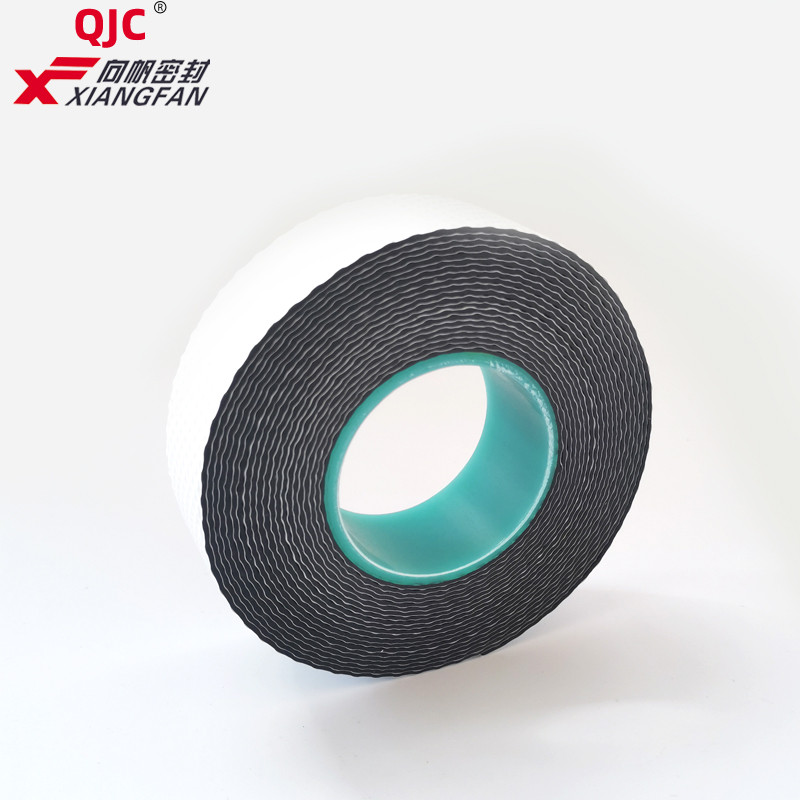

Automotive Wire Harness PVC Tape

Back to list

Mar . 04, 2025 11:38

Automotive wiring harness cloth tape is a pivotal component in the realm of automobile engineering, providing not only functionality but also a significant contribution to vehicular safety and efficiency. With increasing technological advancements and the complexity of electronic systems within vehicles, the need for reliable, durable, and efficient wiring solutions has never been higher. This article delves into the various aspects of automotive wiring harness cloth tapes, focusing on their relevance, effectiveness, and importance in modern automotive applications.

In terms of expertise, manufacturers of automotive wiring harness cloth tapes employ advanced technologies and stringent quality control measures. The production process involves selecting high-performance fibers and adhesives, ensuring that each roll of tape meets the rigorous standards required by the automotive industry. This expertise translates into products that offer not only protection and durability but also enhanced safety for the vehicles in which they are used. The authoritativeness of automotive wiring harness cloth tapes in the industry is established through extensive testing and validation. These tapes undergo various tests to assess their resistance to heat, chemicals, and physical wear and tear. Many manufacturers achieve certifications from recognized automotive industry bodies, assuring users of the high standards met by these tapes. The credibility provided by such certifications positions them as a trustworthy choice for automotive manufacturers seeking reliable wiring solutions. Trustworthiness is further reinforced by the real-world application and feedback from automobile manufacturers and repair specialists. The consistent performance of automotive wiring harness cloth tapes in diverse environmental conditions is a testament to their reliability. Professionals in the automotive industry often emphasize the importance of using high-quality tape to avoid potential electrical issues that can arise from inferior materials. This collective trust and reliance underline the product's importance in maintaining vehicular integrity and performance. In conclusion, automotive wiring harness cloth tape is more than just a protective measure; it is a critical component ensuring efficient and safe operation of vehicles. Its design, backed by expert manufacturing practices and rigorously tested performance metrics, makes it indispensable in modern automotive wiring applications. As vehicles continue to evolve with more advanced electronic systems, the demand for such reliable and efficient tapes is set to increase, highlighting their enduring relevance and necessity in the automotive sector.

In terms of expertise, manufacturers of automotive wiring harness cloth tapes employ advanced technologies and stringent quality control measures. The production process involves selecting high-performance fibers and adhesives, ensuring that each roll of tape meets the rigorous standards required by the automotive industry. This expertise translates into products that offer not only protection and durability but also enhanced safety for the vehicles in which they are used. The authoritativeness of automotive wiring harness cloth tapes in the industry is established through extensive testing and validation. These tapes undergo various tests to assess their resistance to heat, chemicals, and physical wear and tear. Many manufacturers achieve certifications from recognized automotive industry bodies, assuring users of the high standards met by these tapes. The credibility provided by such certifications positions them as a trustworthy choice for automotive manufacturers seeking reliable wiring solutions. Trustworthiness is further reinforced by the real-world application and feedback from automobile manufacturers and repair specialists. The consistent performance of automotive wiring harness cloth tapes in diverse environmental conditions is a testament to their reliability. Professionals in the automotive industry often emphasize the importance of using high-quality tape to avoid potential electrical issues that can arise from inferior materials. This collective trust and reliance underline the product's importance in maintaining vehicular integrity and performance. In conclusion, automotive wiring harness cloth tape is more than just a protective measure; it is a critical component ensuring efficient and safe operation of vehicles. Its design, backed by expert manufacturing practices and rigorously tested performance metrics, makes it indispensable in modern automotive wiring applications. As vehicles continue to evolve with more advanced electronic systems, the demand for such reliable and efficient tapes is set to increase, highlighting their enduring relevance and necessity in the automotive sector.

Latest news

-

Versatility with Tape Electrical InsulationNewsJun.09,2025

-

Floor Marking Tapes For WareHouseNewsJun.09,2025

-

Enhance Your Projects with PVC Electrical TapesNewsJun.09,2025

-

Enhance Your Projects with Automotive Wiring Harness TapeNewsJun.09,2025

-

Enhance Your Automotive Fabric TapesNewsJun.09,2025

-

Enhance Electrical Projects with Cambric TapeNewsJun.09,2025