The Importance of Auto Wire Harness Tape in Vehicle Manufacturing

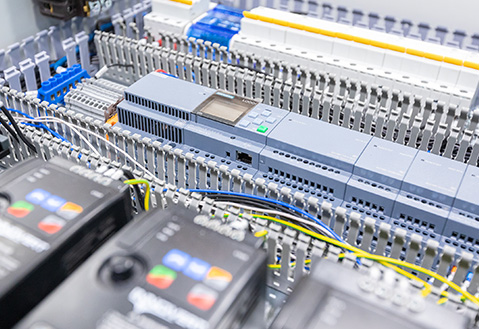

In the automotive industry, the wiring harness is a crucial component that connects all electrical systems within a vehicle. This complex network of wires allows for the seamless operation of the engine, lights, infotainment systems, and safety features. However, the efficiency and longevity of these wiring harnesses depend significantly on the materials used in their construction, particularly the adhesive tapes that aid in cable organization and protection. Among these, auto wire harness tape plays a vital role.

Auto wire harness tape, typically made from high-quality materials such as vinyl or cloth, is designed specifically for automotive applications. Its primary purpose is to bundle wires together, keeping them organized and preventing tangling or damage during the manufacturing process and throughout the vehicle’s life cycle. The tape is carefully engineered to withstand the harsh conditions often found in automotive environments, including extreme temperatures, moisture, and exposure to chemicals.

One of the key benefits of auto wire harness tape is its insulation properties. Electrical systems can be sensitive to interference, and a well-insulated harness can minimize the risk of short circuits and electromagnetic interference. This feature is particularly important given the number of electronic components in modern vehicles, which often operate at different voltage levels. By using high-quality tape designed for automotive wiring, manufacturers can ensure that the electrical integrity of the harness is maintained.

Additionally, auto wire harness tape contributes to the overall safety of the vehicle. Properly bundled and insulated wiring reduces the likelihood of wear and tear, which can lead to electrical failures. Such failures could result in vehicle malfunctions that not only pose risks to drivers and passengers but could also lead to unsafe driving conditions. Therefore, investing in reliable wire harness tape is a proactive approach to enhancing vehicle safety.

auto wire harness tape

Another significant advantage of auto wire harness tape is its ease of application. Manufacturers can quickly wrap the tape around bundles of wires or cables, facilitating an efficient assembly process. Unlike other methods of securing wires, such as zip ties or clamps, harness tape provides a clean and uniform finish that is aesthetically pleasing as well. This is becoming increasingly important as manufacturers seek to provide not only functional but also visually appealing products.

Moreover, the adhesive used in auto wire harness tape is designed to ensure a strong bond without leaving residue when removed. This characteristic is crucial during vehicle assembly, maintenance, or any necessary repairs. Technicians can easily access the wiring without damaging the tape or the underlying harness, ensuring that repairs can be carried out efficiently.

As automotive technology evolves, so does the design and functionality of wire harness tapes. Newer generations of tapes may incorporate advanced features such as heat resistance, UV protection, or even self-adhesive capabilities for easier installation. As vehicles increasingly integrate high-performance electronics and more sophisticated power systems, the demand for reliable and durable wire harness tape is only expected to rise.

In conclusion, auto wire harness tape is an indispensable component in the automotive manufacturing process. With its essential roles in insulation, organization, safety, and ease of application, the right tape can significantly enhance the overall performance and longevity of vehicle electrical systems. As the automotive industry moves towards more complex electrical architectures, the importance of effective wire management strategies, including the use of high-quality harness tape, will become increasingly apparent. Manufacturers and technicians must recognize the value of this simple yet critical tool to ensure that they produce safe, reliable, and efficient vehicles.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025