Adhesive Cloth Automotive Wiring Harness Tape A Comprehensive Overview

In the automotive industry, ensuring the safety and reliability of wiring harnesses is paramount. One of the essential components used in the assembly and protection of these harnesses is adhesive cloth automotive wiring harness tape. This specialized tape offers unique characteristics that make it particularly suitable for automotive applications, ensuring that wiring systems remain protected, organized, and efficient.

Composition and Features

Adhesive cloth automotive wiring harness tape is typically made from a combination of woven cloth, coated with a high-performance adhesive. The cloth material provides robust durability while maintaining a flexible structure. This tape is designed to withstand the rigors of automotive environments, including fluctuations in temperature, exposure to moisture, and resistance to chemicals and automotive fluids like oil, coolant, and gasoline.

One of the significant features of this tape is its strong adhesive backing, which ensures that the tape firmly adheres to the wire harnesses and surrounding surfaces. This prevents slippage or peeling, which can lead to exposure of wires and potential electrical failures or short circuits. Additionally, the cloth material allows for sound dampening, reducing vibrations that could affect wire integrity over time.

Benefits in Automotive Applications

Use of adhesive cloth tape for wiring harnesses provides several benefits. First and foremost is its protective capability. The tape protects the wiring from abrasion, impacts, and environmental factors, which is crucial for maintaining vehicle longevity. By shielding the wires, the tape helps to prevent wear and tear, thus minimizing the risk of electrical failures and enhancing vehicle safety.

Moreover, this tape aids in organization. When bundling together multiple wires, the adhesive cloth tape ensures they remain grouped neatly, reducing the risk of entanglement and facilitating easier maintenance. This organized approach is especially critical during the manufacturing process and later during repairs or diagnostic checks. Technicians can quickly identify wiring issues and access components without disturbing other systems.

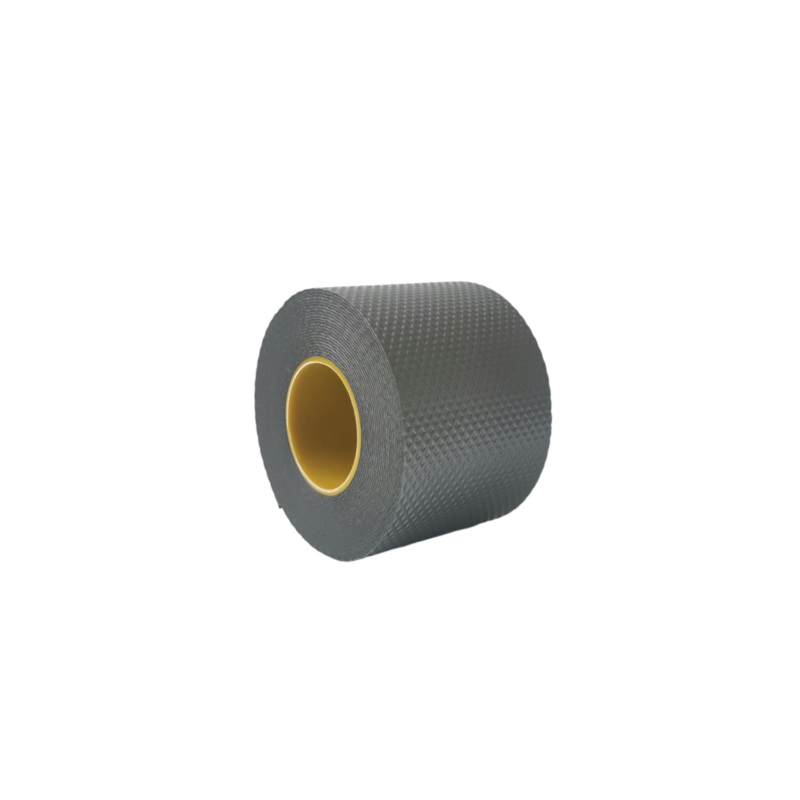

adhesive cloth automotive wiring harness tape

Installation and Applicability

Installation of adhesive cloth automotive wiring harness tape is straightforward. It can be easily torn by hand, making it convenient for workers who may be assembling or repairing wiring systems under time constraints. The tape can conform to different shapes and sizes of wiring bundles, ensuring comprehensive coverage regardless of the complexity of the harness.

This tape is suitable for various applications beyond just wiring harness protection. It is often utilized in securing hoses, insulation materials, and even in bundling pneumatic and hydraulic lines in vehicles. Its versatility has made it an indispensable tool in automotive assembly and repair shops worldwide.

Environmental Considerations

In recent years, the automotive industry has made significant strides in sustainability. Many manufacturers are now producing adhesive cloth automotive wiring harness tape using eco-friendly materials and processes. This shift not only reduces the environmental impact of manufacturing but also addresses the increasing consumer demand for sustainable products.

Conclusion

Adhesive cloth automotive wiring harness tape plays an essential role in the functionality and safety of modern vehicles. Its unique combination of durability, flexibility, and strong adhesion ensures that wiring harnesses are protected from external elements while maintaining organization for ease of access and repair. As the automotive industry continues to evolve, the importance of high-quality materials like this tape cannot be overstated, leading to better-performing vehicles, enhanced safety, and a more sustainable future. Whether for assembly or repair, adhesive cloth tape is a vital resource that underscores the automotive sector's commitment to quality and excellence.

-

Self Amalgamating Tape: Redefining Electrical Insulation and ProtectionNewsAug.07,2025

-

Seal Strip Solutions: Revolutionizing Energy Efficiency and Comfort in Modern BuildingsNewsAug.07,2025

-

High Voltage Electrical Tape: Powering Safety and Reliability in Modern InstallationsNewsAug.07,2025

-

Flex Tape Waterproof: Transforming the Future of Instant RepairsNewsAug.07,2025

-

Elevate Electrical Safety Standards with High-Performance PVC Electrical TapeNewsAug.07,2025

-

Butyl Rubber Tape: The Ultimate Solution for Reliable Sealing and WaterproofingNewsAug.07,2025