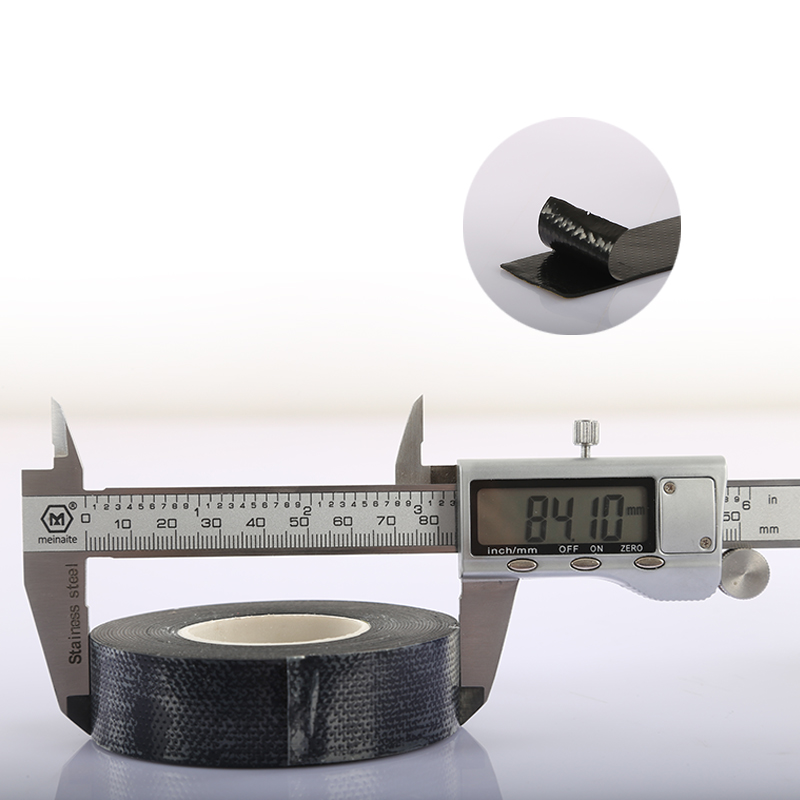

automotive wiring harness tape

Back to list

Feb . 03, 2025 02:49

Automotive wiring tape plays a crucial role in the seamless functioning of vehicles by ensuring the integrity and safety of electrical systems. When delving into the intricacies of automotive wiring, using high-quality tape is essential for maintaining durability and performance. This article explores the unmatched experience and expertise underlying automotive wiring tape, providing an authoritative guide on choosing the right product for optimal trustworthiness and reliability.

Trustworthiness in automotive wiring tapes is built on a foundation of transparency and consistent quality feedback from end-users. Consumers often rely on reviews and testimonials to find reliable, high-performing products. Anonymously gathered feedback regarding the longevity and reliability of the tape under harsh conditions reinforces trustworthiness. Automotive tapes produced by reputable manufacturers maintain a commitment to producing consistent quality, supported by detailed data sheets that inform consumers about the tape’s resistance capabilities, adhesive strength, and thermal endurance. Brands that supply this level of detailed information gain consumer trust by demonstrating accountability and transparency. Moreover, proper installation practices are paramount to the trustworthiness of automotive wiring tape. Incorrect application can lead to unintended exposure to elements or loss of adhesive properties, undermining the tape's effectiveness. Detailed user instructions, including temperature guidelines for application and surface pre-treatment, promote successful results. Professionals well-versed in the field often recommend specific installation techniques based on their intimate understanding of how best to utilize the tape in various wiring scenarios. In summary, selecting automotive wiring tape involves evaluating products through the lens of experience, expertise, authority, and trustworthiness. By prioritizing products backed by proven efficacy over time, consumers can ensure safer and more efficient automotive electrical systems. A choice informed by seasoned knowledge and real-world application further reassures that the electrical integrity of one's vehicle is upheld, facilitating smooth functionality and extending the lifespan of automotive components.

Trustworthiness in automotive wiring tapes is built on a foundation of transparency and consistent quality feedback from end-users. Consumers often rely on reviews and testimonials to find reliable, high-performing products. Anonymously gathered feedback regarding the longevity and reliability of the tape under harsh conditions reinforces trustworthiness. Automotive tapes produced by reputable manufacturers maintain a commitment to producing consistent quality, supported by detailed data sheets that inform consumers about the tape’s resistance capabilities, adhesive strength, and thermal endurance. Brands that supply this level of detailed information gain consumer trust by demonstrating accountability and transparency. Moreover, proper installation practices are paramount to the trustworthiness of automotive wiring tape. Incorrect application can lead to unintended exposure to elements or loss of adhesive properties, undermining the tape's effectiveness. Detailed user instructions, including temperature guidelines for application and surface pre-treatment, promote successful results. Professionals well-versed in the field often recommend specific installation techniques based on their intimate understanding of how best to utilize the tape in various wiring scenarios. In summary, selecting automotive wiring tape involves evaluating products through the lens of experience, expertise, authority, and trustworthiness. By prioritizing products backed by proven efficacy over time, consumers can ensure safer and more efficient automotive electrical systems. A choice informed by seasoned knowledge and real-world application further reassures that the electrical integrity of one's vehicle is upheld, facilitating smooth functionality and extending the lifespan of automotive components.

Next:

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025