The Market for Electrical Insulation Tape An Overview of Prices and Trends

Electrical insulation tape is a fundamental component in various industries, including electrical engineering, construction, manufacturing, and automotive. Its primary purpose is to provide electrical insulation, prevent short circuits, and secure electrical components. As the demand for high-quality electrical insulation tape increases, understanding its pricing and market dynamics becomes increasingly important for consumers and businesses alike.

Factors Influencing Prices

1. Material Composition The price of electrical insulation tape can vary significantly depending on the materials used in its production. Common materials include PVC (polyvinyl chloride), rubber, and fiberglass. PVC tape is the most widely used due to its cost-effectiveness and excellent insulating properties. However, specialty tapes, such as those made from silicone or heavy-duty rubber, can command higher prices due to their enhanced performance characteristics.

2. Adhesive Quality The type of adhesive utilized also affects the price of insulation tape. High-performance adhesives that can withstand extreme temperatures or provide better adhesion in challenging environments will typically increase the cost of the tape. This is vital for applications that require reliability and durability.

3. Temperature Rating Electrical insulation tapes are available in a variety of temperature ratings, from standard to high-temperature options. Tapes designed to withstand higher temperatures or harsh environments often come at a premium. For industries such as automotive and aerospace, where thermal management is critical, investing in higher-rated insulation tape is necessary despite the added cost.

4. Brand and Manufacturer Brand reputation can play a significant role in pricing. Established brands may price their products higher due to perceived quality and reliability. Conversely, lesser-known brands might offer competitive pricing but could compromise on material quality and performance.

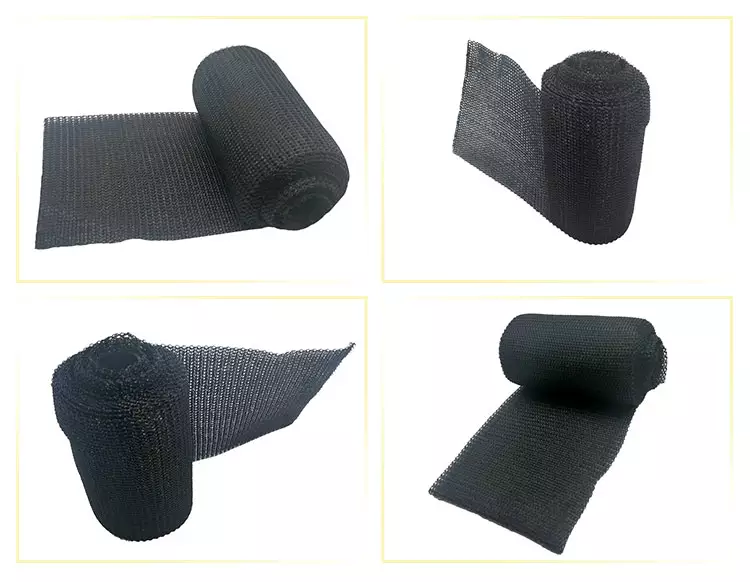

electrical insulation tape price

5. Market Demand and Trends Supply chain fluctuations, changes in consumer demand, and economic conditions can impact prices. For instance, during periods of economic growth, demand for electrical insulation tape may increase in construction and manufacturing sectors, driving prices up. Conversely, during economic downturns, prices may stabilize or decrease due to reduced demand.

Price Range

The price of electrical insulation tape commonly ranges from $0.10 to $2.00 per roll, depending on the factors mentioned above. Average rolls of standard PVC tape can be found for around $0.50 to $1.00 at most hardware stores and online platforms. Specialty tapes, such as those intended for high-voltage applications or extreme temperatures, may start at $1.50 and can go up to $5.00 or more per roll.

Purchasing Trends

In recent years, there has been a noticeable shift towards e-commerce for purchasing electrical insulation tape. Online retailers offer competitive prices, bulk purchasing discounts, and a wider variety of products than many physical stores. Consumers are increasingly looking for convenience and cost-effectiveness, driving a trend towards online shopping for electrical supplies.

Conclusion

Understanding the pricing dynamics of electrical insulation tape is essential for both consumers and businesses involved in electrical applications. By considering factors such as material composition, adhesive quality, temperature rating, and brand reputation, purchasers can make informed decisions that balance cost and performance. As the market continues to evolve, staying abreast of trends and changes in pricing will help consumers navigate their options effectively. Whether for small DIY projects or large-scale industrial applications, investing in the right electrical insulation tape can enhance safety and operational efficiency.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025