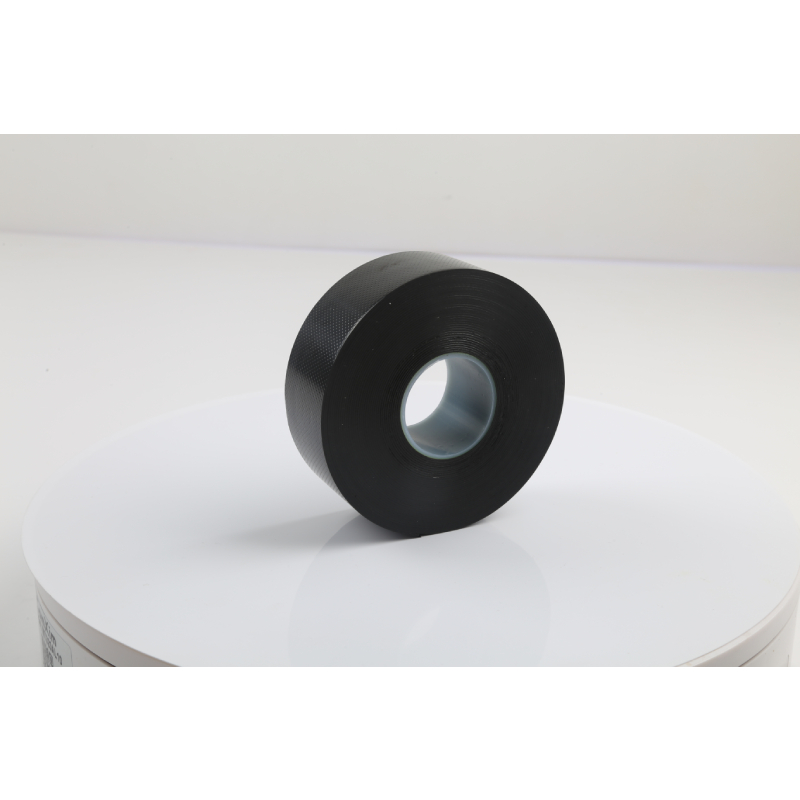

Butyl Rubber Tape

Back to list

Feb . 14, 2025 19:33

Butyl rubber waterproofing has rapidly become a cornerstone in the realm of construction and infrastructure development, owing to its exceptional durability and versatility. This synthetic rubber is renowned for its unique molecular structure that offers superior waterproofing capabilities, making it an indispensable material for both new constructions and restoration projects. As a material that exemplifies advanced engineering, butyl rubber embodies the characteristics that construction professionals consistently seek reliability, longevity, and efficiency.

In terms of authoritativeness, butyl rubber has been the subject of numerous studies and endorsements by leading engineering bodies and construction authorities worldwide. Its use spans across continents, with building codes in various regions recognizing its efficacy. For instance, in areas susceptible to extreme weather events such as heavy rainfall or snow, butyl rubber emerges as a recommended solution for waterproofing needs. Furthermore, it is often selected for critical infrastructure projects, such as tunnels and bridges, where failure is not an option. Buildings certified for resilience and sustainability frequently opt for butyl rubber, reinforcing its standing as a trusted material. Lastly, the trustworthiness of butyl rubber is cemented by its consistent performance in real-world applications. Testimonials from architects and engineers highlight its capacity to maintain integrity over decades. Unlike alternatives that may degrade or lose elasticity, butyl rubber remains steadfast, supporting structures through their lifecycle. It is this reliability that assures stakeholders—from construction teams to investors—of a project's enduring quality. Manufacturers also provide detailed warranties, evidence of their confidence in the product's capabilities and durability. In conclusion, butyl rubber waterproofing stands out as a superior choice for any construction project aiming for excellence in quality and performance. Its adaptability, coupled with advanced formulation, positions it as a forward-thinking solution in an ever-evolving industry. As more construction projects strive to meet rigorous standards of efficiency and sustainability, integrating butyl rubber into waterproofing strategies is not merely a choice but a necessity for future-ready buildings.

In terms of authoritativeness, butyl rubber has been the subject of numerous studies and endorsements by leading engineering bodies and construction authorities worldwide. Its use spans across continents, with building codes in various regions recognizing its efficacy. For instance, in areas susceptible to extreme weather events such as heavy rainfall or snow, butyl rubber emerges as a recommended solution for waterproofing needs. Furthermore, it is often selected for critical infrastructure projects, such as tunnels and bridges, where failure is not an option. Buildings certified for resilience and sustainability frequently opt for butyl rubber, reinforcing its standing as a trusted material. Lastly, the trustworthiness of butyl rubber is cemented by its consistent performance in real-world applications. Testimonials from architects and engineers highlight its capacity to maintain integrity over decades. Unlike alternatives that may degrade or lose elasticity, butyl rubber remains steadfast, supporting structures through their lifecycle. It is this reliability that assures stakeholders—from construction teams to investors—of a project's enduring quality. Manufacturers also provide detailed warranties, evidence of their confidence in the product's capabilities and durability. In conclusion, butyl rubber waterproofing stands out as a superior choice for any construction project aiming for excellence in quality and performance. Its adaptability, coupled with advanced formulation, positions it as a forward-thinking solution in an ever-evolving industry. As more construction projects strive to meet rigorous standards of efficiency and sustainability, integrating butyl rubber into waterproofing strategies is not merely a choice but a necessity for future-ready buildings.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025