The Importance of Heat Proof Electrical Tape

In the realm of electrical installations and repairs, selecting the right materials is crucial for both safety and efficiency. One such essential component is heat proof electrical tape. Often overlooked, this specialized tape provides numerous benefits that make it an indispensable tool for electricians, engineers, and DIY enthusiasts alike.

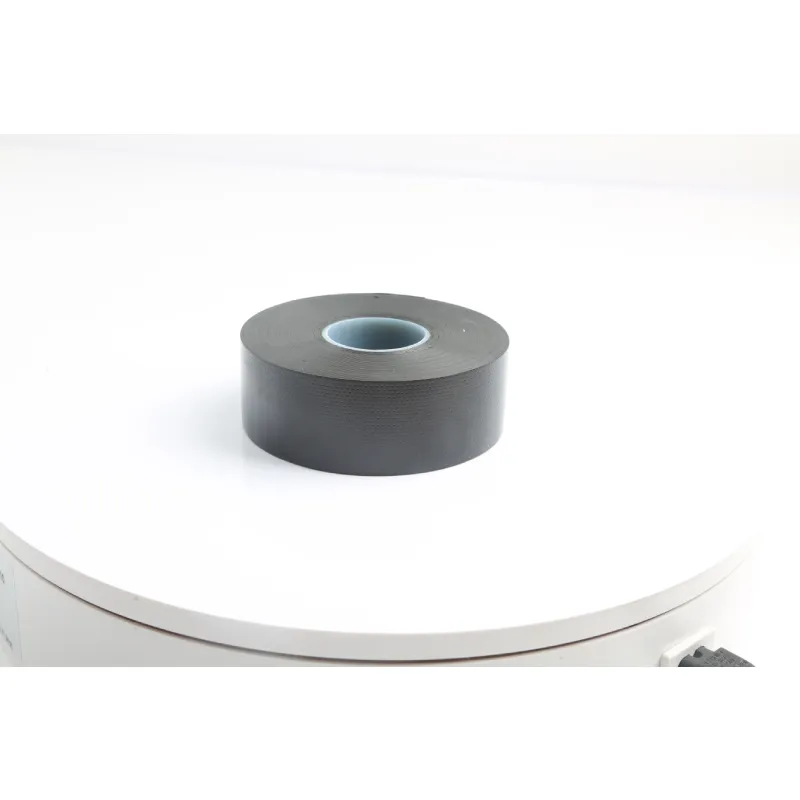

What is Heat Proof Electrical Tape?

Heat proof electrical tape is a type of insulation tape designed to withstand high temperatures without losing its adhesive properties or structural integrity. Made from materials like vinyl, silicone, or fiberglass, this tape can endure extreme conditions, often withstanding temperatures ranging from -10°C to over 200°C. This remarkable heat resistance makes it ideal for various applications, particularly in environments where heat is a significant concern.

Applications in Electrical Work

Electrical systems generate heat during operation. Components like motors, transformers, and circuit boards can develop hot spots that, if not managed properly, may lead to equipment failure or even fire hazards. Heat proof electrical tape serves as a protective layer, ensuring that electrical components are insulated from the potentially detrimental effects of heat.

One common usage is in the automotive industry, where electrical connections are often exposed to extreme heat from engines. Heat proof electrical tape is used to wrap around wiring and connections, providing insulation and protection from high temperatures and moisture, thereby preventing degradation and short circuits.

Additionally, this tape is also employed in electrical appliances, HVAC systems, and industrial machinery. In these settings, it protects wires and components from heat damage, contributing to the longevity and reliability of the equipment.

heat proof electrical tape

Benefits of Using Heat Proof Electrical Tape

1. Safety Safety is paramount in electrical work. Using heat resistant tape helps to prevent electrical fires and short circuits caused by thermal breakdown. By properly insulating wiring with heat proof tape, electricians can ensure that systems operate safely and efficiently.

2. Durability Heat proof electrical tape is designed to last. It is resistant to wear, moisture, and chemicals, ensuring that it maintains its properties under harsh conditions. This durability reduces the need for frequent repairs and replacements, saving time and money over the long term.

3. Versatility This tape is incredibly versatile. It can be used in various applications beyond electrical work, including plumbing, automotive repair, and general maintenance. Its ability to perform under high-temperature conditions makes it a go-to choice across industries.

4. Ease of Use Heat proof electrical tape is user-friendly. It can be easily cut, applied, and removed as needed. This simplicity allows both professionals and amateurs to accomplish tasks efficiently, ensuring that projects are completed on time without compromising quality.

5. Cost-Effective Solution While the initial investment in heat proof electrical tape may be slightly higher than regular tape, the benefits it provides can lead to significant cost savings. By preventing damage and reducing repair needs, it proves to be a cost-effective solution in the long run.

Conclusion

In conclusion, heat proof electrical tape is a vital component in any electrical toolbox. Its ability to withstand high temperatures while providing excellent insulation makes it ideal for various applications. Whether in automotive, HVAC, or general electrical work, investing in high-quality heat proof electrical tape is essential for ensuring safety, durability, and efficiency. By understanding the importance and benefits of this tape, electricians and engineers can enhance the reliability of their work and contribute to safer operating environments.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025