The Essentials of Automotive Electrical Tape Fabric

When it comes to automotive maintenance and repair, a variety of tools and materials are essential for ensuring safety and performance. Among these, automotive electrical tape fabric plays a crucial role that often goes underappreciated. This specialized tape is designed to insulate, protect, and repair electrical components in vehicles, making it an indispensable asset for any mechanic or DIY enthusiast.

Understanding Automotive Electrical Tape Fabric

Automotive electrical tape fabric is a type of adhesive tape specifically engineered for automotive applications. It is made from high-grade materials that can withstand extreme temperatures, moisture, and other environmental factors typically found in vehicles. Unlike regular tape, automotive electrical tape is designed to handle the stress of constant movement and temperature fluctuations without losing its adhesive properties.

Typically, it features a durable cloth backing, providing superior strength and flexibility. This material is designed to resist abrasions and tears, which is critical when dealing with the rough conditions inherent in automotive environments.

Key Properties

1. Temperature Resistance Given the varying temperatures in automotive applications—from the heat of the engine to cooler ambient conditions—automotive electrical tape fabric can typically endure a range of temperatures without losing its structural integrity.

2. Chemical Resistance Cars are exposed to various fluids, such as oil, coolant, and gasoline. Automotive electrical tape is designed to resist chemical degradation, ensuring longevity and reliability in harsh conditions.

3. Electrical Insulation This tape is not just sticky; it provides excellent electrical insulation, which is vital for preventing shorts and ensuring safe vehicle operation. Its dielectric properties ensure that electrical currents are contained, preventing potential hazards.

4. Flexibility The fabric composition of this tape allows it to conform to various shapes and sizes of electrical components. Whether wrapping wires, covering connectors, or sealing damaged insulation, its flexible nature makes it easy to work with in tight spaces.

5. UV Resistance Many applications occur in exposed areas where direct sunlight can degrade materials. Automotive electrical tape fabric typically has UV-resistant properties, safeguarding it from sun damage and ensuring it maintains its effectiveness over time.

Applications in Automotive Repair and Maintenance

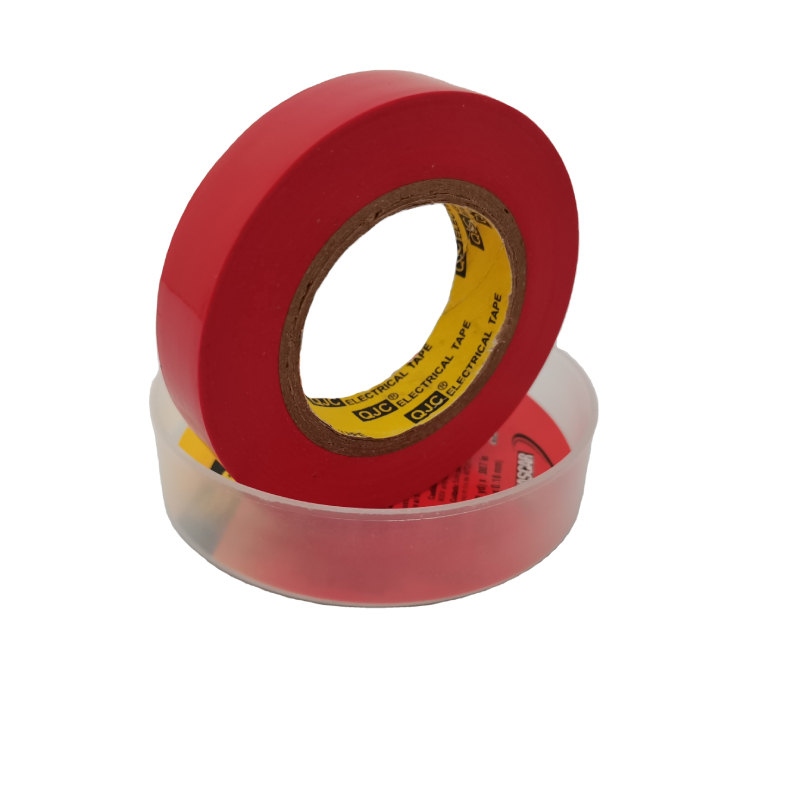

automotive electrical tape fabric

Automotive electrical tape fabric serves multiple purposes in the realm of vehicle maintenance

- Wire Insulation One of its primary uses is insulating electrical wires. Whether repairing a damaged wire or bundling multiple wires together, this tape prevents electrical shorts and protects the integrity of vehicle wiring systems.

- Connector Protection Automotive connectors can often be exposed to moisture and dirt. Using electrical tape to seal and protect these connectors prolongs their lifespan and ensures proper electrical flow.

- Repairing Damaged Insulation In the case that wiring insulation becomes frayed or damaged, automotive electrical tape can be a swift and efficient fix, providing a temporary solution until more permanent repairs can be made.

- Bundling and Organizing Wires In the automotive industry, neatness is crucial. Electrical tape can be used to tidy up wiring harnesses, preventing tangling and facilitating easier troubleshooting in the future.

Best Practices for Use

To maximize the effectiveness of automotive electrical tape fabric

1. Surface Preparation Ensure that the surface is clean and dry before applying the tape to guarantee maximum adhesion. 2. Layering When wrapping wires, it’s often best to apply the tape in overlapping layers, ensuring comprehensive coverage and insulation.

3. Check for Damage After application, regularly check the taped areas for wear or damage, especially if the vehicle is frequently exposed to extreme conditions.

Conclusion

Automotive electrical tape fabric is a vital component in the safety and efficiency of vehicle electrical systems. Its durability, flexibility, and protective qualities make it ideal for a wide range of applications, from simple repairs to essential maintenance tasks. By understanding its properties and applications, automotive professionals and enthusiasts can enhance their repair skills, ensuring long-lasting and reliable vehicle performance. Whether in a garage or on the roadside, having quality automotive electrical tape fabric can make all the difference in a vehicle's upkeep.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025