Understanding Electrical Harness Tape A Crucial Component in Wiring Systems

In today’s technologically advanced world, the functionality and reliability of electrical systems are paramount. One often overlooked yet crucial component in the assembly and protection of wiring systems is electrical harness tape. This specialized tape plays a significant role in ensuring the safety, durability, and efficiency of electrical harnesses in various applications, including automotive, aerospace, and industrial machinery.

What is Electrical Harness Tape?

Electrical harness tape is a type of adhesive tape used to bind, insulate, and protect electrical wires and cables. It is designed to withstand various environmental conditions, making it suitable for both indoor and outdoor applications. The tape is primarily made from materials such as PVC (polyvinyl chloride), cloth, and in some cases, specialized adhesives that ensure a strong bond without compromising flexibility.

Key Features and Benefits

1. Insulation and Protection One of the primary functions of electrical harness tape is to provide electrical insulation. This ensures that wires within an electrical harness do not short-circuit or cause interference. Additionally, the tape protects against physical damage from abrasion, UV radiation, moisture, and chemicals, extending the lifespan of the wiring.

2. Improved Organization Electrical harness tape aids in organizing wires into neat bundles. This organization makes installation easier and enhances the overall aesthetics of the wiring system. A clean, well-organized harness minimizes the risk of wear and tear on the cables while facilitating easier maintenance or repairs if needed.

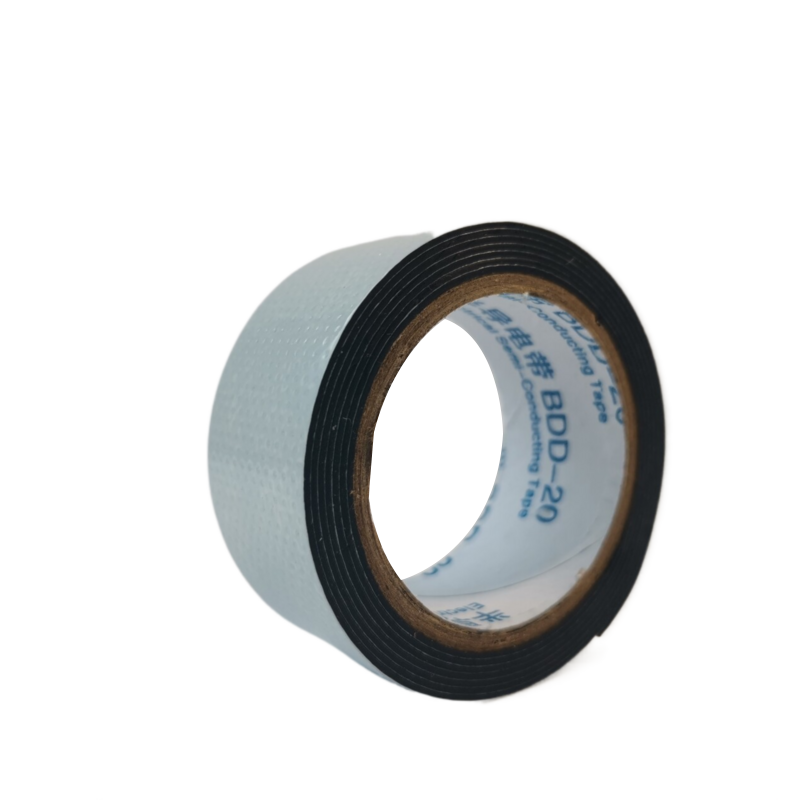

electrical harness tape

3. Heat Resistance High-quality electrical harness tape is often designed to resist high temperatures. This is particularly important in automotive and aerospace applications where wires can be exposed to extreme heat from engines or electronic components. Heat-resistant tape helps to maintain the integrity of the insulation and prevents breakdown over time.

4. Noise Reduction The application of electrical harness tape can also help to dampen vibrations and reduce noise. This is especially beneficial in automotive applications, where reducing cabin noise can significantly enhance comfort. The tape absorbs sound and minimizes rattles from loose wires or cables.

5. Ease of Application Most electrical harness tapes are designed for easy application. They often come in rolls that can be easily cut to size, and the adhesive backing allows for quick and efficient wrapping around wires. This ease of use can significantly reduce labor time during the installation process.

Applications of Electrical Harness Tape

Electrical harness tape is used in a myriad of industries. In the automotive sector, it ensures that wiring for lights, sensors, and power systems remains organized and functional. In aerospace, the tape is crucial for protecting critical wiring that controls navigation and communication systems. Industrial machinery also utilizes electrical harness tape to ensure safety and reliability in power systems, reducing the risks of downtime due to electrical issues.

Conclusion

While it may seem like a simple accessory in the world of electrical systems, electrical harness tape plays a critical role in enhancing the performance and safety of electrical wiring. From insulation and protection to organization and noise reduction, the benefits of this versatile tape are undeniable. As technology continues to evolve, the significance of reliable electrical systems will only increase, and so will the importance of components like electrical harness tape. For industries that depend on robust electrical wiring, investing in high-quality harness tape is not just a necessity; it is a measure of ensuring the long-term performance and safety of their systems.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025