Understanding Electrical Harness Tape An Essential Component in the Automotive and Electronics Industries

In today's rapidly advancing technological landscape, the importance of efficient and reliable electrical systems cannot be overstated. At the heart of these systems lies a paramount component known as electrical harness tape. Whether in automotive applications, aerospace engineering, or consumer electronics, this specialized tape plays a crucial role in ensuring the safety, functionality, and longevity of electrical wiring and harnesses.

What is Electrical Harness Tape?

Electrical harness tape is a type of adhesive tape specifically designed for bundling, insulating, and protecting wiring harnesses. These harnesses consist of multiple wires bundled together, which connect various components within an electrical system. The primary function of the tape is to prevent wire abrasion, moisture ingress, and electromagnetic interference, which can lead to system failures or malfunctions.

Properties and Advantages

The composition of electrical harness tape varies, typically made from a variety of materials including PVC, nylon, and cloth. Depending on the specific application, harness tape can come in various thicknesses, lengths, and widths, allowing for flexibility in usage. Some of the key properties that make electrical harness tape indispensable include

- Insulation The tape provides excellent electrical insulation, reducing the risk of short circuits and electrical failures. This characteristic ensures that the tape can withstand high voltages and temperatures, making it suitable for use in harsh environments.

- Durability Harness tape is designed to be robust and resistant to wear and tear. This durability protects the underlying wires from damage caused by friction, extreme temperatures, and exposure to chemicals.

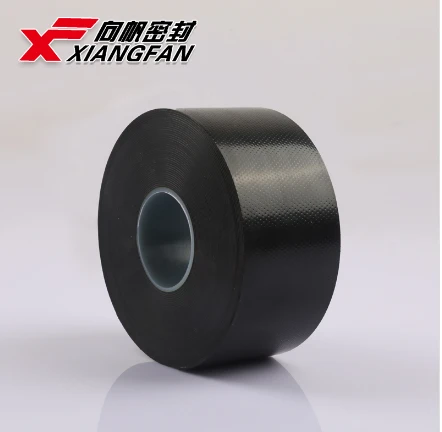

electrical harness tape

- Conformability The flexible nature of the tape allows it to wrap snugly around wires and harnesses, ensuring a tight fit that reduces the risk of movement and abrasion.

- Moisture Resistance Many electrical harness tapes are treated to repel moisture, which aids in preventing corrosion and short circuits that can arise from exposure to water or other liquids.

Applications in Various Industries

Electrical harness tape is extensively used in a variety of sectors. In the automotive industry, for instance, it is employed to protect and bundle wires within vehicles, ensuring that electrical components such as lights, sensors, and control units operate efficiently and safely. The automotive environment is particularly challenging due to vibrations, temperature fluctuations, and exposure to various chemicals, making harness tape an invaluable resource.

In the aerospace sector, the need for lightweight, durable, and fire-resistant materials is critical. Electrical harness tape must meet stringent safety standards while effectively securing wiring systems critical for aircraft operation. Similarly, consumer electronics manufacturers rely on harness tape to safeguard wires within devices where space is limited and reliability is paramount.

Conclusion

In summary, electrical harness tape is a small but mighty component that plays an integral role in safeguarding the functionality and reliability of electrical systems across various industries. Its unique properties, including insulation, durability, conformability, and moisture resistance, ensure that wiring harnesses remain protected in demanding environments. As technology continues to evolve and electrical systems become increasingly complex, the demand for reliable electrical harness tape will only grow. By understanding the importance and application of this essential material, industries can continue to innovate and develop safer, more efficient electrical solutions for the future.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025