The Growing Importance of Butyl Rubber Tape A Look at Suppliers

In the ever-evolving landscape of industrial materials, butyl rubber tape has emerged as a pivotal player due to its exceptional adhesive properties and versatility. Manufacturers and suppliers of butyl rubber tape are now at the forefront of addressing diverse applications across various industries, including construction, automotive, and aerospace. This article aims to explore the characteristics of butyl rubber tape, its applications, and the critical role of suppliers in ensuring quality and availability.

What is Butyl Rubber Tape?

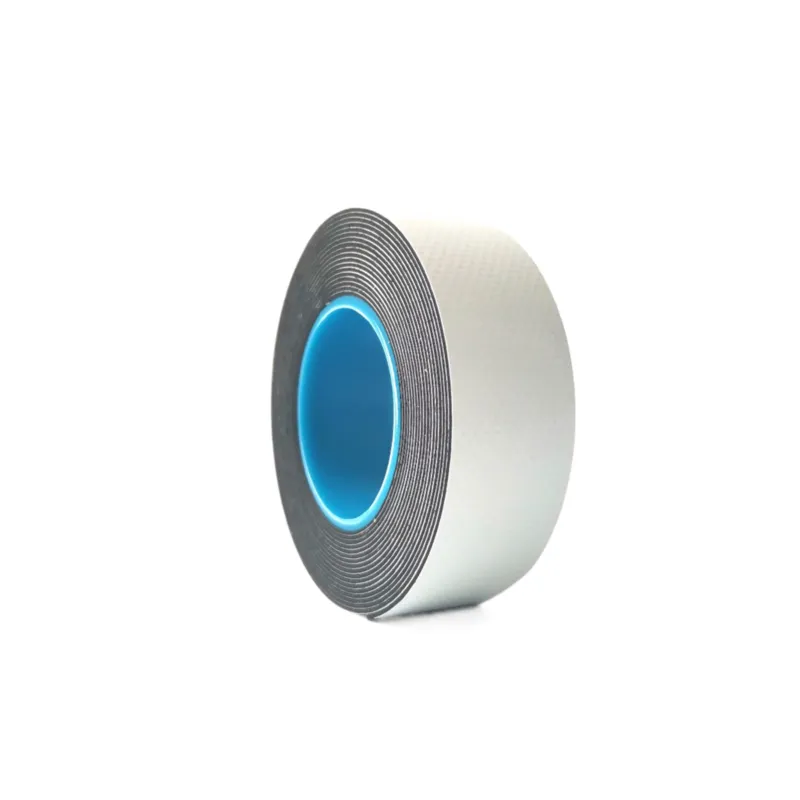

Butyl rubber tape is a type of tape made from butyl rubber, a synthetic rubber known for its excellent airtightness, weather resistance, and flexibility. This material's properties make it ideal for sealing, insulating, and bonding applications. The tape typically features a thick, sticky adhesive backing that adheres well to various surfaces, including metal, wood, glass, and plastic.

One of the standout features of butyl rubber tape is its ability to maintain its integrity in extreme temperatures, making it suitable for both hot and cold environments. Moreover, it is resistant to UV light and moisture, ensuring long-lasting performance in outdoor settings.

Applications of Butyl Rubber Tape

The versatility of butyl rubber tape means it can be used in several industries. Here are a few notable applications

1. Construction Butyl rubber tape is extensively used in the construction industry for sealing roofs, windows, and doors. Its water-resistant properties protect buildings from leaks and drafts, enhancing energy efficiency and comfort.

2. Automotive In the automotive sector, butyl rubber tape is employed for body sealing, vibration dampening, and insulation. Its ability to withstand temperature fluctuations makes it ideal for use in vehicles exposed to various environmental conditions.

3. Aerospace The aerospace industry utilizes butyl rubber tape for bonding and sealing components in aircraft. Its lightweight nature and resistance to harsh conditions make it suitable for critical applications where reliability is essential.

butyl rubber tape supplier

4. Electrical In electrical applications, butyl rubber tape provides insulation and moisture protection for wires and connectors. It contributes to safety and efficiency by preventing short circuits and corrosion.

The Role of Suppliers

The importance of reliable suppliers of butyl rubber tape cannot be overstated. Suppliers play a crucial role in ensuring that high-quality materials are available to manufacturers and end-users. Here are several key factors to consider when selecting a butyl rubber tape supplier

1. Quality Assurance A reputable supplier should adhere to industry standards and regulations. They should provide documentation, such as certifications, that guarantee the quality and safety of their products.

2. Variety and Customization Suppliers that offer a range of butyl rubber tape options, including different thicknesses, widths, and adhesive strengths, can better meet the specific needs of various industries. Customizable solutions can enhance the efficiency of applications, leading to better end results.

3. Technical Support Suppliers with knowledgeable staff who can provide technical assistance and advice can be invaluable. They can help clients choose the right tape for their specific applications, ensuring optimal performance and results.

4. Sustainability Practices As industries shift towards more sustainable practices, suppliers that prioritize environmentally friendly materials and manufacturing processes are increasingly favored. Choosing such suppliers can help companies align with eco-conscious initiatives.

Conclusion

In summary, butyl rubber tape is an essential material that supports a wide range of applications across various industries. Suppliers of butyl rubber tape not only provide the product but also ensure quality, variety, and support, making them indispensable partners in the manufacturing and application processes. As demand for butyl rubber tape continues to grow, the role of suppliers will become even more critical in fostering innovation and meeting the evolving needs of their clients.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025