The Evolution and Utility of Car Loom Tape

In the intricate world of automotive engineering and repair, few components are as underestimated yet crucial as loom tape. This versatile product often goes unnoticed, but its applications in the automotive industry are integral to ensuring longevity and reliability in vehicle operations. Car loom tape, designed specifically for the protection and organization of wiring harnesses, offers myriad benefits that are worth exploring.

Understanding Car Loom Tape

Car loom tape is a specialized adhesive tape primarily used for bundling and insulating electrical wires in automotive applications. Unlike traditional electrical tape, loom tape is generally non-adhesive on one side, allowing for easy application and removal without leaving sticky residues behind. It is typically made from durable materials such as cotton, PVC, or polyester, making it resilient against heat, moisture, abrasion, and other environmental factors.

Importance of Loom Tape in Automotive Wiring

The automotive wiring system is essential for the functioning of various vehicle components, from ignition systems to lighting. Bundled wiring can become tangled or exposed over time, leading to potential short circuits, electrical failures, and even electrical fires. This is where car loom tape plays a critical role.

1. Protection Car loom tape provides a protective layer that guards wires from physical damage caused by vibration, friction, and environmental factors. It helps shield the wiring from abrasions and impact, particularly in areas prone to wear, such as wheel wells and engine compartments.

2. Organization In the automotive repair and manufacturing industries, cleanliness and organization are pivotal for efficiency. Loom tape helps keep wiring harnesses neatly bundled, reducing the chances of tangling and making inspections easier. A tidy wiring system not only looks professional but also simplifies troubleshooting and repairs.

3. Insulation Loom tape offers essential insulation for exposed wires. Although it is not designed to replace traditional electrical tape, when used in conjunction, it enhances the overall insulation of the wiring, reducing the risk of shorts and enhancing safety.

4. Heat Resistance Cars often deal with extreme temperatures, especially around the engine area. Loom tape is engineered to withstand these conditions without degrading or losing its integrity. This thermal resistance is crucial for maintaining the performance of the wiring over time.

Application in the Automotive Industry

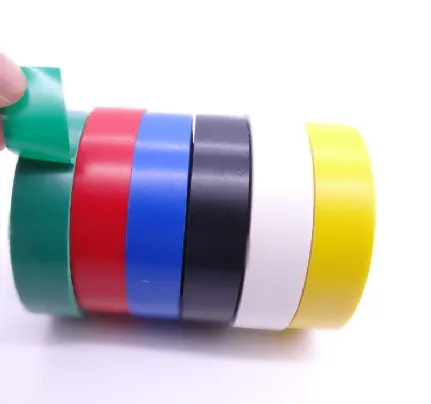

car loom tape

Loom tape can be found in numerous applications across the automotive industry. Whether in the manufacturing of new vehicles or in repair shops for vehicle maintenance, the tape is employed wherever wiring needs to be secured and managed.

During vehicle assembly, loom tape is used to bind wiring harnesses to ensure they are securely positioned away from moving parts. This minimizes the risk of wear and tear during normal operations. Furthermore, during repairs, mechanics often utilize loom tape to re-secure wires after repairs or modifications, ensuring that everything remains organized and functional.

Choosing the Right Loom Tape

When selecting loom tape for automotive purposes, several factors need to be considered

- Material Different materials cater to different needs. Cotton loom tape, known for its durability and softness, is ideal for high-temperature environments, while PVC is more flexible and resistant to moisture.

- Width and Thickness Depending on the bulk of the wires being bundled, the width and thickness of the loom tape can vary. It’s important to choose a size that provides adequate coverage without being overly cumbersome.

- Color While black is the most common color for loom tape, it is also available in various shades. Color-coding can be beneficial for identification purposes, especially in complex wiring systems.

Conclusion

Though often overlooked, car loom tape is an indispensable component in the automotive industry. Its protective, organizational, and insulative properties are vital for maintaining the integrity of automotive wiring systems. As the automotive landscape continues to evolve with advancements in technology, the role of loom tape remains pivotal. Both manufacturers and repair professionals must recognize the importance of this simple yet effective tool, ensuring safety and efficiency in their operations.

By understanding the significance of car loom tape, vehicle owners and professionals alike can appreciate the meticulous attention to detail required in automotive wiring systems. After all, a well-organized and protected wiring harness is a key factor in the overall performance and longevity of any vehicle.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025