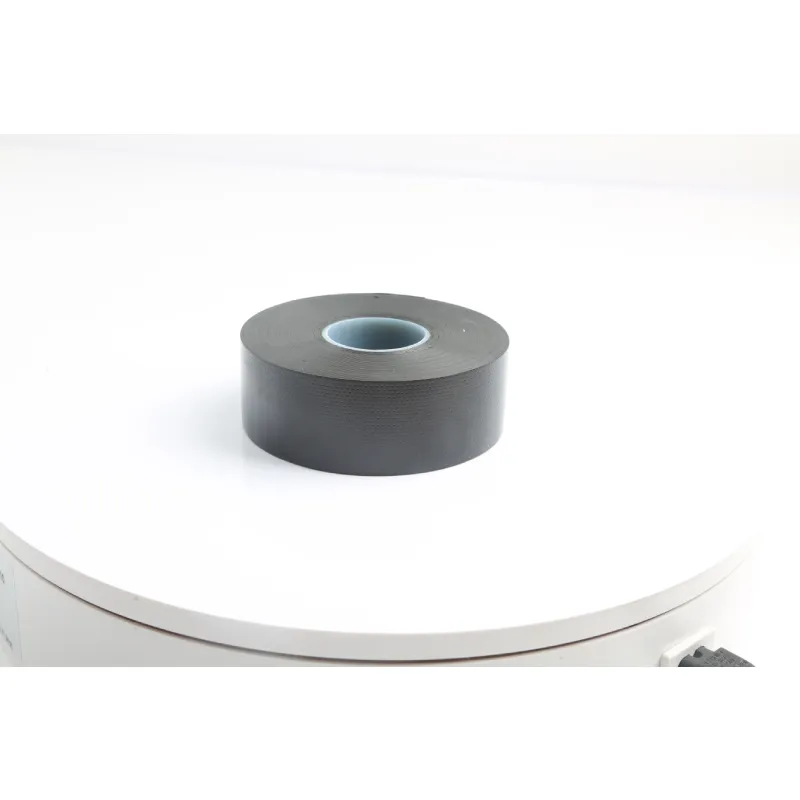

In the intricate world of automotive manufacturing, several components work in harmony to create the vehicles we rely on today. Among these, automotive harness tape plays a crucial yet often overlooked role. This specialized tape is essential for the insulation, protection, and organization of wiring harnesses within vehicles, ensuring that electrical systems function optimally.

Automotive wiring harnesses are intricate assemblies of wires and connectors that transmit power and signals throughout a vehicle. Given the complex electrical demands of modern automobiles, effective insulation and protection of these wiring systems are paramount. Automotive harness tape provides a reliable solution for these needs. Constructed from various materials including PVC, cloth, and even advanced composites, this tape is designed to withstand harsh environments, including extreme temperatures, moisture, and exposure to chemicals.

One of the primary functions of automotive harness tape is to provide insulation. Electric currents running through wires can create heat, and inadequate insulation may lead to short circuits or even fires. Automotive harness tape offers a high degree of electrical resistance, ensuring that currents remain contained within their designated paths. This insulation not only enhances safety but also prolongs the longevity of the wiring harness.

automotive harness tape

In addition to insulation, automotive harness tape serves as a protective layer. Vehicle manufacturing involves various processes where vibration and movement can place stress on wiring harnesses. The use of harness tape helps to secure wires and prevent wear and tear, which is critical in maintaining functionality over time. This durability is particularly important in high-performance vehicles where electrical systems are pushed to their limits.

Moreover, automotive harness tape contributes significantly to the organization of wiring within a vehicle. A neat and tidy wiring harness is not just a matter of aesthetics; it is essential for ease of maintenance and troubleshooting. By bundling wires together, the tape keeps them organized, making it easier for technicians to access particular circuits when repairs are needed. This organization reduces the likelihood of errors during repairs and maintenance, ultimately saving time and costs for vehicle manufacturers and owners alike.

Additionally, the adhesive qualities of automotive harness tape must not be underestimated. A high-quality tape will adhere strongly to various surfaces, ensuring that it remains in place even under challenging conditions. This adhesion is crucial not only for the integrity of the wiring harness but also for the overall performance of the vehicle's electrical systems.

In conclusion, automotive harness tape may seem like a minor component in the grand scheme of vehicle manufacturing, but its significance cannot be overstated. By providing insulation, protection, and organization to wiring harnesses, it plays a vital role in the safety and efficiency of modern vehicles. As technology continues to advance and vehicles become increasingly complex, the importance of reliable automotive harness tape will likely grow, making it an essential consideration for engineers and manufacturers alike. Whether for fuel efficiency, performance, or safety, harness tape is a key player in the ever-evolving automotive landscape.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025