Understanding Car Wiring Loom Tape Essential for Vehicle Maintenance

When it comes to automobile maintenance, one of the most overlooked aspects is the management of wiring systems. In modern vehicles, the complexity of electrical systems has increased dramatically, making the proper handling and protection of wires essential for both safety and functionality. This is where car wiring loom tape comes into play.

What is Wiring Loom Tape?

Wiring loom tape, also known as harness tape or self-adhesive tape, is a specialized type of tape used to bundle and organize wiring within a vehicle. It is typically made from a durable, insulating material that can withstand high temperatures, moisture, and abrasion. The purpose of this tape is not only to keep wires neatly organized but also to protect them from wear and tear, reducing the risk of electrical failures and short circuits.

Benefits of Using Wiring Loom Tape

1. Protection from Damage One of the primary benefits of wiring loom tape is its ability to protect wires from physical damage. Wires that are exposed to friction, moisture, or heat can deteriorate over time. By using loom tape, you can significantly extend the lifespan of your vehicle’s wiring.

2. Improved Organization Using loom tape helps to bundle wires together, making it easier to manage and identify them. This is particularly beneficial during maintenance or repairs when technicians need to access specific wires quickly. A well-organized wiring system also reduces the chances of accidental cuts or disconnects.

3. Enhanced Aesthetic Appeal A tangle of exposed wires can make the engine bay or interior of a vehicle look cluttered and unprofessional. Loom tape provides a neat finish, giving a cleaner look that is more pleasing to the eye. For automotive enthusiasts, this aspect is often just as important as functionality.

4. Noise Reduction Loose wires can rattle against each other or parts of the vehicle, leading to annoying noises while driving. By securing them with loom tape, you can minimize these sounds and contribute to a quieter cabin.

5. Insulation and Electrical Safety The insulation properties of loom tape help to prevent electrical shorts, which can lead to a variety of problems, from blown fuses to fire hazards. By encasing wires properly, the risk of stray currents is greatly reduced.

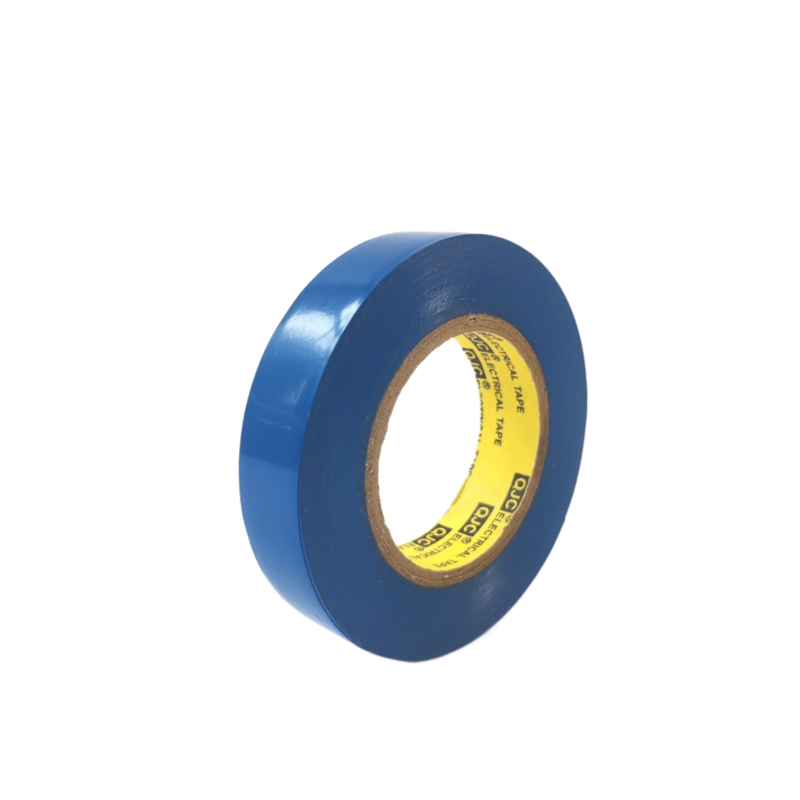

car wiring loom tape

How to Use Wiring Loom Tape

Using wiring loom tape is a straightforward process, but it is essential to follow a few best practices for maximum effectiveness

1. Clean the Area Before applying the tape, ensure that the surface of the wires is clean and free of dust or oils. This will help the tape to adhere better.

2. Bundle Wires Gather the wires you want to bundle together. If they are not already organized, group them according to function or destination to prevent confusion in the future.

3. Apply the Tape Start winding the tape around the bundle of wires, overlapping each layer slightly. Ensure that you are applying enough pressure to make a secure bond, but avoid wrapping too tightly, which can damage the wires.

4. Cut and Secure Once you reach the end of the wire bundle, cut the tape and press the end firmly against the previous layer to secure it.

5. Regular Inspections Periodically check the taped areas for signs of wear or damage. Re-tape as necessary to maintain protection.

Conclusion

In conclusion, car wiring loom tape is an invaluable tool for anyone involved in vehicle maintenance, from professional mechanics to DIY enthusiasts. Its ability to protect, organize, and enhance the appearance of vehicle wiring makes it an essential component of automotive care. By investing in quality wiring loom tape and employing it correctly, you can ensure that your vehicle remains safe, functional, and looking great for years to come. Whether performing regular maintenance or tackling repairs, don't underestimate the importance of properly managing your vehicle's wiring systems.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025