The Rise of Electrical PVC Tape Manufacturers An Overview

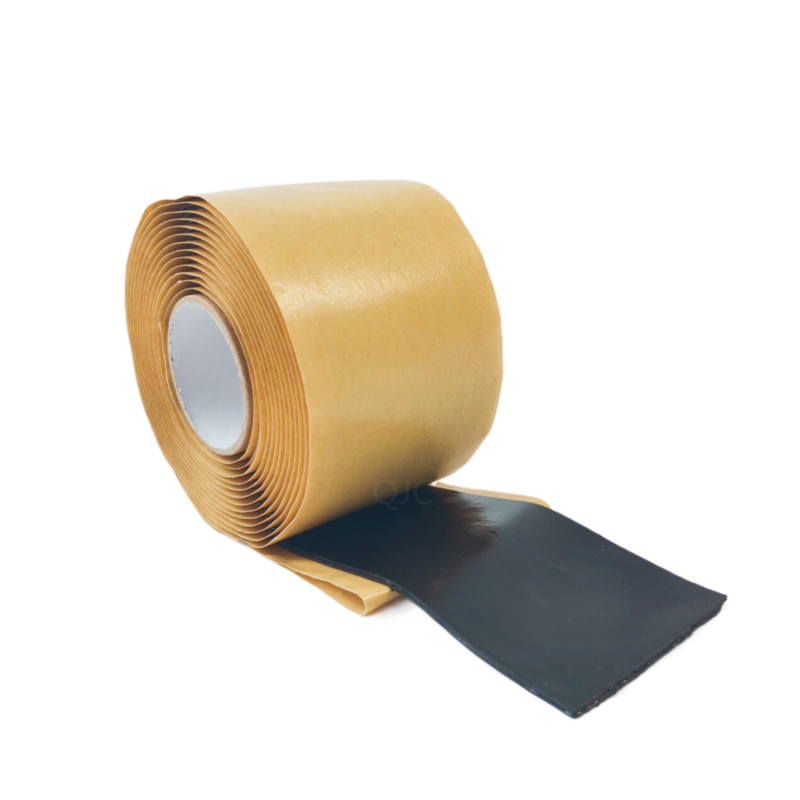

In today’s rapidly evolving electrical industry, the importance of reliable insulation materials cannot be overstated. One such essential material is electrical PVC tape, known for its excellent insulating properties, flexibility, and durability. This versatile tape is commonly used in a variety of applications, from electrical wiring to securing components in automotive and electronic items. As technology progresses, the demand for high-quality electrical PVC tape continues to grow, leading to the emergence of numerous manufacturers in this sector.

Electrical PVC tape is made from polyvinyl chloride, which is a type of plastic that exhibits excellent insulation characteristics. This makes it ideal for protecting electrical connections from moisture, dust, and other environmental factors that can compromise performance. Manufacturers in the industry focus on creating tapes that not only comply with international standards but also meet the specific needs of their clients.

The Rise of Electrical PVC Tape Manufacturers An Overview

In response to this demand, manufacturers are investing in state-of-the-art production facilities, leading to enhanced efficiency and product quality. They are also adopting modern technologies, including automated processes and advanced testing equipment, to ensure that the electrical PVC tapes they produce meet stringent quality standards. Furthermore, many manufacturers are focusing on sustainability, exploring eco-friendly materials and processes that reduce environmental impact.

electrical pvc tape manufacturers

Competition in the electrical PVC tape industry has intensified as both established companies and new entrants strive to capture market share. Manufacturers are increasingly differentiating their products by offering specialized adhesives, varying thicknesses, and a range of colors to cater to diverse customer needs. Some companies even provide customized solutions, allowing clients to specify requirements such as length, width, and tensile strength.

Another factor driving the rise of electrical PVC tape manufacturers is the growing awareness of safety regulations. Organizations and industries are now more inclined to adhere to safety standards, particularly in electrical installations. This trend encourages manufacturers to produce tapes that not only comply with these regulations but also enhance the safety of end-users. Certifications from recognized institutions can play a significant role in establishing credibility and trust in the marketplace.

Moreover, the rise of e-commerce has transformed how manufacturers promote and distribute electrical PVC tape. Many companies are creating online platforms where customers can easily browse products, compare specifications, and place orders directly. This not only improves accessibility for customers but also allows manufacturers to reach a broader audience, including international markets.

In conclusion, the landscape of electrical PVC tape manufacturers is rapidly evolving, driven by technological advancements, increasing demand for electrical safety, and a competitive marketplace. As industries continue to grow and diversify, the focus on quality, innovation, and sustainability will remain paramount. Manufacturers that prioritize these aspects will likely thrive, ensuring that electrical PVC tape remains a fundamental resource in the electrical industry. With the combination of safety, performance, and customer-centric solutions, the future of electrical PVC tape manufacturing looks promising, paving the way for further advancements and applications in various sectors.

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025