The Importance of Automotive Wiring Harness Tape in Modern Vehicles

In the intricate world of automotive engineering, the wiring harness stands out as a crucial component that orchestrates the complex electronic systems of modern vehicles. As vehicles evolve to accommodate new technologies, the significance of wiring harness integrity becomes paramount. Among the materials used to protect and enhance these wirings, automotive wiring harness tape plays a vital role. This article delves into the importance of wiring harness tape in automotive applications, exploring its benefits, types, and best practices.

Understanding the Wiring Harness

A wiring harness is an assembly of wires, connectors, and terminals that transmit electrical signals throughout the vehicle. It connects various electrical and electronic components, including the engine control unit, sensors, lights, and entertainment systems. The harness ensures the efficient functioning of these systems while preventing short circuits and damages due to environmental factors.

The Role of Wiring Harness Tape

Wiring harness tape serves multiple functions that contribute to the overall performance and longevity of the wiring harness. Its primary roles include

1. Protection

The automotive environment is notoriously harsh. Components are exposed to extreme temperatures, oil, moisture, and physical abrasion. Wiring harness tape provides a protective layer that guards against these elements. By shielding the wires from heat and chemical exposure, the tape prevents deterioration and potential failures that could lead to costly repairs.

2. Organization and Bundling

Automobiles contain a vast network of wiring, which, if left unmanaged, can lead to confusion and challenges during maintenance. Wiring harness tape assists in organizing and bundling wires together. This not only facilitates a neater installation but also simplifies troubleshooting and repairs. Technicians can quickly identify and access specific wires without the risk of damaging surrounding components.

3. Insulation

Electrical insulation is critical in preventing shorts and protecting against unintended current flows. Many types of automotive wiring harness tapes come with insulation properties that enhance the safety of electrical systems. These tapes help manage electromagnetic interference (EMI), ensuring stable signal transmission, particularly in sensitive electronic systems.

Types of Automotive Wiring Harness Tape

Automotive wiring harness tape is available in various materials, each suited for different applications. Here are some common types

1. Cloth Tape

Cloth tape is a common choice for wiring harness applications. It offers excellent flexibility and conformability, making it ideal for applications where the harness needs to bend or twist. Additionally, cloth tape is typically coated with an adhesive that provides robust adhesion, ensuring it stays in place even under stress.

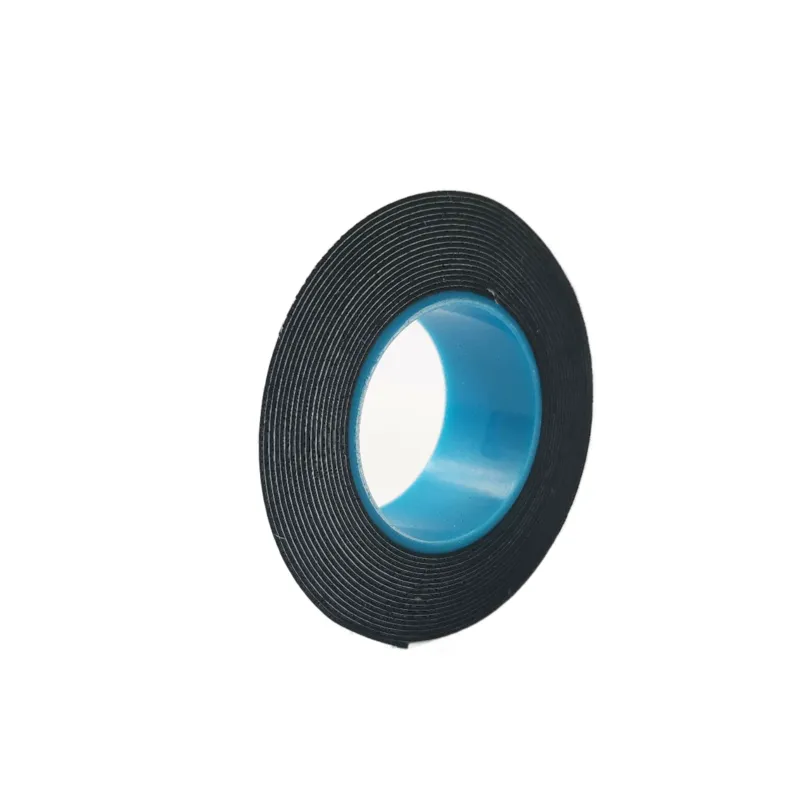

automotive wiring harness tape

2. PVC Tape

PVC (polyvinyl chloride) tape is known for its durability and resistance to moisture and chemicals. It is often used in automotive environments where exposure to oil and water is a concern. PVC tape provides good insulation properties, making it suitable for electrical applications.

3. Rubberized Tape

Rubberized tape is often utilized for applications requiring additional grip and cushioning. It is particularly beneficial in scenarios where vibration is a concern, as it can absorb shocks and reduce wear on the harness.

Best Practices for Using Wiring Harness Tape

To ensure the maximum effectiveness of automotive wiring harness tape, consider the following best practices

1. Clean the Surface

Before applying any tape, ensure the surface is clean and free of dust, oil, or debris. A clean surface allows for better adhesion and longevity of the tape.

2. Overlap Properly

When wrapping the tape around the wiring harness, ensure that each layer overlaps the previous one by about 50%. This overlap provides adequate coverage and enhances protection against environmental elements.

3. Avoid Tension

When applying the tape, avoid pulling it too tightly. Excess tension can lead to damage or deformation of the wires. Aim for a snug fit that allows for some flexibility.

4. Regular Inspections

Regularly inspect the wiring harness and tape for signs of wear, damage, or exposure to extreme elements. Early detection of potential issues can prevent costly repairs down the line.

Conclusion

As vehicles continue to integrate complex electronic systems, the role of automotive wiring harness tape becomes increasingly vital. With its protection, organization, and insulation capabilities, wiring harness tape not only enhances the longevity of the wiring harness but also contributes to the overall safety and efficacy of modern vehicles. By understanding its importance and implementing best practices in its use, automotive manufacturers and technicians can ensure the reliability and performance of their vehicles in an ever-evolving landscape.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025