The Importance of Automotive Wiring Harness Tape in Modern Vehicles

In today's automotive industry, the emphasis on safety, efficiency, and durability has paved the way for innovative solutions in vehicle design and manufacturing. One critical aspect of vehicle construction that is often overlooked is the wiring harness. At the core of any vehicle's electrical system, the wiring harness is responsible for connecting various components, from the engine to infotainment systems. Given its importance, the role of automotive wiring harness tape has become increasingly vital in ensuring the integrity and longevity of these wiring systems.

Understanding Automotive Wiring Harnesses

Before delving into the specifics of wiring harness tape, it’s important to understand what a wiring harness is. Essentially, it is a bundled assembly of wires, connectors, and terminals that facilitate electrical connections throughout the vehicle. These harnesses must withstand a variety of environmental conditions, including temperature fluctuations, moisture, and mechanical stress. Inadequate protection can lead to wire abrasion, shorts, and eventual system failures, impacting the vehicle's performance and safety.

The Role of Wiring Harness Tape

Automotive wiring harness tape serves several functions that significantly enhance the reliability of wiring systems. Primarily, it is used for insulation, protection, and organization of the wires within a harness. High-quality tape can provide resistance to temperature extremes and moisture, debris, and physical damage. This is particularly crucial in vehicles, where wires are exposed to various elements and can easily be damaged.

Types of Automotive Wiring Harness Tape

There are several types of tape specifically designed for automotive applications, each offering unique properties

1. Vinyl Electrical Tape This is commonly used for insulating electrical wires and harnesses. With good stretchability and moisture resistance, it serves as an effective barrier against electrical shorts.

2. Polyester and Polyimide Tape Known for their high-temperature resistance, these tapes are often used in areas where wires come in close contact with hot engine components. They are also resistant to chemicals, making them suitable for automotive environments.

automotive wiring harness tape

3. Fabric Tape Often used for securing and bundling wires, fabric tape provides a non-slip surface that prevents wires from coming loose. Its breathable material helps to dissipate heat, reducing the risk of overheating.

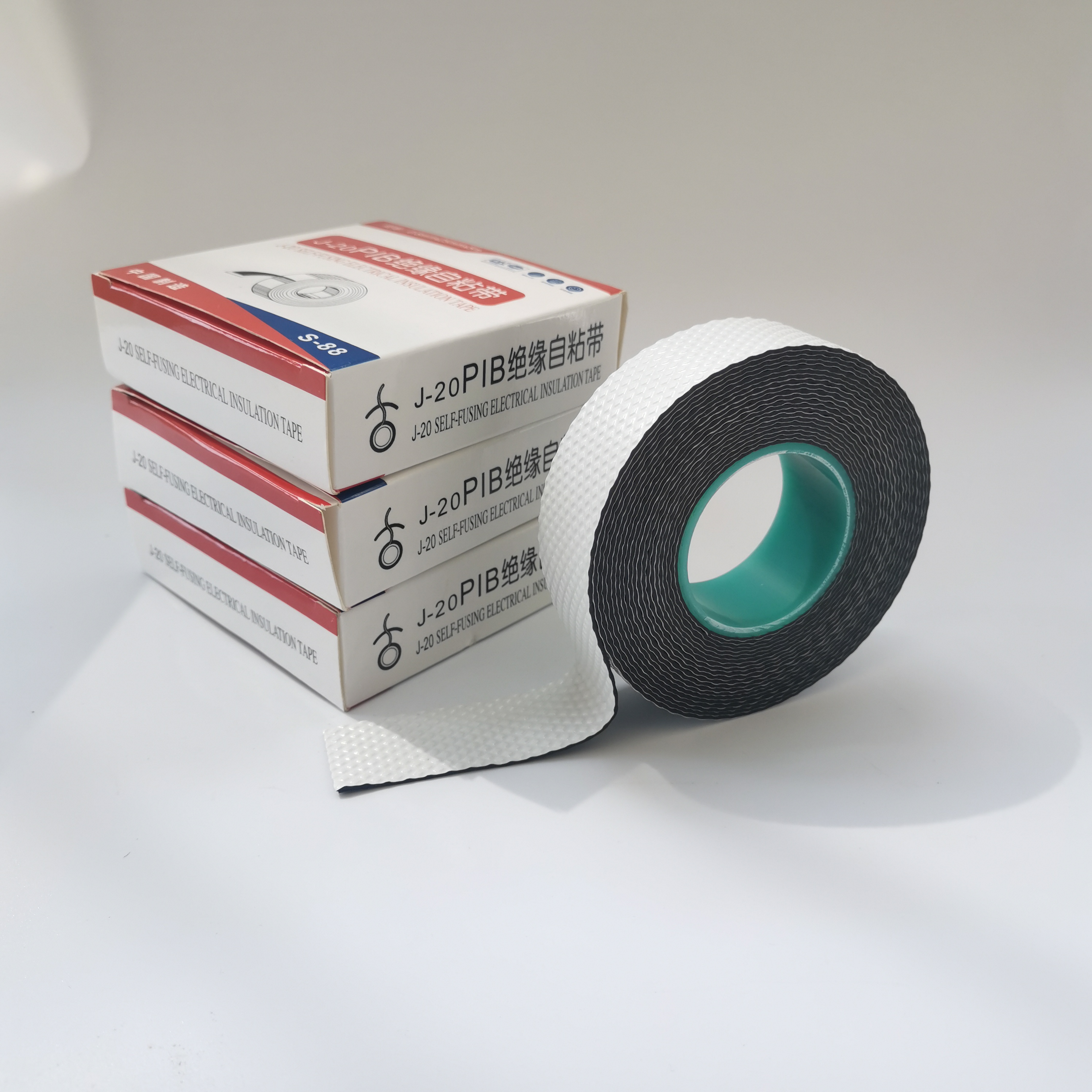

4. Self-Fusing Silicone Tape This innovative tape wraps around wires and fuses to itself upon contact, creating a waterproof and airtight seal. Its elastic properties allow it to withstand vibrations and movement without compromising the integrity of the connection.

Benefits of Using Quality Wiring Harness Tape

The use of high-quality automotive wiring harness tape can substantially enhance the performance and longevity of the wiring harness. Here are some key benefits

- Protection Against Abrasion The robust outer layer provided by the tape shields the wires from physical damage, which is particularly prevalent in high-vibration areas of the vehicle.

- Weather Resistance Automotive tape is designed to endure adverse weather conditions, protecting wires from moisture and preventing corrosion.

- Organizational Efficiency Wiring harness tape allows for neat bundling and organization, reducing visual clutter and aiding in simpler repairs and diagnostics.

- Increased Safety By providing reliable insulation, quality tape minimizes the risk of electrical shorts, significantly enhancing safety for both passengers and the vehicle itself.

Conclusion

In the realm of automotive engineering, the seemingly simple component of wiring harness tape plays an indispensable role in the overall performance and safety of vehicles. As cars increasingly incorporate advanced technologies, the requirements for reliable electrical connections are becoming more stringent. Investing in high-quality automotive wiring harness tape is not just a cost-effective solution but a critical step toward ensuring the longevity and reliability of a vehicle’s electrical systems. In a world where automotive innovations continue to evolve, attention to detail, such as securing and insulating wiring harnesses, remains crucial in the pursuit of safety and efficiency on the road.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025