Understanding Types of Electrical Insulation Tape

Electrical insulation tape is a crucial component in various electrical applications, providing protection and safety in both residential and industrial environments. It is essential to choose the right type of insulation tape depending on the specific needs of a project. Below, we explore the different types of electrical insulation tape and their respective uses.

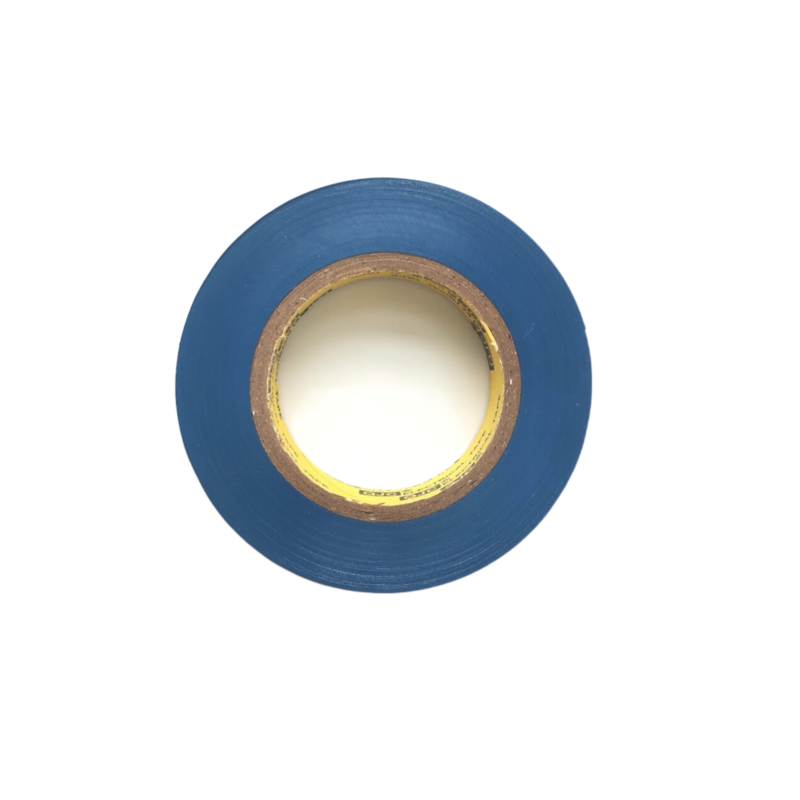

1. PVC Electrical Tape

Polyvinyl chloride (PVC) tape is one of the most commonly used types of electrical insulation tape. It is well-known for its excellent insulating properties, durability, and resistance to moisture and chemicals. PVC tape typically comes in different colors, which can be used for color-coding wires and circuits. This type of tape is suitable for a range of applications, including bundling wires, repairing insulation, and providing strain relief to cables.

Rubber electrical tape is made from a blend of synthetic and natural rubber compounds. It is particularly known for its high dielectric strength, offering superior insulation compared to PVC tape. This tape can stretch and conform to irregular surfaces, making it ideal for wrapping around connectors and complex shapes. It is commonly used in automotive and aviation applications, where a strong and flexible insulation solution is required.

3. Vinyl Electrical Tape

electrical insulation tape types

Vinyl tape, similar to PVC tape, has excellent flexibility and is resistant to abrasion, moisture, and UV rays. It is often used in situations where a reliable, color-coded marking solution is needed for wires and electrical components. Vinyl electrical tape is available in various thicknesses and can withstand a range of temperatures, making it suitable for both indoor and outdoor use.

4. High-Temperature Electrical Tape

High-temperature electrical tape is specifically designed to withstand extreme temperatures, making it ideal for applications involving hot surfaces or high-current electrical components. Typically made from silicone or Mylar, this tape can endure temperatures from -60°C to over 200°C without losing its insulating properties. It is widely used in motor windings, transformers, and other high-heat applications.

5. Self-Fusing Silicone Tape

Self-fusing silicone tape does not contain adhesives; instead, it bonds to itself when wrapped. This unique feature provides a waterproof seal and excellent insulating properties. It is highly resistant to UV rays, making it suitable for outdoor applications. Self-fusing tape is often used for electrical insulation, as well as sealing leaks and repairing hoses.

Conclusion

Choosing the right type of electrical insulation tape depends on the specific requirements of the application, such as temperature tolerance, flexibility, and moisture resistance. Understanding the characteristics and uses of each type can help ensure safety and efficiency in all electrical projects. Whether for home repairs or industrial applications, having the appropriate insulation tape on hand is essential for maintaining electrical integrity and safety.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025