Automotive Wiring Harness Wrap Ensuring Safety and Longevity

In the world of automotive engineering, ensuring the functionality and safety of vehicles is paramount. One of the critical components contributing to this safety is the automotive wiring harness. This assembly of wires, connectors, and terminals carries electrical power and signals throughout the vehicle. To optimize its performance and durability, harness wraps are of utmost importance.

Understanding the Wiring Harness

Automotive wiring harnesses are intricate networks of cables and wires that facilitate communication and power distribution among various electrical components like the engine, transmission, sensors, and infotainment systems. Given the increasing complexity of modern vehicles, the wiring harness has become more sophisticated. With the integration of advanced technologies such as electronic stability control (ESC), adaptive cruise control, and increasingly sophisticated infotainment systems, the demand for reliable and durable wiring solutions has surged.

The Role of Wiring Harness Wrap

Wiring harness wraps serve several vital functions. Primarily, they provide insulation to the wires, protecting them from physical damage, vibration, moisture, and extreme temperatures, all of which are common in a vehicle’s environment. They also help organize wiring, preventing tangles and potential shorts that could lead to failures or hazardous situations.

Different types of materials are used for harness wraps, including loom, tape, and heat-shrink tubing. Loom is often made from polyethylene or nylon and provides a lightweight protective layer that does not impede the flexibility of the wiring. Electrical tape is used widely due to its adhesive properties and resistance to abrasion and moisture. Heat-shrink tubing, which shrinks tightly around the wires when heated, offers a robust insulating solution that seals out moisture and protects against corrosion.

Benefits of Using Harness Wrap

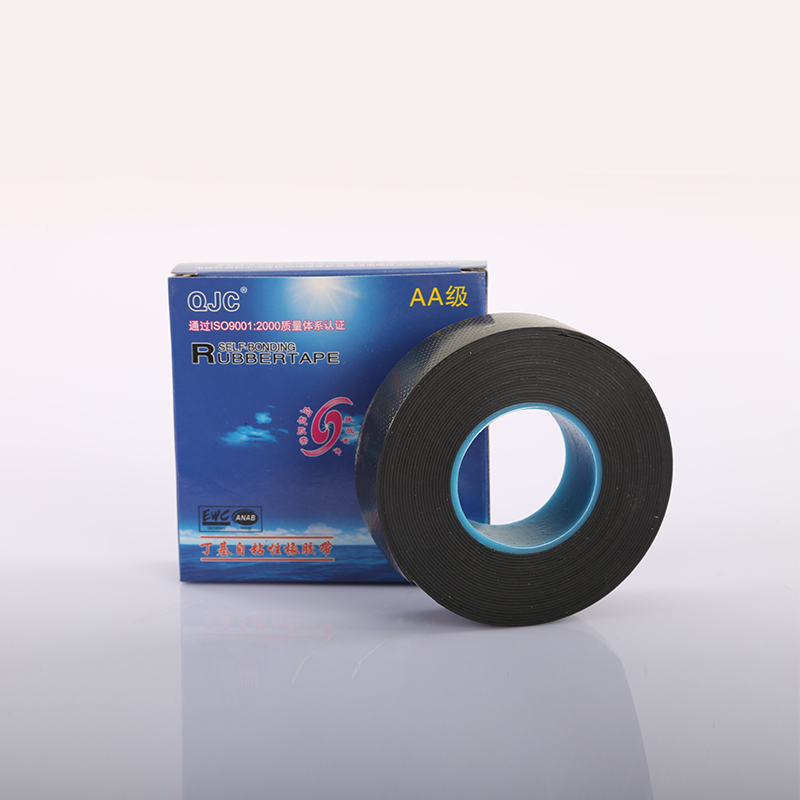

automotive wiring harness wrap

1. Protection The primary benefit of wiring harness wraps is protection. They shield the wires from abrasion, chemical exposure, and environmental factors that could lead to corrosion or wear.

2. Safety By keeping wires organized, harness wraps reduce the risk of electrical shorts or failures, which can cause critical system malfunctions or even fires. Ensuring that wires are secured and insulated is a vital part of automotive safety.

3. Ease of Maintenance A well-wrapped wiring harness allows for easier diagnosis and repair. Technicians can quickly locate and access individual wires without having to untangle extensive messes.

4. Aesthetic Appeal In some performance and custom vehicles, the appearance of the wiring is important. Harness wraps can provide a cleaner look and can be customized in terms of color and style to match the vehicle's design.

5. Noise Reduction Harness wraps can also help dampen vibrations and reduce rattling noises caused by loose wires. This level of sound insulation contributes to a quieter vehicle interior, enhancing the driving experience.

Conclusion

Automotive wiring harness wraps are an essential aspect of vehicle design and maintenance. By ensuring wires are well-organized, insulated, and protected from environmental stressors, manufacturers and technicians can significantly enhance the safety and reliability of vehicles. As automotive technology continues to evolve, the importance of effective wiring solutions will only increase, making it crucial for engineers to prioritize quality harness wraps in their designs. Whether you're a manufacturer, technician, or an automotive enthusiast, understanding and utilizing the right wiring harness wrap will lead to safer, more efficient vehicles for everyone on the road.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025