The Importance of Automotive Harness Tape in Vehicle Manufacturing and Maintenance

In the intricate world of automotive manufacturing and maintenance, the efficiency and safety of vehicles largely depend on the electrical systems that power them. At the heart of these systems lies the automotive wiring harness, a complex network of electrical wires and connectors that transmit power and signals throughout the vehicle. To ensure the longevity and reliability of these wire assemblies, automotive harness tape plays a crucial role. This article explores the importance of automotive harness tape, its various types, applications, and benefits.

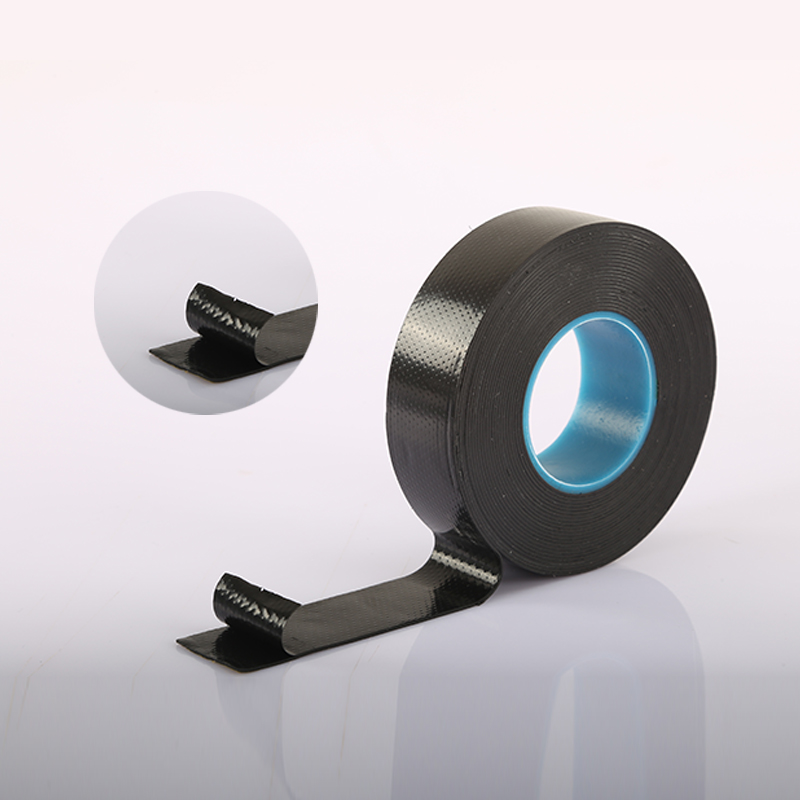

What is Automotive Harness Tape?

Automotive harness tape is a specialized adhesive or non-adhesive tape designed to insulate, bundle, and protect the wiring placed within a vehicle's harness system. This tape is essential in maintaining the integrity of the electrical components by providing durability against environmental factors, mechanical wear, and thermal fluctuations.

Types of Automotive Harness Tape

There are several types of automotive harness tape, each designed for specific applications

1. Vinyl Tape This is a versatile and commonly used tape in automotive applications. It is resistant to moisture, chemicals, and abrasion, making it ideal for under-hood applications. Its flexibility allows it to conform to various shapes and sizes of wiring harnesses.

2. Polyester Tape Known for its strong electrical insulation properties, polyester tape is often used in high-temperature environments. It can withstand heat and is frequently utilized in engine compartments where temperatures can rise significantly.

3. Foam Tape This type of tape offers cushioning and vibration dampening properties. It is particularly beneficial in areas where wires and harnesses may be exposed to constant movement or friction, thereby reducing wear and preventing damage.

4. Heat Shrink Tape Unlike traditional tapes, heat shrink tape is applied to wires and then heated to shrink the tape around the harness. This ensures a tight fit and adds an extra layer of protection against moisture and abrasion.

Applications of Automotive Harness Tape

Automotive harness tape has various applications in vehicle manufacturing and repair

automotive harness tape

- Bundling Wires The primary function of harness tape is to bundle multiple wires together. This not only organizes the wiring but also minimizes the risk of tangling and confusion during repairs.

- Insulation Harness tape serves as an insulating layer, protecting wires from electrical shorts and environmental hazards. This is crucial for maintaining the vehicle's electrical integrity.

- Protection Against Wear and Tear Vehicles are subject to a host of mechanical stresses, including vibrations and movements. Harness tape provides a protective barrier that mitigates wear, extending the life of the wiring harness.

- Aesthetic Appeal Beyond functionality, harness tape can enhance the overall appearance of the wiring system. A clean and organized harness can contribute to better maintenance and troubleshooting during repairs.

Benefits of Using Automotive Harness Tape

The use of automotive harness tape offers several significant advantages

- Durability With the right type of tape, automotive harnesses can withstand the harsh conditions present in vehicles, including extreme temperatures, moisture, and exposure to chemicals.

- Safety Proper insulation and bundling of wires reduce the risk of electrical failures, which can lead to accidents or costly repairs.

- Cost-Effectiveness Investing in quality harness tape can save money in the long run by preventing damage to wiring systems and reducing the likelihood of electrical issues.

- Ease of Installation Most automotive harness tapes are easy to use, enabling quick and effective bundling and insulation, simplifying maintenance and repair work.

Conclusion

In conclusion, automotive harness tape is a vital component in ensuring the safety, reliability, and efficiency of vehicle electrical systems. By choosing the appropriate type of tape for specific applications, manufacturers and technicians can protect wiring harnesses from damage, enhance durability, and ultimately contribute to the vehicle's overall performance. As the automotive industry continues to innovate, the role of harness tape will remain essential in supporting the complex electrical systems that power the vehicles of today and tomorrow.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025