The Role of Butyl Rubber Strips in Various Applications

Butyl rubber strips are an essential component in various industries due to their unique properties and versatility. Butyl rubber, a synthetic rubber composed of isobutylene and isoprene, is renowned for its excellent impermeability to gases and moisture, making it ideal for applications where sealing and insulation are critical.

Properties of Butyl Rubber

Butyl rubber strips possess several key characteristics that make them suitable for a wide range of applications. First and foremost, their low permeability to gases is one of their most significant advantages. This makes them the material of choice for sealing applications, such as in tire inner linings, where preventing air leakage is crucial. Additionally, butyl rubber exhibits exceptional resistance to aging, weathering, and UV radiation, ensuring durability and longevity in outdoor applications.

Another notable property is its low temperature flexibility. Butyl rubber remains pliable even in cold weather, providing consistent performance in varying environmental conditions. Moreover, it has good chemical resistance, making it suitable for environments where exposure to oils, chemicals, and solvents may occur.

Applications of Butyl Rubber Strips

1. Automotive Industry Butyl rubber strips are commonly used in the automotive sector for sealing and insulating applications. They are utilized in door seals, window seals, and gaskets, providing effective barriers against water, dust, and noise. With their ability to withstand extreme temperatures and environmental conditions, these strips play a crucial role in enhancing vehicle longevity and performance.

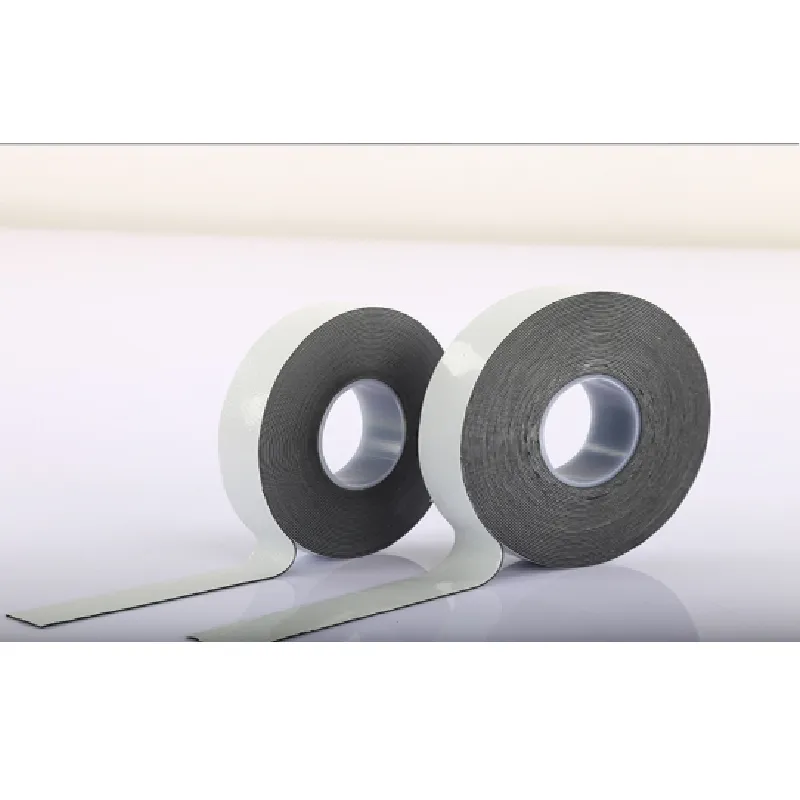

butyl rubber strip

2. Construction In the construction industry, butyl rubber strips are employed for waterproofing and sealing joints. They are particularly beneficial in roofing applications, where they help prevent leaks and water damage. The flexibility and adhesive properties of butyl rubber strips make them ideal for sealing around windows, doors, and other openings, ensuring energy efficiency by reducing air infiltration.

3. Electrical Insulation Butyl rubber’s excellent electrical insulating properties make it suitable for various electrical applications. It is used in cable insulations and protective coverings, safeguarding electrical components from moisture and contaminants. These strips provide both mechanical protection and electrical insulation, making them essential in maintaining the reliability of electrical systems.

4. Medical Applications The biocompatibility of butyl rubber makes it suitable for medical applications as well. It is used in the manufacturing of seals and gaskets for medical devices, ensuring sterile environments and preventing contamination. Its impermeability to gases and moisture further enhances its utility in critical medical applications.

5. Aerospace The aerospace industry also benefits from the properties of butyl rubber strips. They are used for sealing and insulating aerospace components, where performance under extreme conditions is crucial. The lightweight nature of butyl rubber contributes to overall weight reduction in aircraft, making it a valuable material in aerospace engineering.

Conclusion

In summary, butyl rubber strips are a vital component in numerous industries due to their unique attributes, including low permeability, chemical resistance, and durability. Their applications range from automotive and construction to electrical insulation, medical devices, and aerospace, showcasing their versatility and importance across sectors. As technology continues to evolve, the demand for high-performance materials like butyl rubber is expected to grow, making it a topic of ongoing interest and innovation. The continued development and application of butyl rubber strips will likely provide solutions to emerging challenges in various fields, ensuring their relevance in the years to come.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025